lucadileta

Guest

I work with montech.com and also offer a support service to the designer. prices are competitive and quality is excellent. also possess compact solutions and engines in rollers.

has very small diameter rollers in the head but surely there is not much to invent. being postponed to the head you can approach the big rollers, but this is a normal technique used on small carpets.

has very small diameter rollers in the head but surely there is not much to invent. being postponed to the head you can approach the big rollers, but this is a normal technique used on small carpets.I am carefully rereading your post, trying not to propose different solutions but trying to optimize what you requested.Good morning to all colleagues.

I am not very experienced in tapes (or is it said carpets?) of transport, and I find myself to draw one that, without special attention, they tell me will not stand on track.

If someone has experience, even some simple advice would help me a lot.

Thank you.

I describe the monster.

must transfer bulk food, from oven, rather friable, from a tape to another tape. both tapes have rollers of diameter large, 150 and 240 mm diameter. their centers are 500 mm. mat widths : upstream 850 mm and downstream 820 mm. that downstream has also containment edges. the minimum speed is 2 m/min and the maximum 4 m/min.

1. therefore need a pen on the entrance side and a pen on the exit side, not to present a step too high to climb (inlet side) or to descend (outside side). the distance between the ends of the pens is about 460 mm; These pens should be stripped, with a 2.5 mm radius, for a thickness of 5 mm of the material (inox) of which the pen is made. the mat (or ribbon? mah?) should be 794mm wide and its development should be on 1100mm.

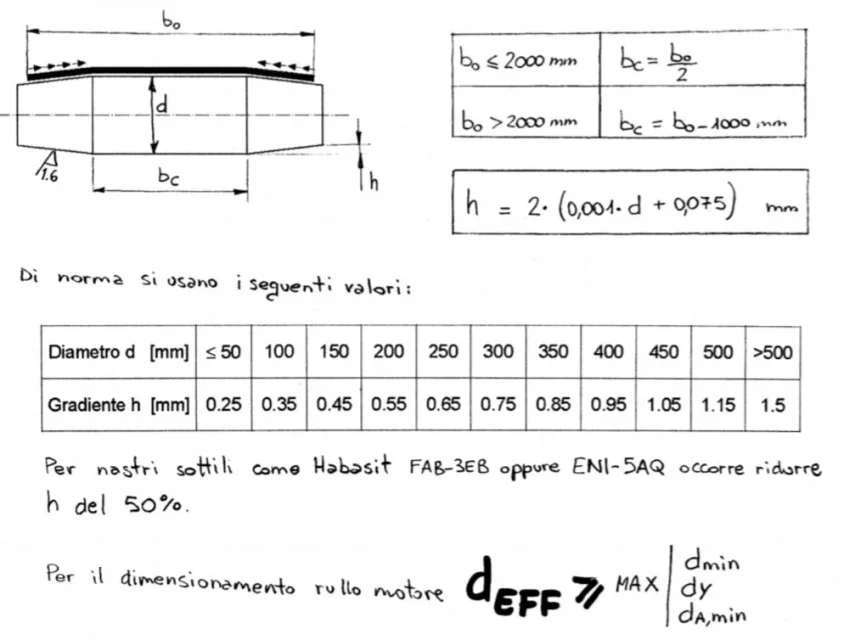

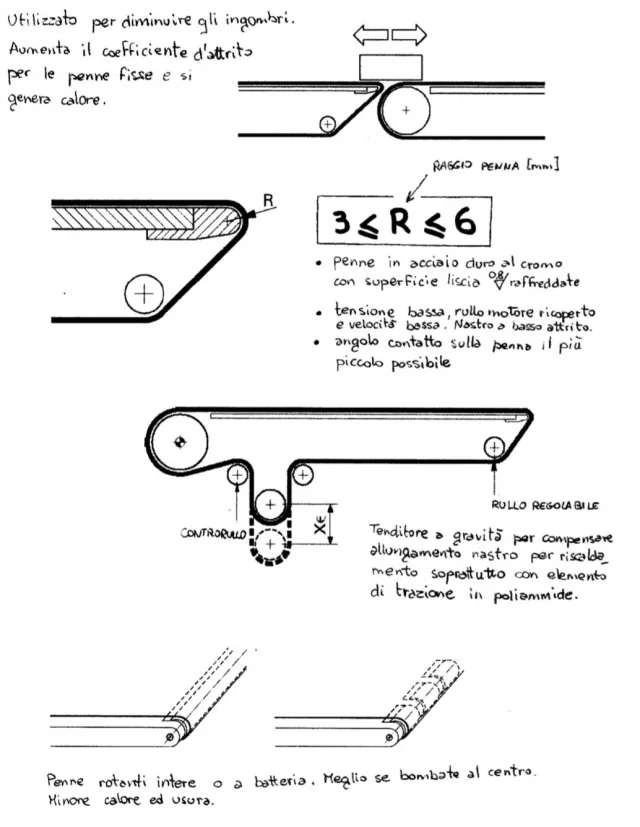

- the pen can not have radius 2.5 but something more, as attached, must be cooled, in rectified cementing material or with bombed rollers in the center

