Ing.Vedder

Guest

Hello everyone,

I should size a couple of bearings for a wheel under heavy loads but I would like an opinion.

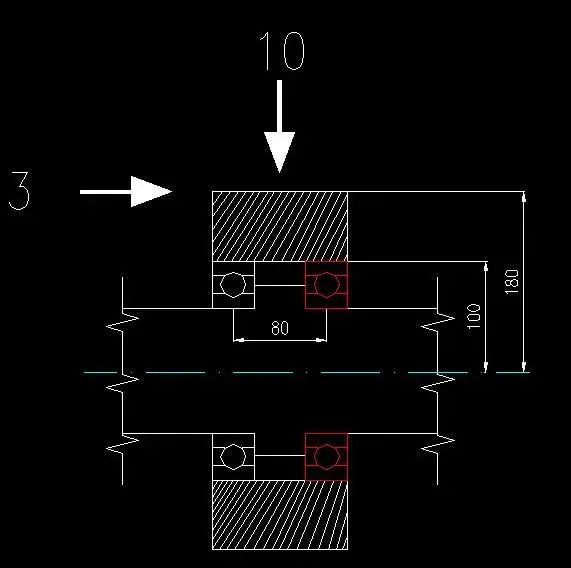

on the wheel (in section) weighs a radial load of 10 tons and an axial load of 3 tons.

the radial load doesn't give me big problems and it also distributes on both bearings.

the axial load instead is applied on the edge of the wheel so I expect that the opposite bearing on the side of the aplication of the load (that drawn in red) receives an amplification of the radial load due to the moments that are established.

in the first line I had reasoned in this way.

moment = 3x180 = 540 [T*mm] therefore 540 [T*mm]/80 [mm]= 6.75 [tonn]in this way there would be a radial load on the most "loaded" bearing of (10/2)+6.75=11.75 ton.

To reason in my opinion is wrong and too cautionary, the arms of moments are not real.

how would you behave to find radial load and axial load acting on the red bearing?

Many thanks to all

I should size a couple of bearings for a wheel under heavy loads but I would like an opinion.

on the wheel (in section) weighs a radial load of 10 tons and an axial load of 3 tons.

the radial load doesn't give me big problems and it also distributes on both bearings.

the axial load instead is applied on the edge of the wheel so I expect that the opposite bearing on the side of the aplication of the load (that drawn in red) receives an amplification of the radial load due to the moments that are established.

in the first line I had reasoned in this way.

moment = 3x180 = 540 [T*mm] therefore 540 [T*mm]/80 [mm]= 6.75 [tonn]in this way there would be a radial load on the most "loaded" bearing of (10/2)+6.75=11.75 ton.

To reason in my opinion is wrong and too cautionary, the arms of moments are not real.

how would you behave to find radial load and axial load acting on the red bearing?

Many thanks to all