Echindo

Guest

Good morning.

I'm working on a wagon that will have to transport 150 tons on rail. the carriage will flow on a100 burback rails with external diameter wheels of 500 mm.

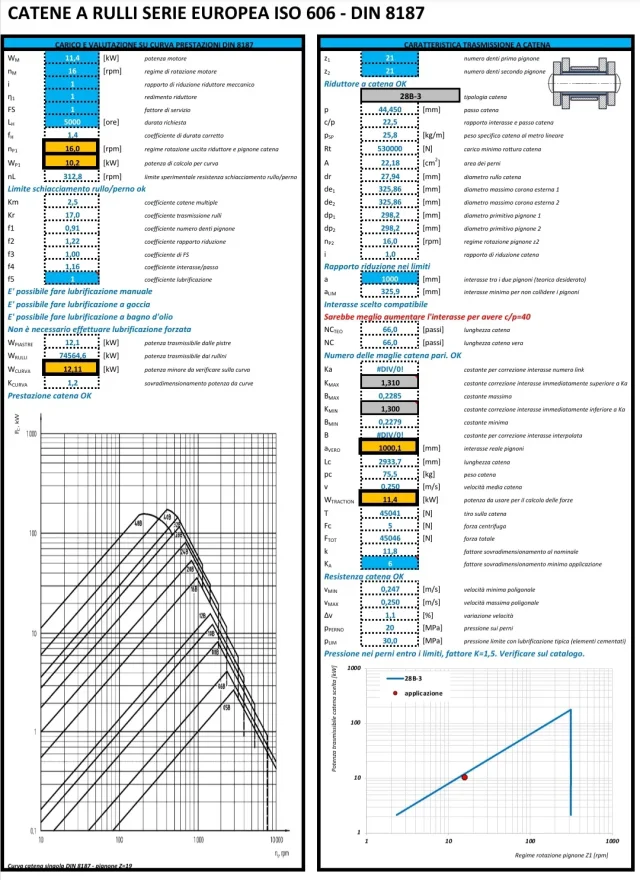

to ensure the possibility of driving the cart in case of failures, I chose to use an epicycloidal reducer and I wanted to use a chain to transmit the torque to the wheels.

the carriage will have 4 wheels, all drive, with two gear motors that will transmit the torque. considering a maximum slope of 3% and a speed of 1.5 km/h I have a torque to the single wheel of 3410 nm.

you could please explain to me the size of the chain transmission, in which diameter, tooth number and everything is chosen.

Thank you.

I'm working on a wagon that will have to transport 150 tons on rail. the carriage will flow on a100 burback rails with external diameter wheels of 500 mm.

to ensure the possibility of driving the cart in case of failures, I chose to use an epicycloidal reducer and I wanted to use a chain to transmit the torque to the wheels.

the carriage will have 4 wheels, all drive, with two gear motors that will transmit the torque. considering a maximum slope of 3% and a speed of 1.5 km/h I have a torque to the single wheel of 3410 nm.

you could please explain to me the size of the chain transmission, in which diameter, tooth number and everything is chosen.

Thank you.