meccanicamg

Guest

here is an approach to calculate the torque at the crank of your biella-manovella mechanism:

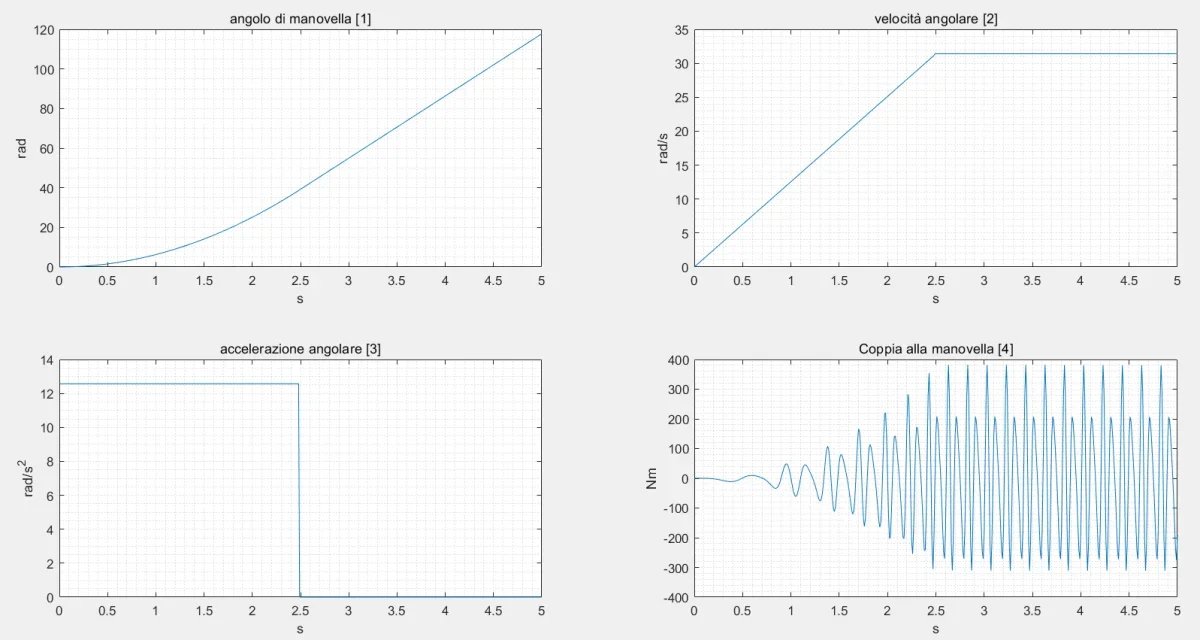

1. calculation of angular acceleration:* conversion of turns per minute to radiant per second: 1 min/60 s ≈ 31.42 rad/s

* calculation of angular acceleration: α = ω / t = 31.42 rad/s / 2.5 s ≈ 12.57 rad/s2

2. calculation of force on the piston:* determination of the force necessary to accelerate the mass: f = m

* calculation of linear acceleration of the piston: this is a more complex part because the acceleration of the piston varies during the rotation of the crank. for an approximate estimate, you can consider the maximum acceleration of the piston, which occurs when the crank is perpendicular to the biella. you can use a more detailed film analysis for a more precise calculation.

3. calculation of the tangential force on the handle:* use of the transmission ratio: the force on the piston is transmitted to the crank through the biella. the transmission ratio between the force on the piston and the tangential force on the handle depends on the geometry of the mechanism (length of the biella and the beam of the handle).

* Tangential force calculation: f_tangenziale = f_pistone * (r_manovella / l_biella)

4. calculation of the torque to the handle:* torque definition: the couple is the product of the tangential force for the crank radius.

* torque calculation: τ =

summary formulas:

* ω = 2πn / 60

* α ω / t

* f = m * a

* f_tangenziale = f_pistone * (r_manovella / l_biella)

* τ = f_tangenous * r_manovella

comments:

* approximations: this calculation provides an approximate estimate of the pair. for a more precise result, it is necessary to consider the complete kinematic analysis of the biella-manovella mechanism, taking into account the variation of the acceleration of the piston during the rotation of the crank.

* Other factors: Other factors such as friction, biella mass and losses in the mechanism can affect the actual torque required.

precise calculation of the acceleration of the piston in a biella-manovella mechanism requires a more in-depth analysis of the kinematics.

formulas and considerations:to determine the acceleration of the piston at every moment, it is necessary to consider the geometry of the mechanism and the angular speed of the handle.* piston position:

the position of the piston (s) in relation to the upper dead point can be expressed according to the angle of rotation of the crank (θ) and the lengths of the biella (l) and the crank (r):

(cos(θ) + √(l2 - r2sin2(θ)))

* piston speed:

derived the position compared to time, you get the piston speed:

v = ds/dt = ω * r * (sin(θ) + (r * sin(θ) * cos(θ) / √(l2 - r2sin2(θ)))

where ω is the angle speed of the crank.