- the pen can not have radius 2.5 but something more, as attached, must be cooled, in rectified cementing material or with bombed rollers in the center - use little winding angle on the pens and so much on the motorized roller to give right grip force for friction

- use little winding angle on the pens and so much on the motorized roller to give right grip force for friction - often to make pens with non-stripping elements use ball bearings or needles or igus bronzines in plastic material (the most suitable)

- often to make pens with non-stripping elements use ball bearings or needles or igus bronzines in plastic material (the most suitable)an infallible way is a fife type guide,but beyond the donkey back rollers and blasphemies there are other ways to make tapes straight?:roflmao:

What is a fife guide? some kind of active tape tension control system?an infallible way is a fife type guide,

I saw a tape with a guide that corrected the parallelism of a continuous roller,

Obviously it worked perfectly.

I couldn't memorize because I couldn't dwell and the less I could photograph.

This system was very small, very compact, and operated on a food line.

chapeau!

a fife or emg system....that are two brands of well-known builders who make driving systems using different principles, which can be magnetic, laser, x-rays.What is a fife guide? some kind of active tape tension control system?

it is used for bottles the staging.I intend to deviate the flow of the transported material, I attach a scheme for clarity. although, perhaps it is unenforceable if the material is too friable

If it is the tree that breaks, I do not know the speed of rotation or the loads, but put a bronze (of those type igus or, I prefer, of those covered in ptfe) so the tree becomes bigger?the smooth tree I can't do it because as I said above I have to be with the radial encumbrance to about the size of the tree I attach a clearer design so that it can be understood better.

mine was a question to understand if it is correct to think that double bearing only does damage.

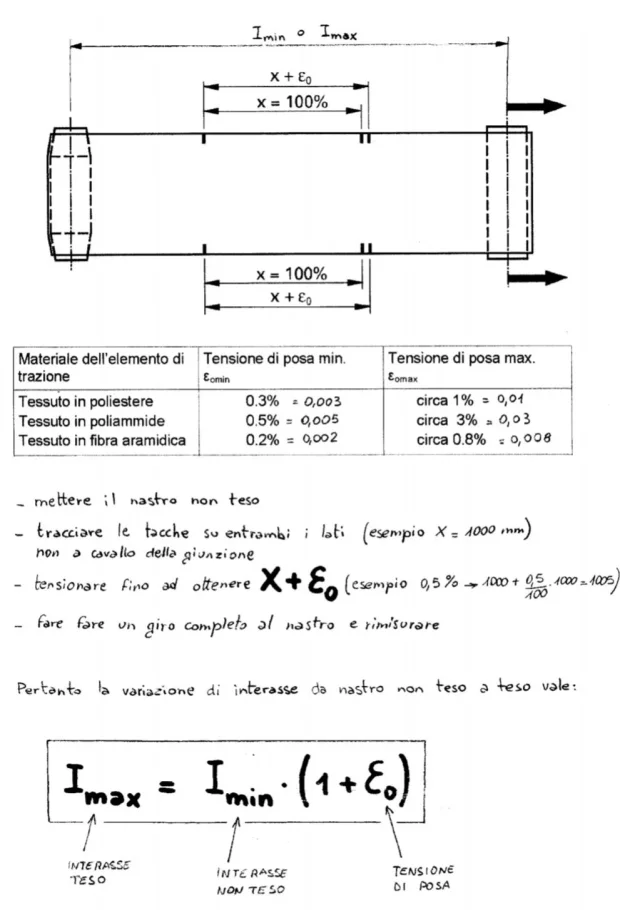

However to solve the problem I am increasing the diameter of the pen from ø25 to ø30 mm so as to have to pull in a reduced way the tape (which I repeat has certainly been strained too much by the customer), increased the section of the tree where there are the bearings (from ø10 to ø15) and put of the bigger bearings, moreover I am passed from a tree in butter (aisi 304) to one in duplex.

Meanwhile thanks to the spreadsheet I will obviously store. ....I forgot to enter the calculations,

ps teseo aisi 304 is a bit better than carpentry but mechanically cannot compete with a reclaimed or other