.... but I was blinded by your unknowledgment of the boolean in swx, swx allows the extruded cut through sketch 3d, you don't know this me put the doubt on all the atres you wrote , allego image and ......................... can you make it inventor?

Hello, if I don't understand your tone: Don't you know this me? ) question all the others you have written, let's go further.

We're divading, but I think it can be tolerated, at least I hope.

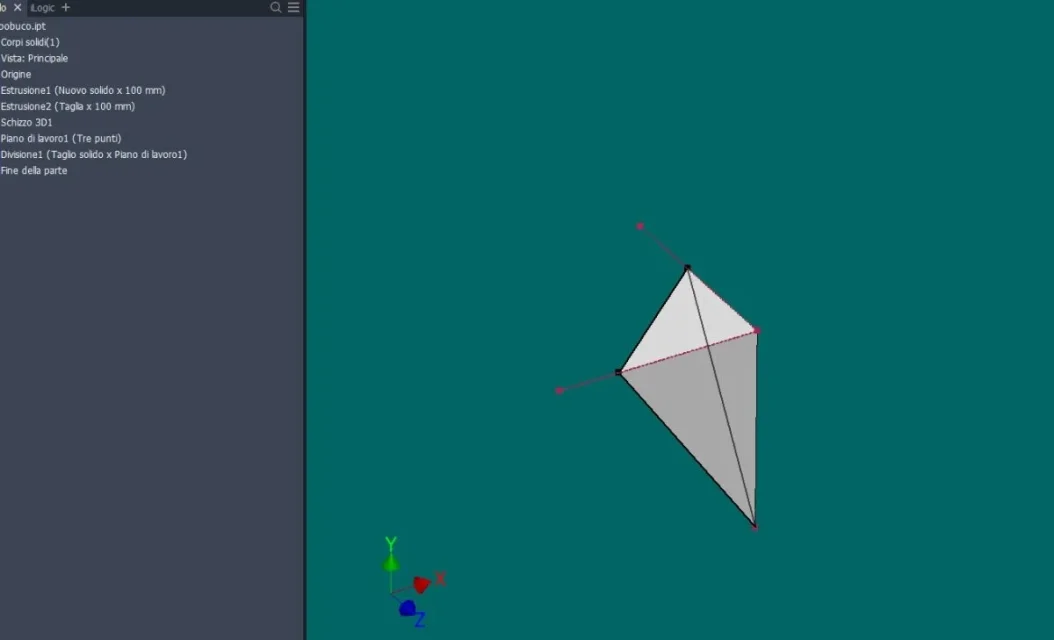

not to disappoint you, but how can that be a boolean operation? the same that you write to be an extruded cut along one corner guide among other things, detail anything but negligible...., in fact else can not be.

