Hope1

Guest

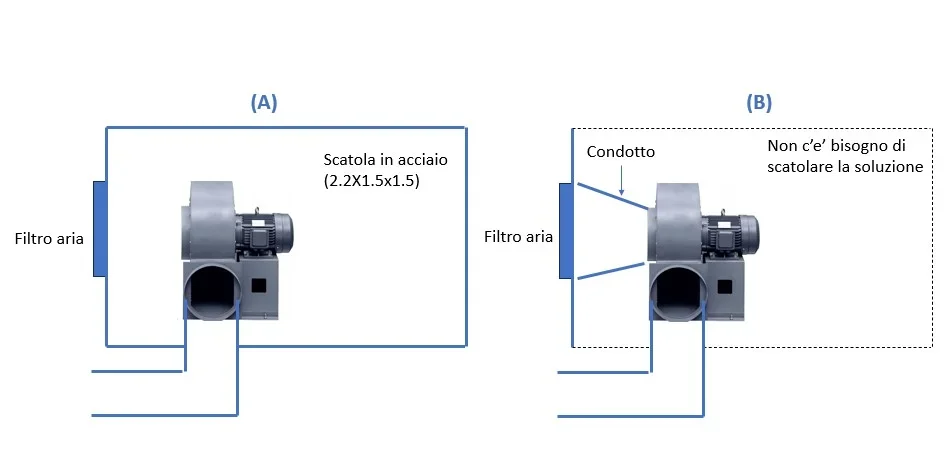

Good morning, I have a question about installing a centrifugal fan (motor about 30kw).

the solution (b) with duct between vesilar input and filter and without external box was challenged.

The solution (a) has been told to me is better - but no one has the time to tell me why (and I am not expert at all I would like to understand).

according to me:

(a) creates vacuum in the box increasing the load losses in input to the fan and the steel box increases the weight of the machinery where it is to be installed.

(a) I don't understand if the electric motor is well refurbished.

(b) does not have (a) problems

(b) requires more attention to mounting for tolerances etc.

(b) the load on the duct between filter and veniler can be elevated by vacuum effect

If (a) is a typical installation for industrial fans I make one reason and step by step - I just want to have a second feedback from you.

thanks to all (even only for reading the message).

the solution (b) with duct between vesilar input and filter and without external box was challenged.

The solution (a) has been told to me is better - but no one has the time to tell me why (and I am not expert at all I would like to understand).

according to me:

(a) creates vacuum in the box increasing the load losses in input to the fan and the steel box increases the weight of the machinery where it is to be installed.

(a) I don't understand if the electric motor is well refurbished.

(b) does not have (a) problems

(b) requires more attention to mounting for tolerances etc.

(b) the load on the duct between filter and veniler can be elevated by vacuum effect

If (a) is a typical installation for industrial fans I make one reason and step by step - I just want to have a second feedback from you.

thanks to all (even only for reading the message).