* Piston acceleration:

further resulting the speed compared to the time, you get the acceleration of the piston:

a = dv/dt = ω2 * r * (cos(θ) + (r * (cos2(θ) - sin2(θ)) / √(l2 - r2sin2(θ)) + (r3 * sin2(θ) * cos(θ)) / (l2 - r2sin2(θ)))^(3/2))

comments:

* complexity of the equation: As you can see, the acceleration equation is quite complex and contains trigonometric terms.

* variation of acceleration: the acceleration of the piston varies continuously during the rotation of the crank, reaching maximum and minimum values at certain positions.

* graphs: to better display the variation of acceleration over time, it is useful to graphically represent acceleration according to the angle of rotation of the handle.

numerical calculations:

to obtain specific numerical values for your case, you can:

* Replace numerical values: insert r, l, ω and θ values into equations.

* use a spreadsheet: use a program like excel or an online spreadsheet to calculate acceleration for different values of θ.

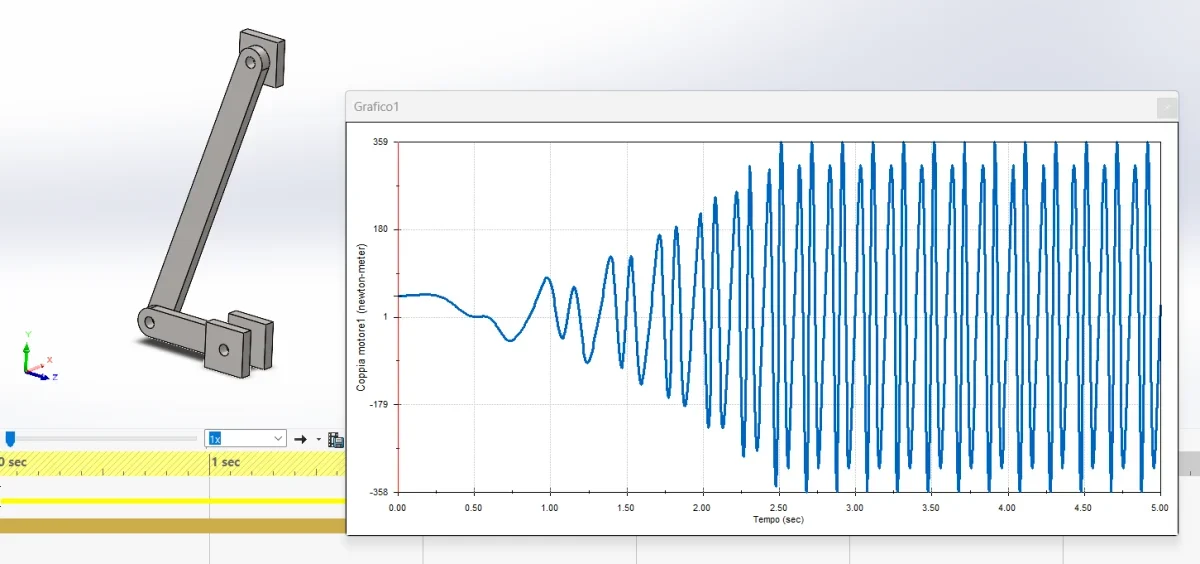

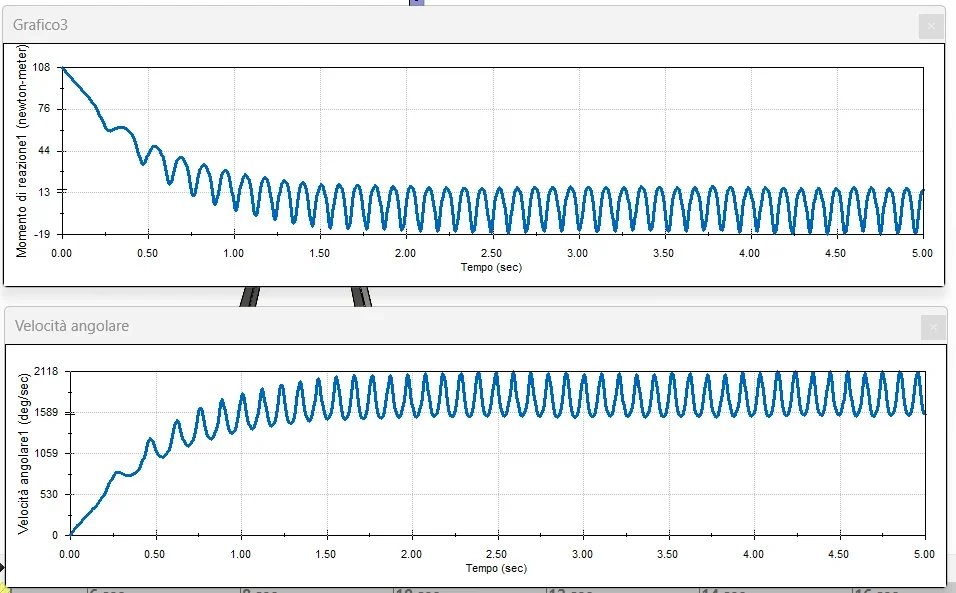

* use a simulation software: software such as matlab or cad programs can be used to perform dynamic simulations of the mechanism and get detailed graphics of acceleration.