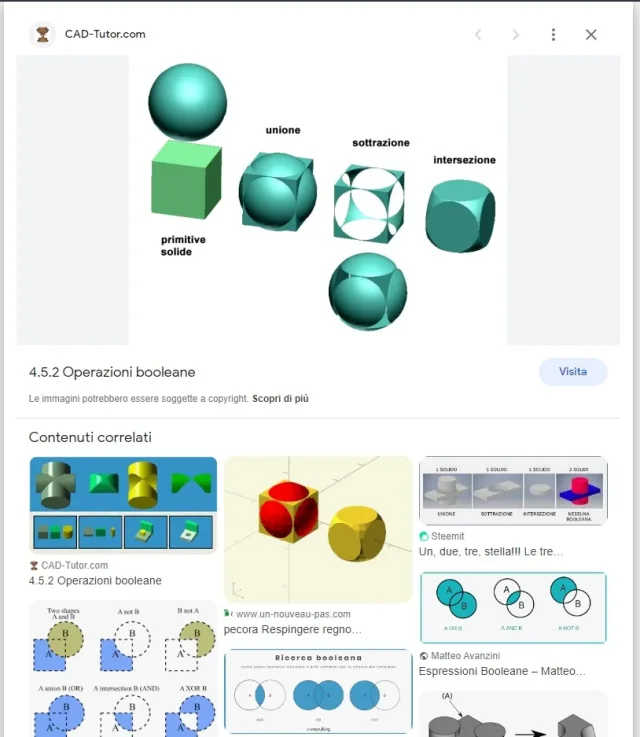

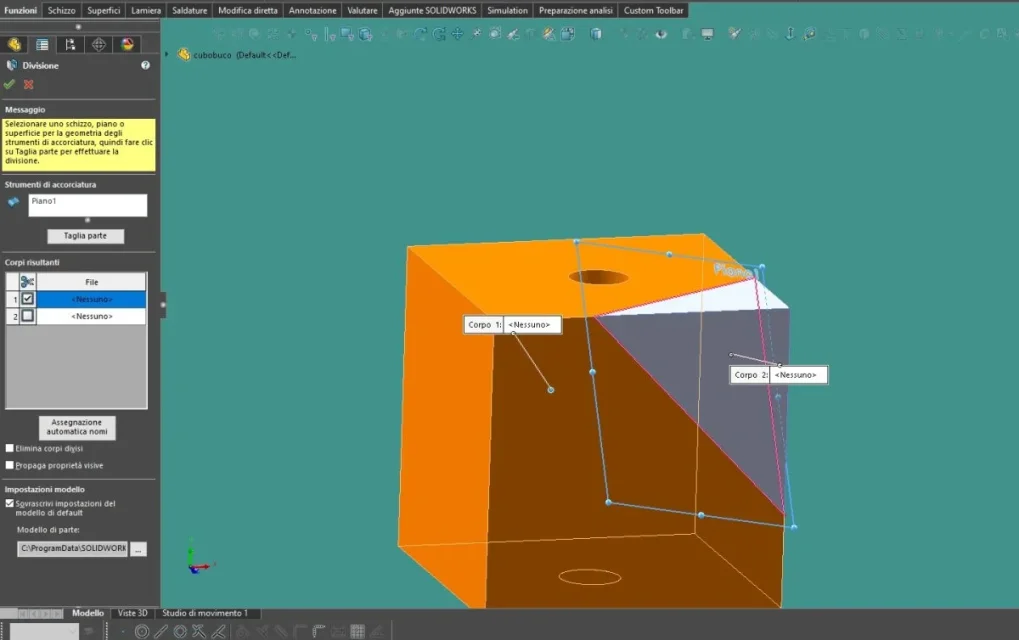

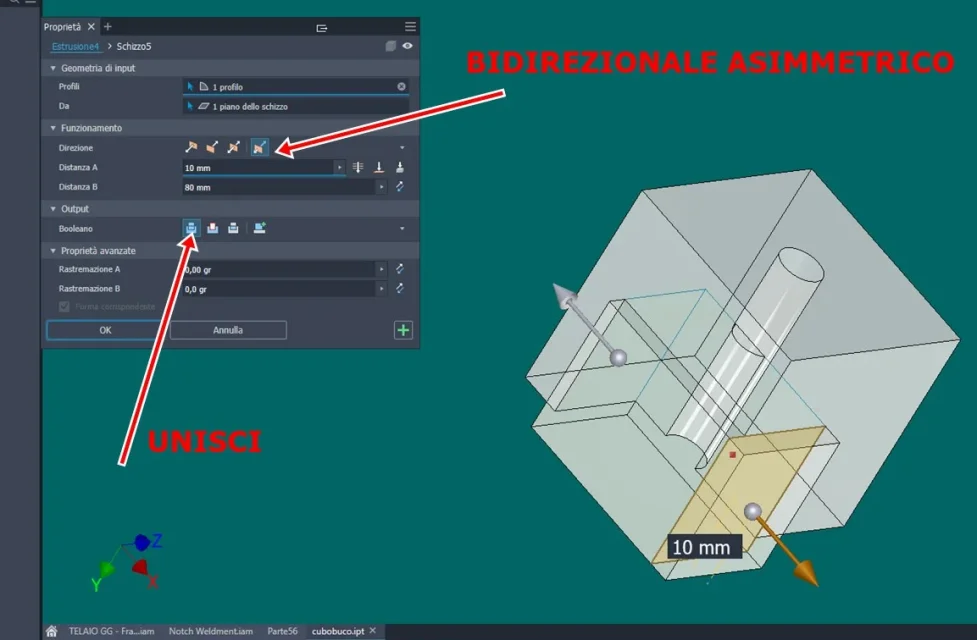

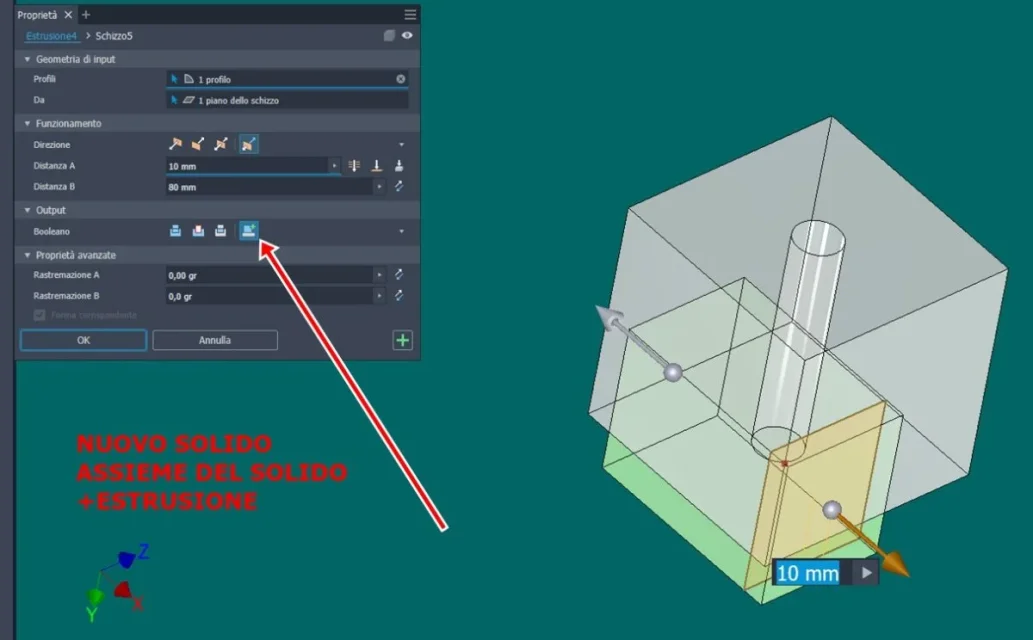

Boolean operations are something else, a simple example is found in the attached image, which as I wrote can be done with matching command, not easy to use in my opinion.

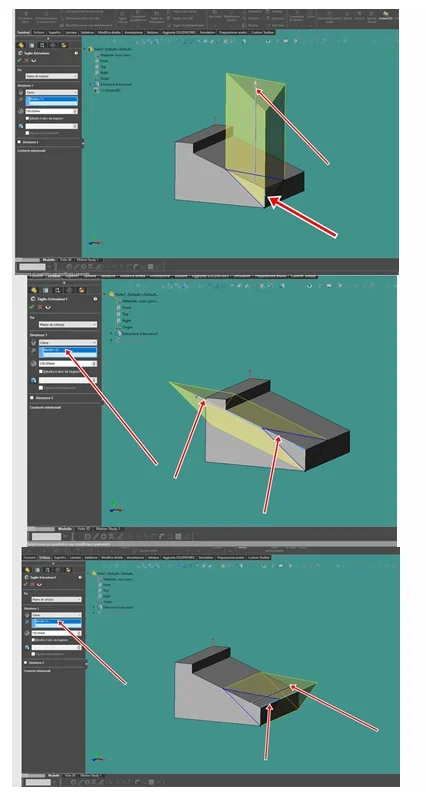

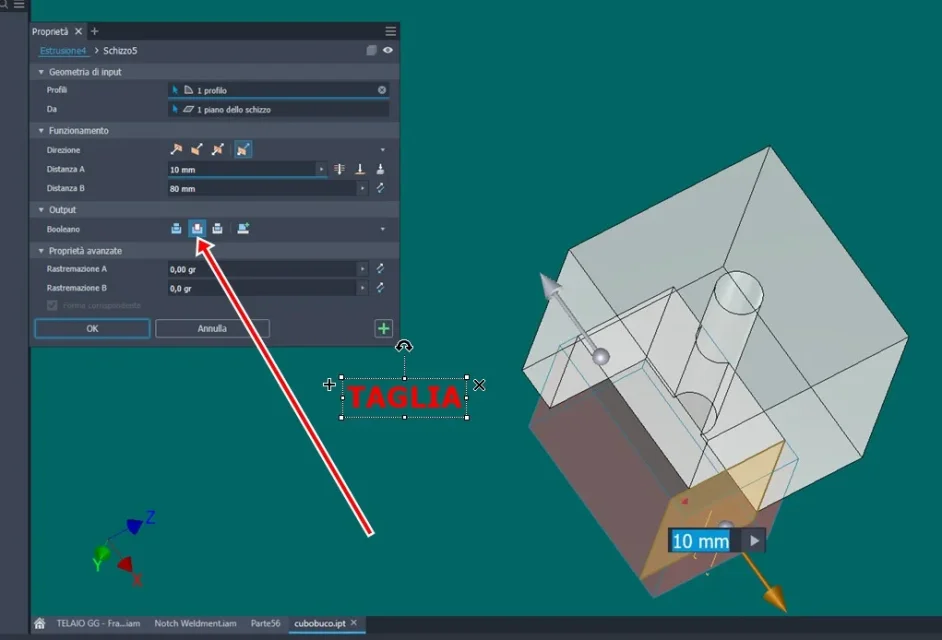

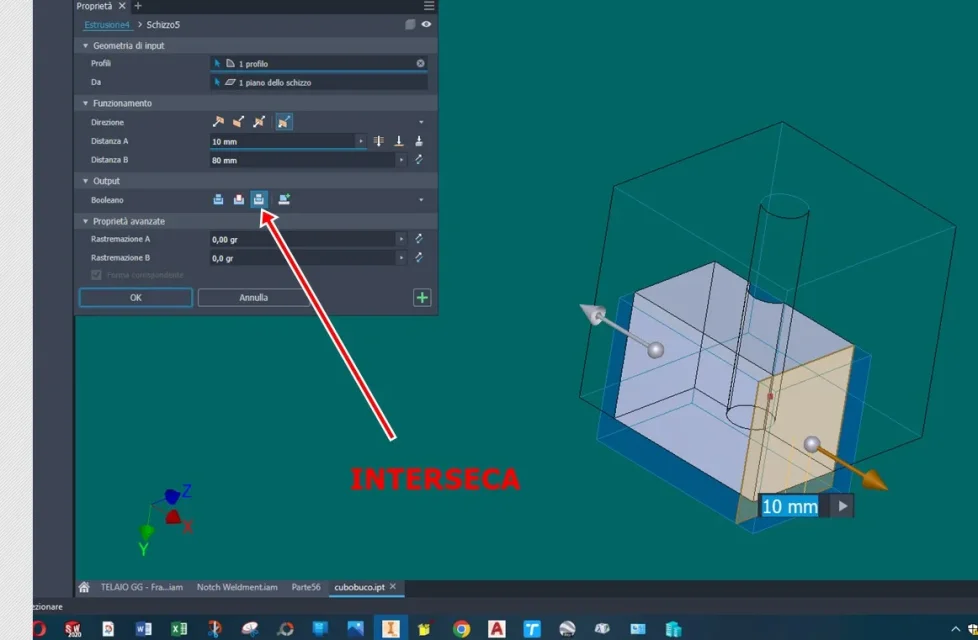

sw does not allow operations of that type performed as in inv, it would be beautiful but unfortunately sw does not manage to make it, are operations much more articulated in sw. the only way to do a boolean operation, I repeat, is what I mentioned, made by the command insert >> > functions > pairs. here you will find a few examples:

