gola

Guest

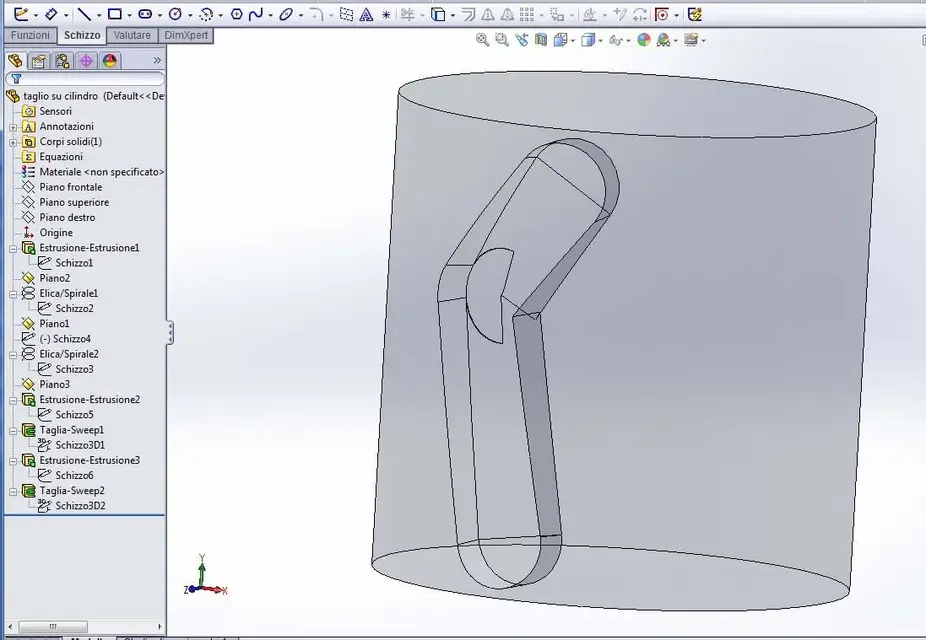

Hi, my name is Matteo. I'm a solid works teacher. I'll tell you what I want to do. I designed a cylinder diameter 100 with length mm100, I created another cylinder diameter 20 perpendicular to the previous (as if it were a milling) I placed it on a d.80, now I have to create a path advancing for mm50 and rotate the cylinder d.100 of 11.5gradi, after I have to move again of mm25 and rotate the cylinder d.100 of 22.5 degrees from the opposite pin.how do I?

change of moderator:

removed email address. responses and suggestions must be public, the purpose of a forum is to exchange information between multiple users.

change of moderator:

removed email address. responses and suggestions must be public, the purpose of a forum is to exchange information between multiple users.

Last edited by a moderator: