John75

Guest

Good morning to all,

I am mainly a fan of the DIY in the field of wood and metals, but now by necessity I have come across electric parts where purtoppo are ignorant to the maximum and therefore I ask for help if possible.

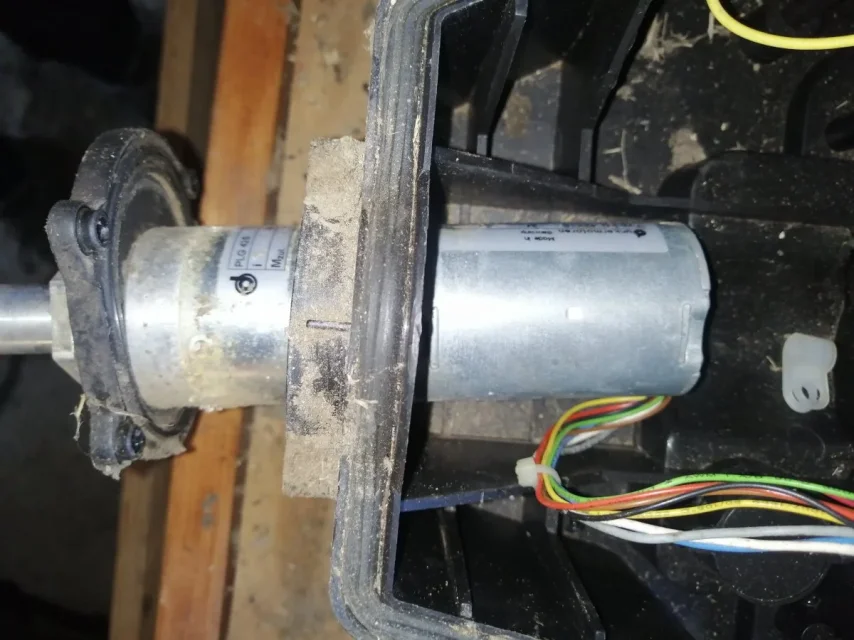

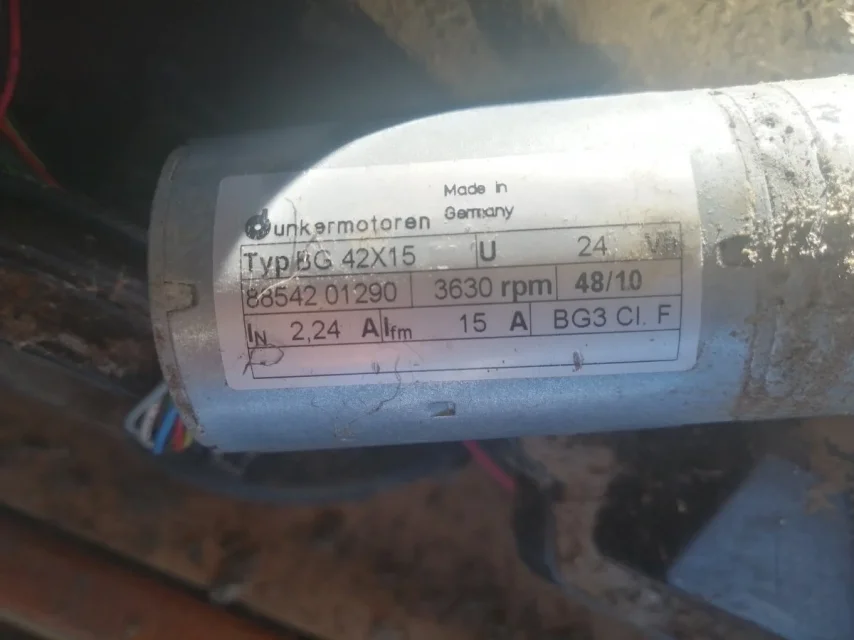

I now explain to the best, from an old electric robot cutter I have recovered 2 brushless motors (after I try to attach photos ) I wanted to recover them for a two-wheeled cart that I built and do it motorized, reading on various tutorials I have come more confusion than other, I have seen that I need a power station and an accelerator to make it work , but I do not understand that power station is necessary.

thanks early for those who can help me

I am mainly a fan of the DIY in the field of wood and metals, but now by necessity I have come across electric parts where purtoppo are ignorant to the maximum and therefore I ask for help if possible.

I now explain to the best, from an old electric robot cutter I have recovered 2 brushless motors (after I try to attach photos ) I wanted to recover them for a two-wheeled cart that I built and do it motorized, reading on various tutorials I have come more confusion than other, I have seen that I need a power station and an accelerator to make it work , but I do not understand that power station is necessary.

thanks early for those who can help me