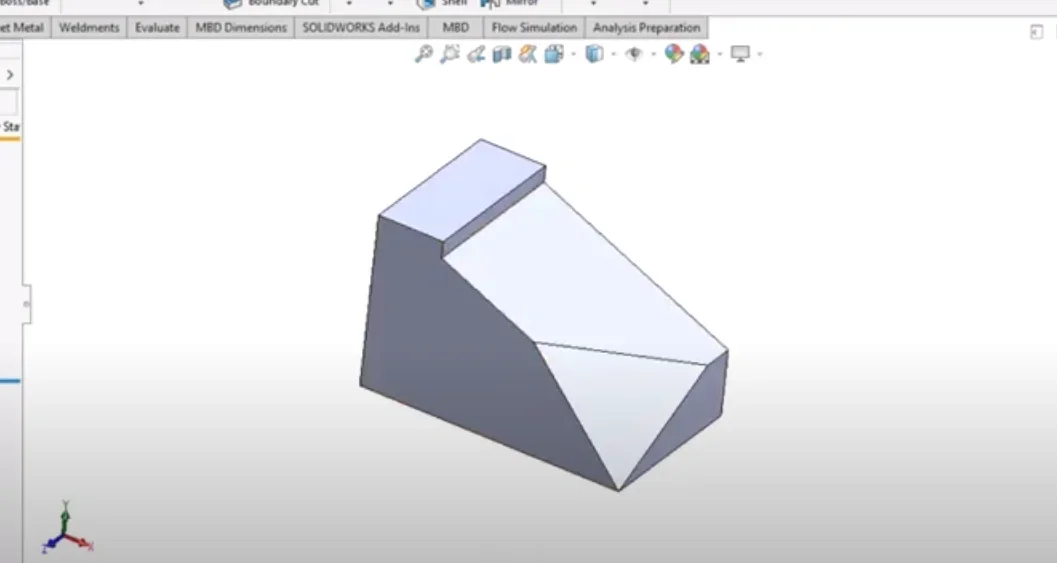

this is the best example, the simplest.