Further considerations:

* rotation angle: θ angle can vary from 0 to 2 radiant for a complete turn of the crank.

* measuring unit: Be sure to use consistent measuring units (for example, meters for lengths, radiant for angles and seconds for time).

* approximations: in some cases, approximations can be used to simplify calculations, but it is important to evaluate the accuracy of approximations according to the specific application.

do everything with excel and you will see that you will be able to track the charts you need and then from here overlap the engine curve power/turns and torque/turns and you will assess whether it's okay or not.

Remember that depending on the starting angle you will still get different charts and torques to start different.

in all this was considered in the first unaffected approximation: friction and inertia.

built the basic calculation sheet you can enrich it with new considerations.

1. calculation of angular acceleration:* conversion of turns per minute to radiant per second: 1 min/60 s ≈ 31.42 rad/s

* calculation of angular acceleration: α = ω / t = 31.42 rad/s / 2.5 s ≈ 12.57 rad/s2

2. calculation of force on the piston:* determination of the force necessary to accelerate the mass: f = m

* calculation of linear acceleration of the piston: this is a more complex part because the acceleration of the piston varies during the rotation of the crank. for an approximate estimate, you can consider the maximum acceleration of the piston, which occurs when the crank is perpendicular to the biella. you can use a more detailed film analysis for a more precise calculation.

3. calculation of the tangential force on the handle:* use of the transmission ratio: the force on the piston is transmitted to the crank through the biella. the transmission ratio between the force on the piston and the tangential force on the handle depends on the geometry of the mechanism (length of the biella and the beam of the handle).

* Tangential force calculation: f_tangenziale = f_pistone * (r_manovella / l_biella)

4. calculation of the torque to the handle:* torque definition: the couple is the product of the tangential force for the crank radius.

* torque calculation: τ =

summary formulas:

* ω = 2πn / 60

* α ω / t

* f = m * a

* f_tangenziale = f_pistone * (r_manovella / l_biella)

* τ = f_tangenous * r_manovella

comments:

* approximations: this calculation provides an approximate estimate of the pair. for a more precise result, it is necessary to consider the complete kinematic analysis of the biella-manovella mechanism, taking into account the variation of the acceleration of the piston during the rotation of the crank.

* Other factors: Other factors such as friction, biella mass and losses in the mechanism can affect the actual torque required.

precise calculation of the acceleration of the piston in a biella-manovella mechanism requires a more in-depth analysis of the kinematics.

formulas and considerations:to determine the acceleration of the piston at every moment, it is necessary to consider the geometry of the mechanism and the angular speed of the handle.* piston position:

the position of the piston (s) in relation to the upper dead point can be expressed according to the angle of rotation of the crank (θ) and the lengths of the biella (l) and the crank (r):

(cos(θ) + √(l2 - r2sin2(θ)))

* piston speed:

derived the position compared to time, you get the piston speed:

v = ds/dt = ω * r * (sin(θ) + (r * sin(θ) * cos(θ) / √(l2 - r2sin2(θ)))

where ω is the angle speed of the crank.

* Piston acceleration:

further resulting the speed compared to the time, you get the acceleration of the piston:

a = dv/dt = ω2 * r * (cos(θ) + (r * (cos2(θ) - sin2(θ)) / √(l2 - r2sin2(θ)) + (r3 * sin2(θ) * cos(θ)) / (l2 - r2sin2(θ)))^(3/2))

comments:

* complexity of the equation: As you can see, the acceleration equation is quite complex and contains trigonometric terms.

* variation of acceleration: the acceleration of the piston varies continuously during the rotation of the crank, reaching maximum and minimum values at certain positions.

* graphs: to better display the variation of acceleration over time, it is useful to graphically represent acceleration according to the angle of rotation of the handle.

numerical calculations:

to obtain specific numerical values for your case, you can:

* Replace numerical values: insert r, l, ω and θ values into equations.

* use a spreadsheet: use a program like excel or an online spreadsheet to calculate acceleration for different values of θ.

* use a simulation software: software such as matlab or cad programs can be used to perform dynamic simulations of the mechanism and get detailed graphics of acceleration.

Further considerations:

* rotation angle: θ angle can vary from 0 to 2 radiant for a complete turn of the crank.

* measuring unit: Be sure to use consistent measuring units (for example, meters for lengths, radiant for angles and seconds for time).

* approximations: in some cases, approximations can be used to simplify calculations, but it is important to evaluate the accuracy of approximations according to the specific application.

do everything with excel and you will see that you will be able to track the charts you need and then from here overlap the engine curve power/turns and torque/turns and you will assess whether it's okay or not.

Remember that depending on the starting angle you will still get different charts and torques to start different.

in all this was considered in the first unaffected approximation: friction and inertia.

built the basic calculation sheet you can enrich it with new considerations.

Last edited: