max2

Guest

Good morning to all colleagues.

I am not very experienced in tapes (or is it said carpets?) of transport, and I find myself to draw one that, without special attention, they tell me will not stand on track.

If someone has experience, even some simple advice would help me a lot.

Thank you.

I describe the monster.

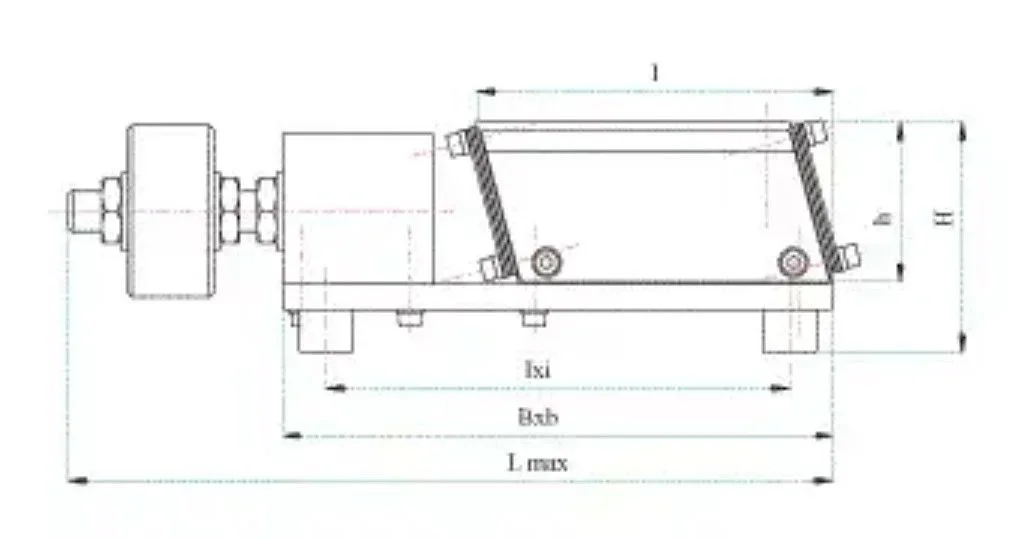

must transfer bulk food, from oven, rather friable, from a tape to another tape. both tapes have rollers of diameter large, 150 and 240 mm diameter. their centers are 500 mm. mat widths : upstream 850 mm and downstream 820 mm. that downstream has also containment edges. the minimum speed is 2 m/min and the maximum 4 m/min.

1. therefore need a pen on the entrance side and a pen on the exit side, not to present a step too high to climb (inlet side) or to descend (outside side). the distance between the ends of the pens is about 460 mm; These pens should be stripped, with a 2.5 mm radius, for a thickness of 5 mm of the material (inox) of which the pen is made. the mat (or ribbon? mah?) should be 794mm wide and its development should be on 1100mm.

I am not very experienced in tapes (or is it said carpets?) of transport, and I find myself to draw one that, without special attention, they tell me will not stand on track.

If someone has experience, even some simple advice would help me a lot.

Thank you.

I describe the monster.

must transfer bulk food, from oven, rather friable, from a tape to another tape. both tapes have rollers of diameter large, 150 and 240 mm diameter. their centers are 500 mm. mat widths : upstream 850 mm and downstream 820 mm. that downstream has also containment edges. the minimum speed is 2 m/min and the maximum 4 m/min.

1. therefore need a pen on the entrance side and a pen on the exit side, not to present a step too high to climb (inlet side) or to descend (outside side). the distance between the ends of the pens is about 460 mm; These pens should be stripped, with a 2.5 mm radius, for a thickness of 5 mm of the material (inox) of which the pen is made. the mat (or ribbon? mah?) should be 794mm wide and its development should be on 1100mm.