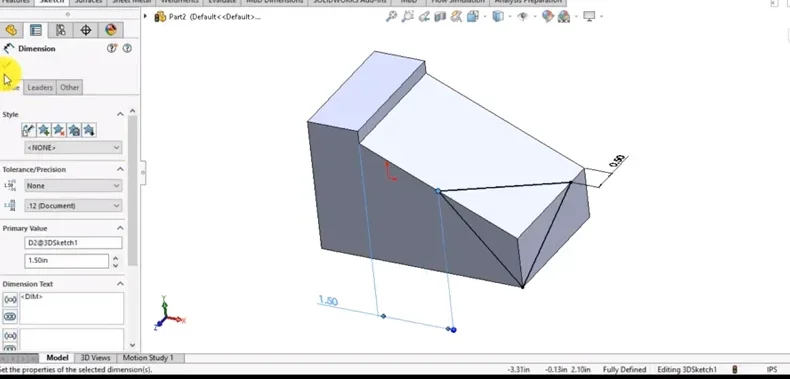

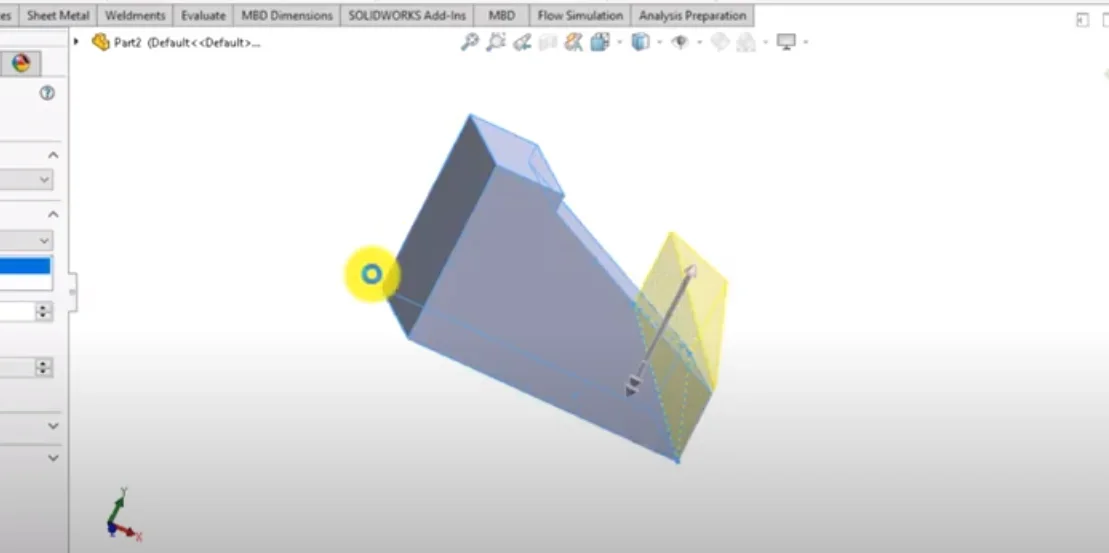

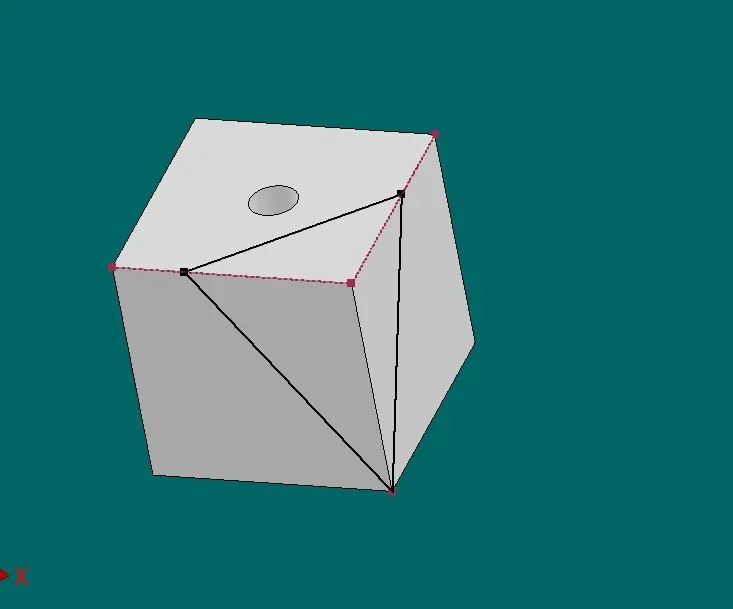

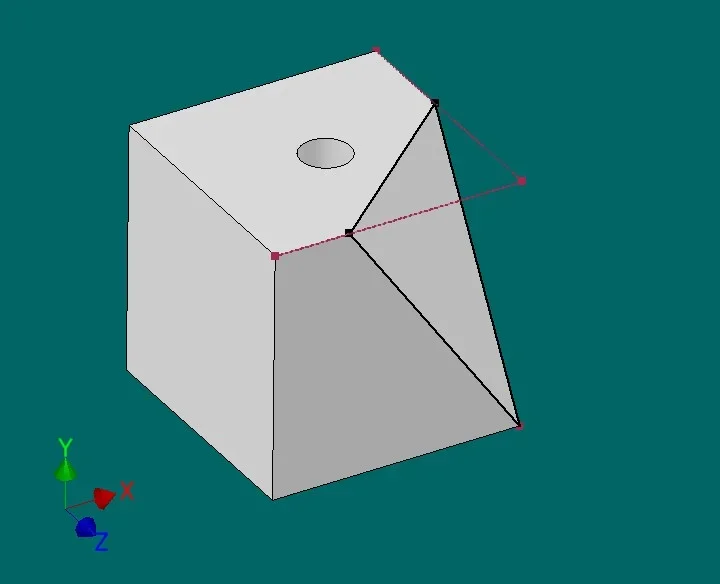

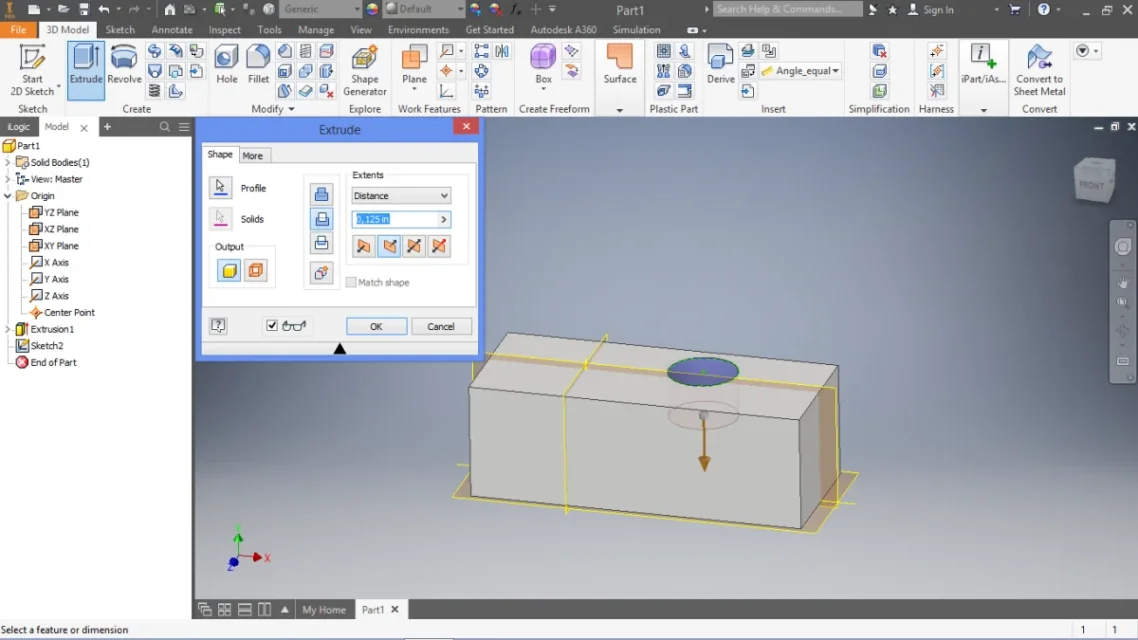

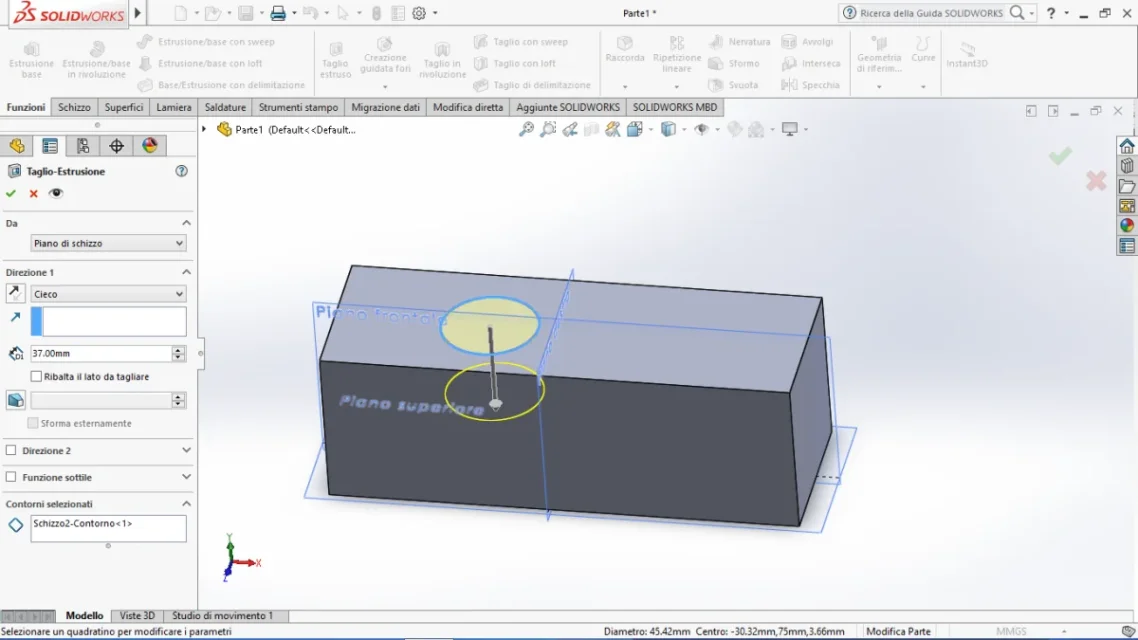

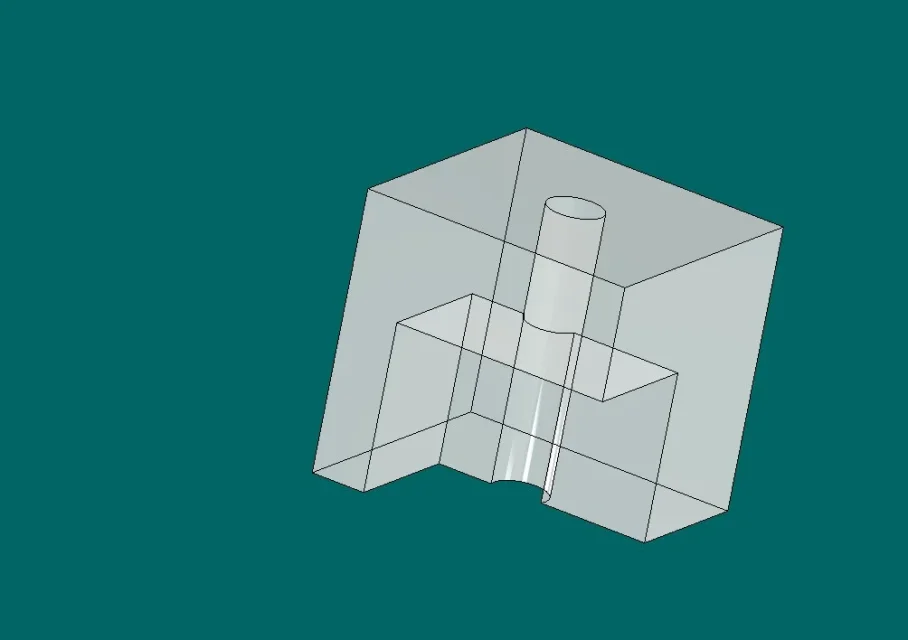

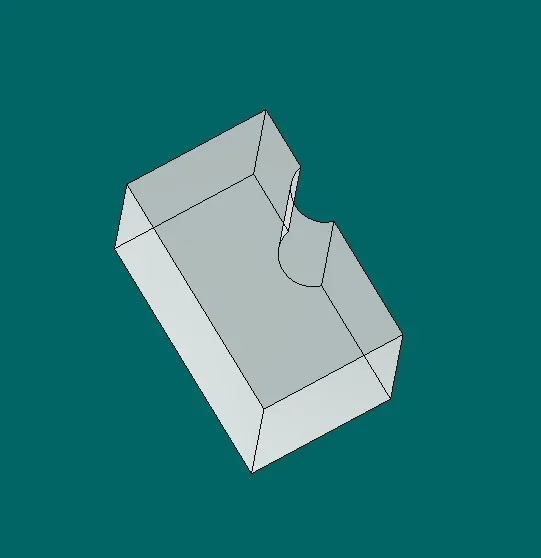

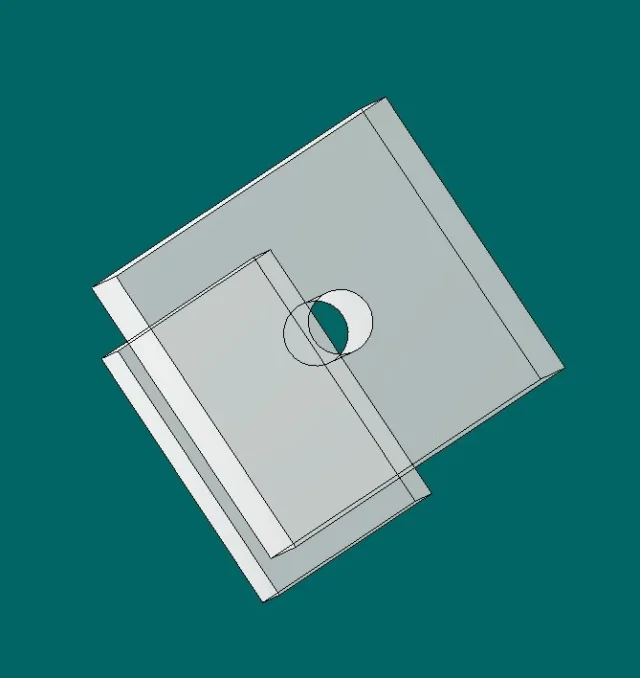

in the two images the equivalent in inv of what nothing but in sw an extruded cut.

He does.

However, point in favor of sw, a similar result is obtained with the command much more powerful and flexible divides that engages a plane, or a more or less complex surface, as a cutting tool. This command allows you to always decide what to hold and what to remove, even after applying it, with the additional possibility of generating two bodies that you can save them with different names, in the inv instead will remain only one, like highlander, even if to say the true inv is able to generate two but not simultaneously as sw, 1/2 point in favor.... .

forgives punctuality: sw has no command within which the Boolean word appears.

Hi.