Looz

Guest

Hello, guys.

I have a problem about saving the designs and assigning the name.

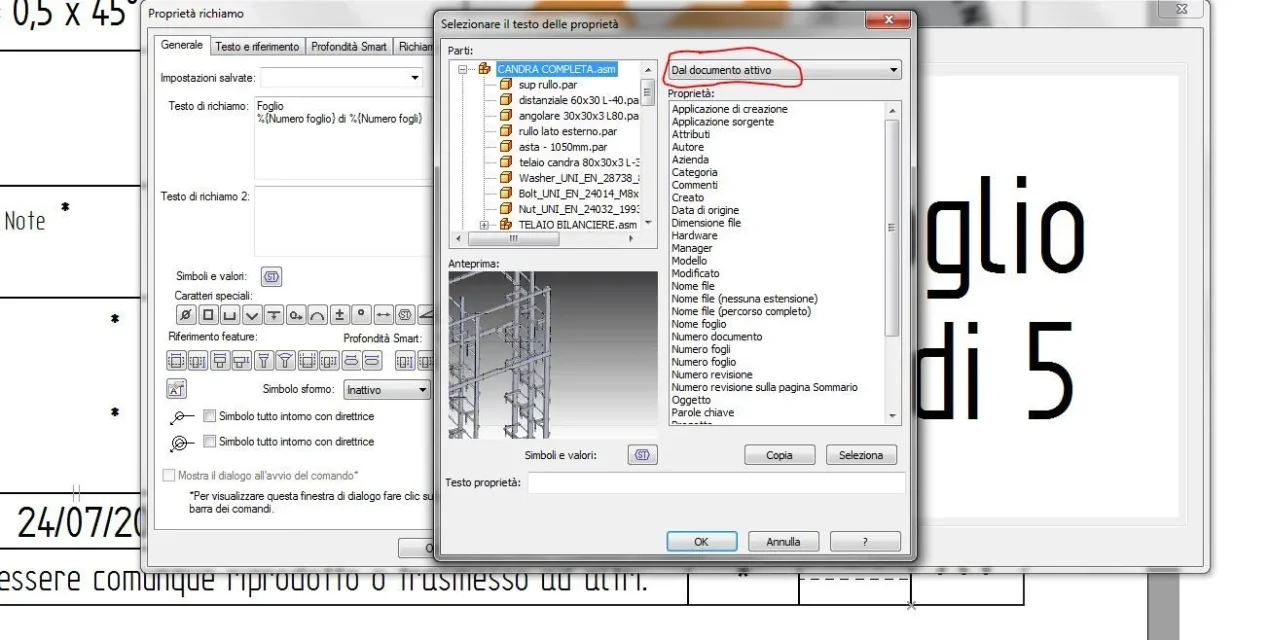

In practice I created a formula on the cartiglio that relates the name of the file (in this case the code of the assieme a1401-1) with the sheet number.

so just add a sheet that automatically get the component name progressively with the sheets.

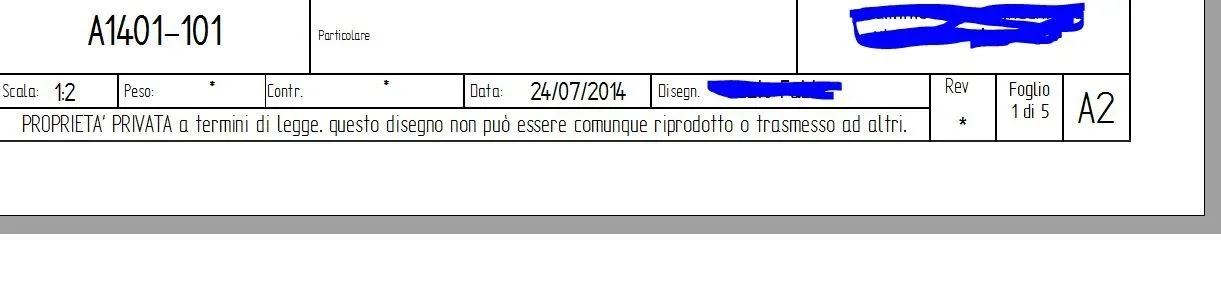

so just add a sheet that automatically get the component name progressively with the sheets. the problem lies in the fact that when I go to print or save in pdf the numbering of the sheets is canceled and on each sheet remains the word "sheet 1 of 5" as if it reported all the sheets to the first.

the problem lies in the fact that when I go to print or save in pdf the numbering of the sheets is canceled and on each sheet remains the word "sheet 1 of 5" as if it reported all the sheets to the first.

Therefore the name of the compost always remains "01" final on all sheets and the speech made before is less. It seems strange that it does not keep the numbering of the leaves when I save all the drawings together!

It seems strange that it does not keep the numbering of the leaves when I save all the drawings together!

in the pdf rescue options I found nothing that can solve this.

So basically, do you know a method to save/print a necklace of sheets maintaining the progressive numbering of solid edge sheets?

or do you usually make all drawings on individual dft files and then in saving you assign a new name to the drawing?

as always thanks in advance!:biggrin:

I have a problem about saving the designs and assigning the name.

In practice I created a formula on the cartiglio that relates the name of the file (in this case the code of the assieme a1401-1) with the sheet number.

so just add a sheet that automatically get the component name progressively with the sheets.

so just add a sheet that automatically get the component name progressively with the sheets. the problem lies in the fact that when I go to print or save in pdf the numbering of the sheets is canceled and on each sheet remains the word "sheet 1 of 5" as if it reported all the sheets to the first.

the problem lies in the fact that when I go to print or save in pdf the numbering of the sheets is canceled and on each sheet remains the word "sheet 1 of 5" as if it reported all the sheets to the first.Therefore the name of the compost always remains "01" final on all sheets and the speech made before is less.

It seems strange that it does not keep the numbering of the leaves when I save all the drawings together!

It seems strange that it does not keep the numbering of the leaves when I save all the drawings together!in the pdf rescue options I found nothing that can solve this.

So basically, do you know a method to save/print a necklace of sheets maintaining the progressive numbering of solid edge sheets?

or do you usually make all drawings on individual dft files and then in saving you assign a new name to the drawing?

as always thanks in advance!:biggrin: