hi, the comparison between hazelnuts (commercial name) and nutella (commercial brand) with regard to me is definitely in favor of the first, with reference to what does not contain and what it contains, who was softly curious finds everything on the net. This is where I find my place: - but one account is to tell them and one account is to live them –

I press that I started using both sw and inv 9 years ago, sw I hate it though I have resumed using it currently in ut 2 years ago after a short but intense period

lasted 2 years during which I used inv +topinv + d&d qs.

9 years ago with inv was love at first sight, accomplice acad, when I can buy online courses mainly for inv in addition to looking for all sorts of tutorials, for curious sw almost daily on the net, formame ( can you mention?? ) provides excellent ideas.

I will try to be as objective as possible without neglecting my judgment that will necessarily be subjective. (ii) inv > inventor, sw solidworks )

rules: with inv you follow, with sw you and you adapt or better you interpret.....

as far as I'm concerned is a kind of free hand, it lets you do as much as you want, then somehow you put a piece on it, inv forces you to reason for how it was thought, you can make variations on the theme, but then if you make clever choices you pay the consequences.

the two modules are absolutely not - practically identical - they have similar functionality/instruments, some commands are equal but are not - practically identical - it is also for the fact that from inv you can pass/convert in sheet metal a component previously shaped as solid as with sw, but only with inv you can go directly into the sheet environment, choose the thickness and the material without then having to worry about setting or correcting the sheet parameters such as fold radius.

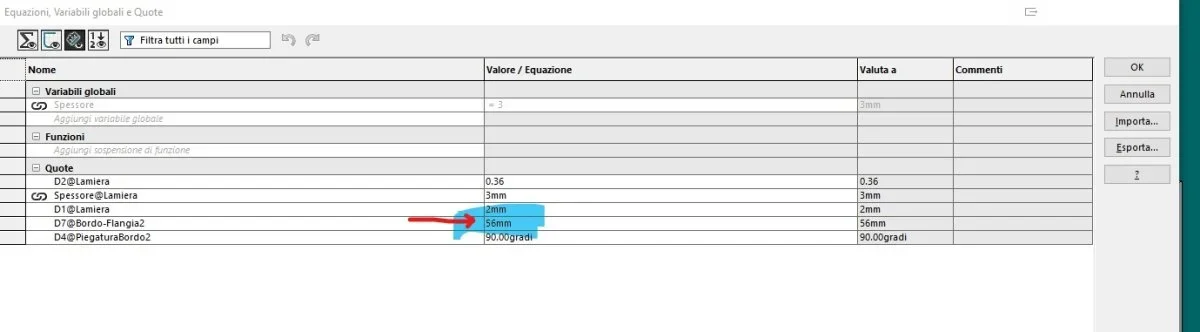

Of course, except for having compiled (extremely simple procedure in inv) or having a sheet archive (which can be downloaded without problems from the network ) complete in its parts, a customizable table easily as the commands are simple and intuitive in addition to the fact that they can adapt according to specific equations. as regards sw the gauge tables seems to be a military secret and being based on xls sheets I do not seem to be easily configurable missing the graphic part associated with the input of numerical values. but here I'm going to the end.

sw from solid you can switch to sheet metal, inv from solid you can switch to sheet metal, you can start immediately in sheet metal environment, already said, ( having immediately available the tools for sheet) from sheet metal you can convert or revert to solid......

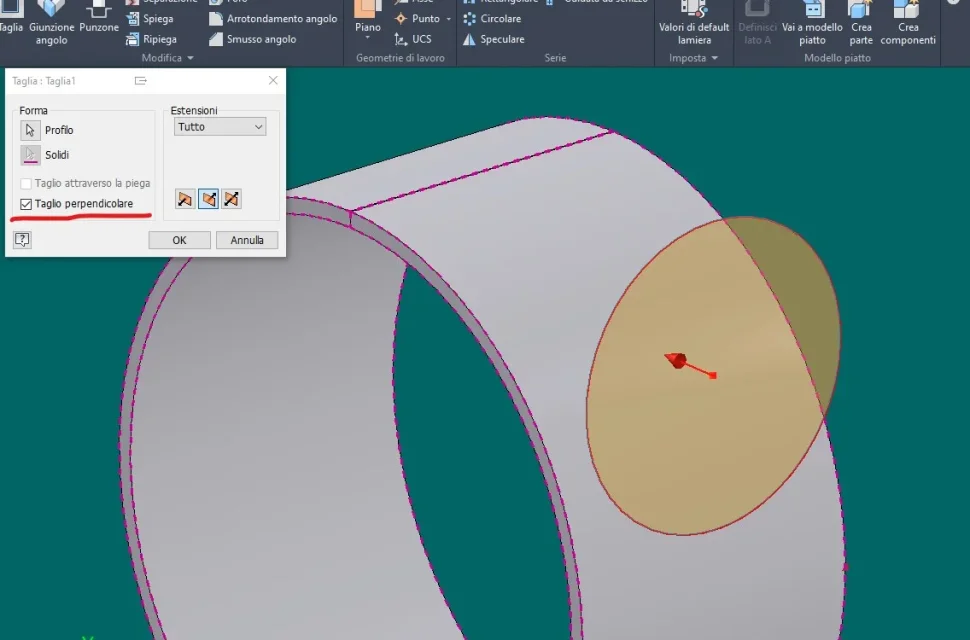

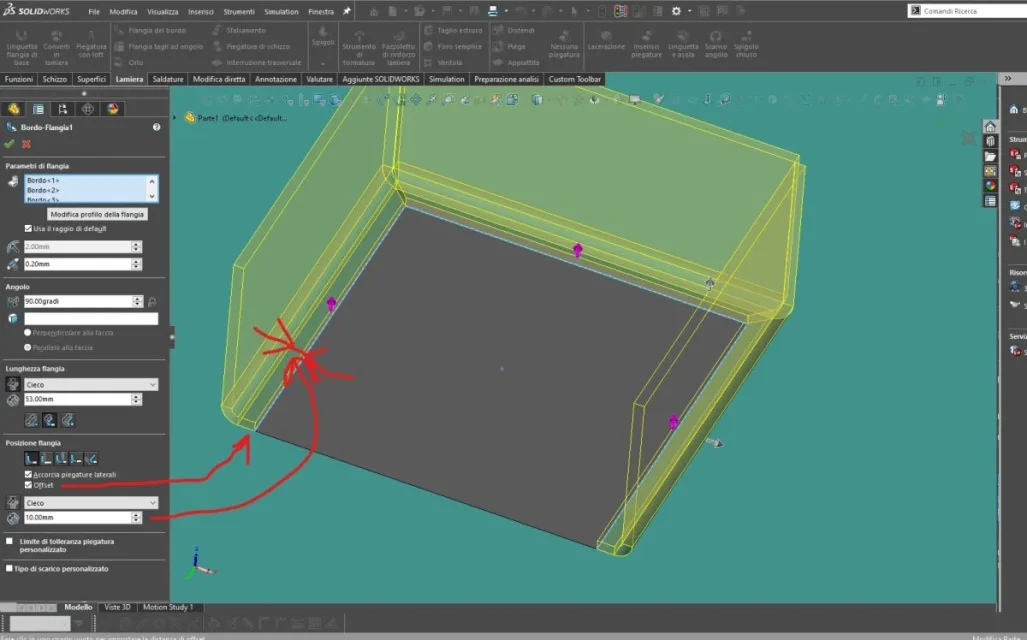

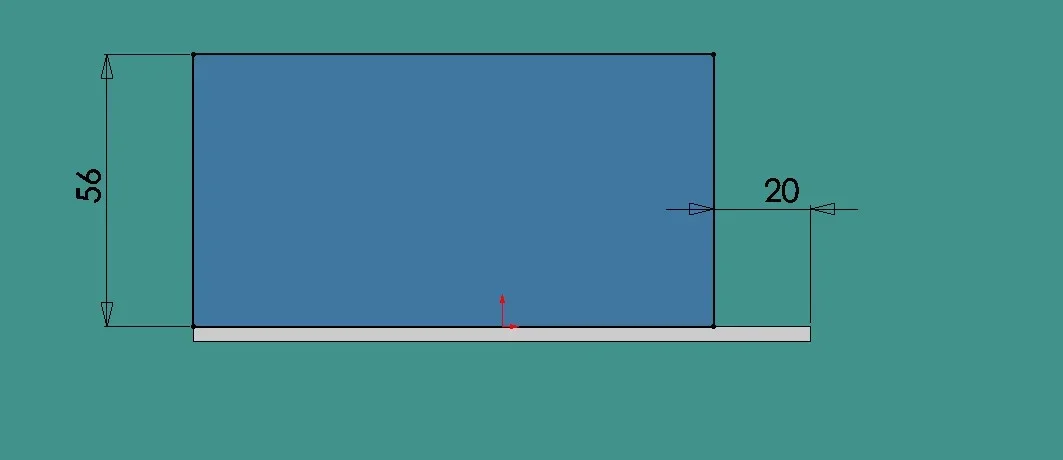

sw flange of the edge: Difficult linear modification, changing flange profile/form during creation in two steps assigning the shape of geometry as a sketch, beautiful but not always useful in the case of posthumous changes as geometric dimensions are not reported in the equations table.

if multiple flange, quini at the same time on multiple edges the change of shape must be made later for each edge.

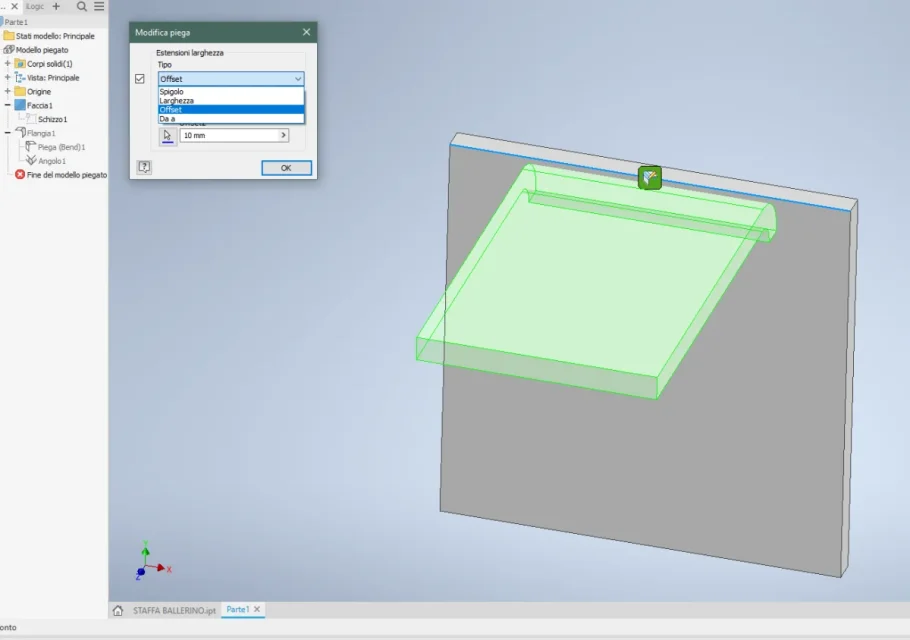

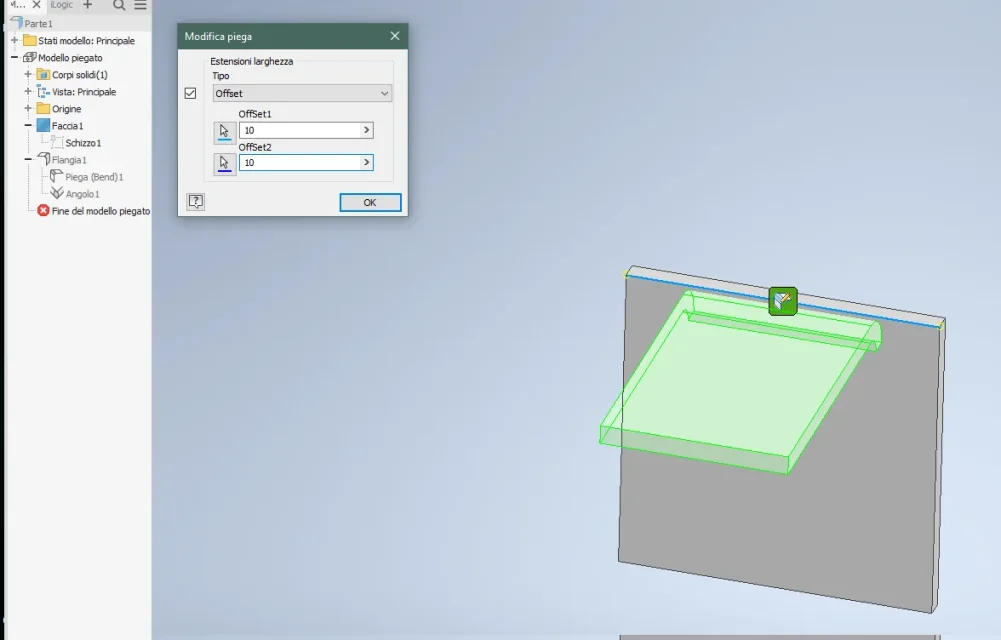

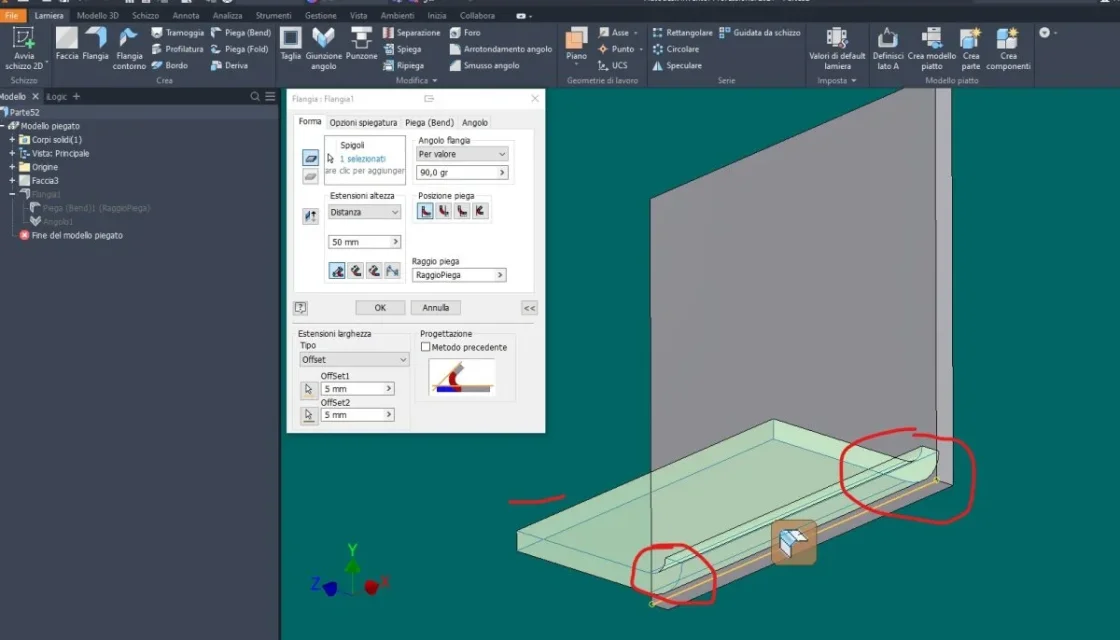

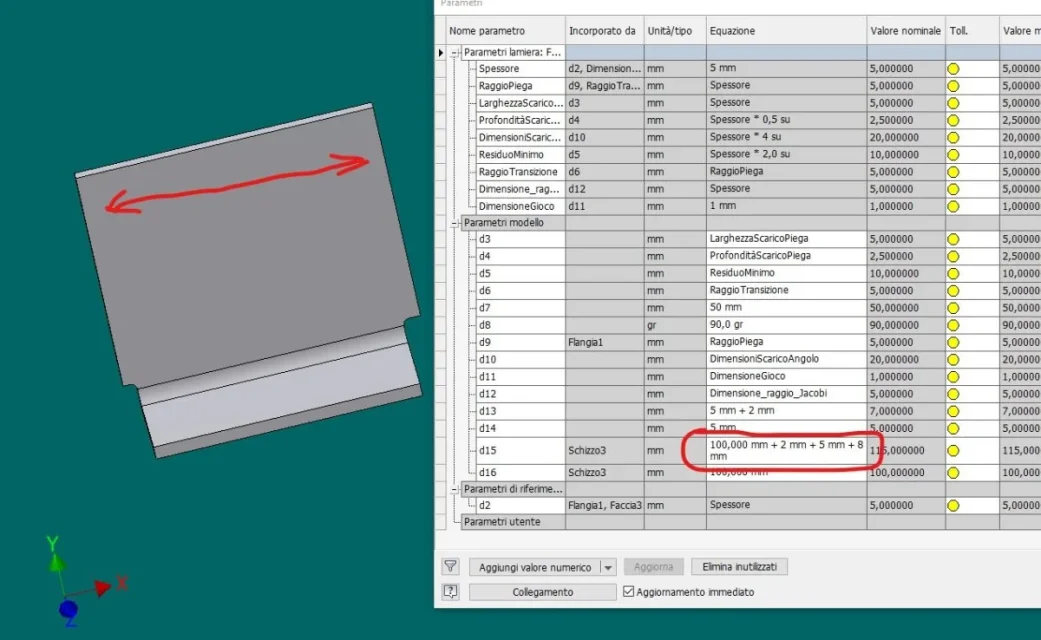

inv flange: Intuitive linear modification with real-time graphical interface, possibility for subsequent operations to maintain the parameters of the previous one, shape modification by applying sketch work.

in case of multiple flanges at the same time possibility of independent modification for each one without exiting the command.

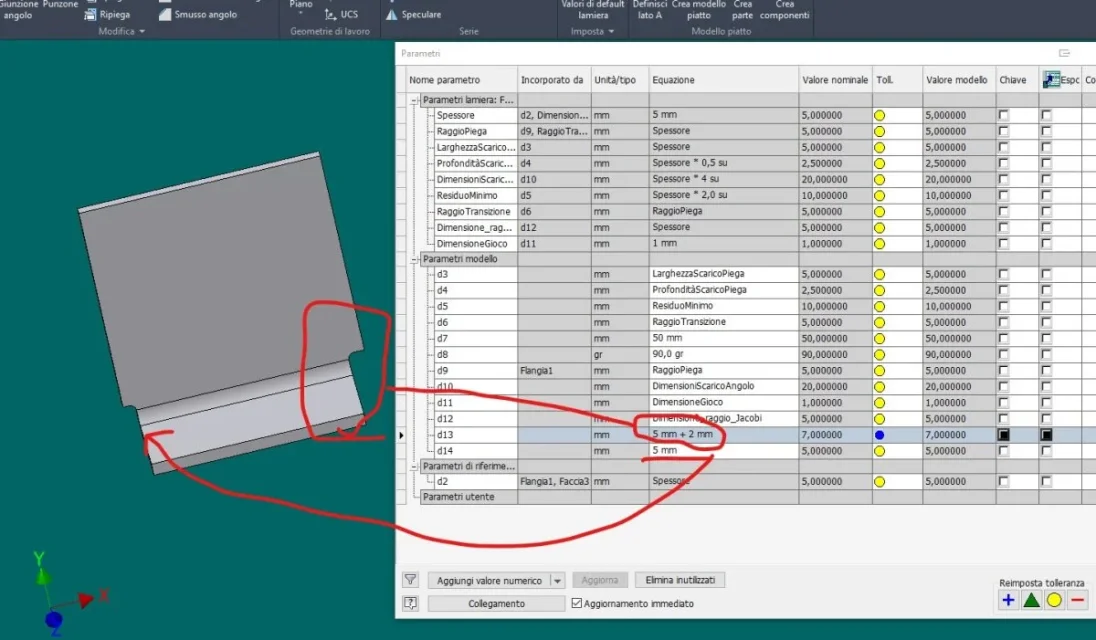

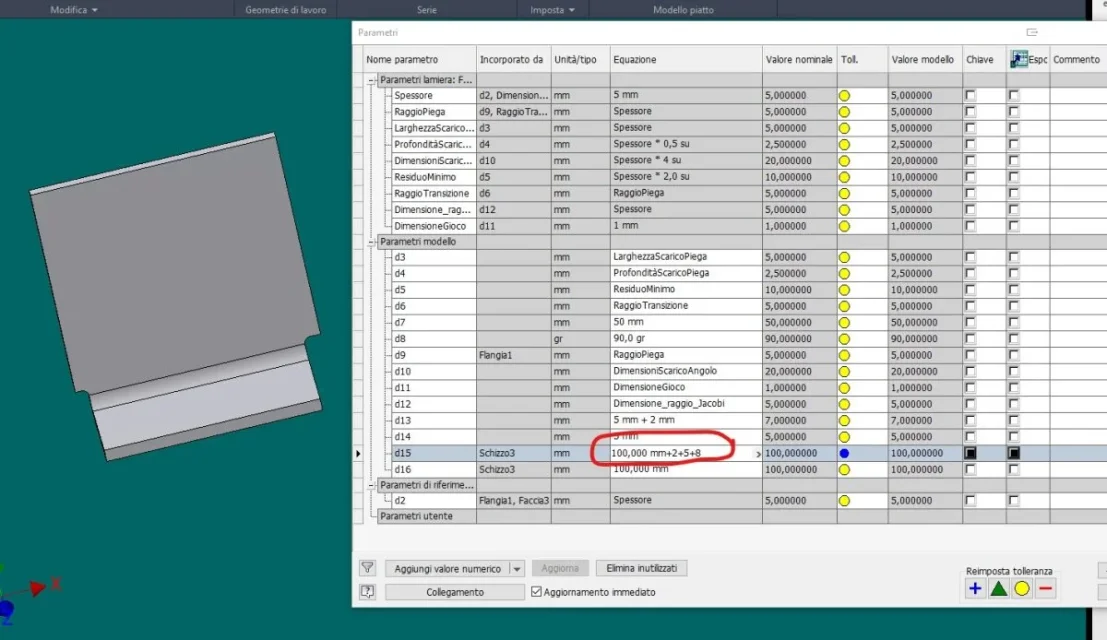

possibility to draw from list parameters, fx those that in sw are called equations for change both inv and sw

for both same position and length/extension strategy

sw edge = inv edge

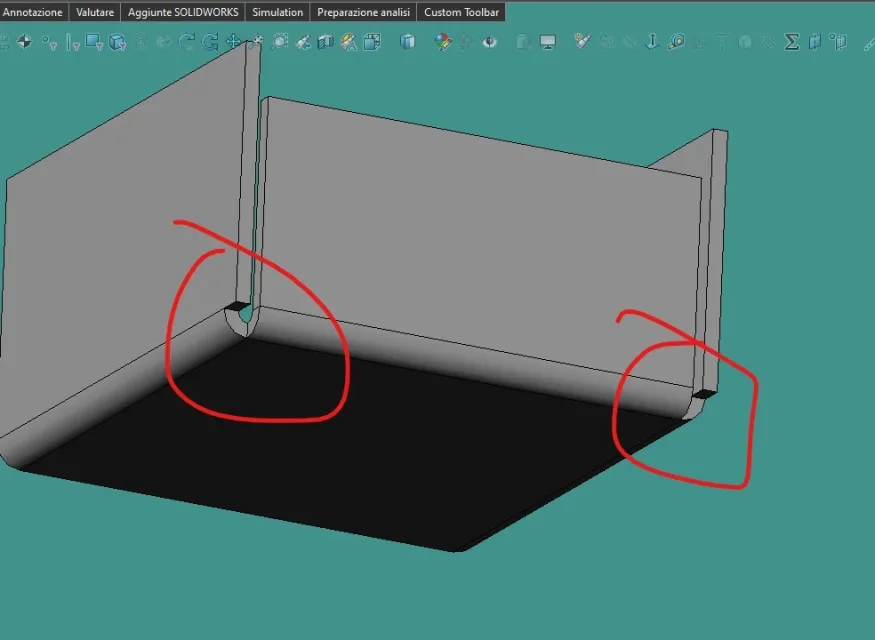

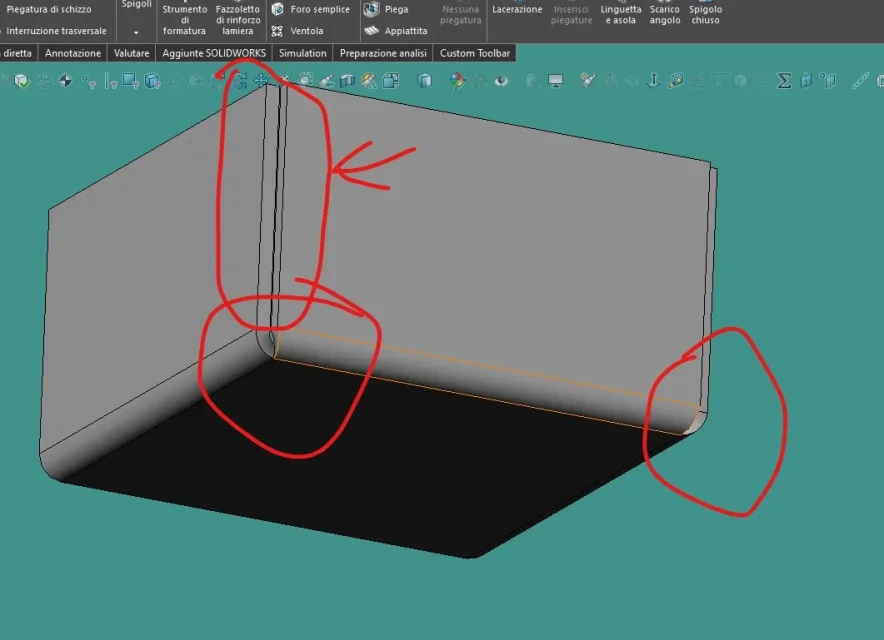

inv angle joint = sw edges > closed edge, present other processing

transversal break for diamonds, only quoteable graphics representation on the table, I also like it if you have to pay attention to the orientation in the table. I like it.

inv does not have it, but you can insert the cosmetic fold, I like more....

lamierainv fold (fold ): function that combines two separate faces. for me very useful.

inv fold ( fold ) : sw fold from sketch

sw staggering, interesting function that inv does not have: will it be useful??

sw reinforced handkerchief > inv nervatura but it is in model 3d

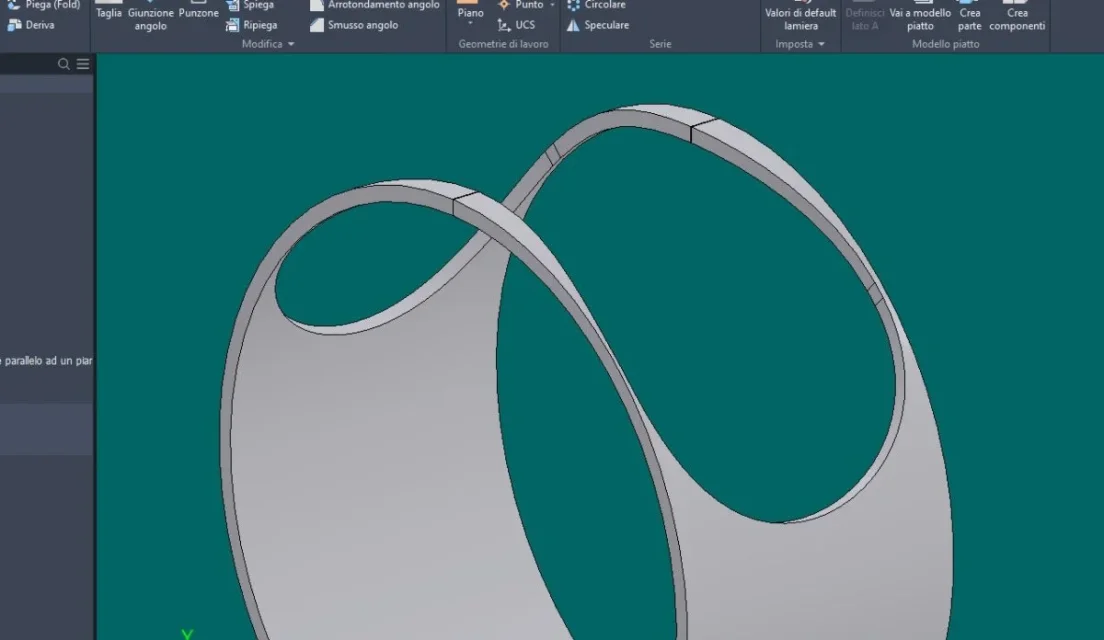

sw bending with loft > inv hopper + separation: is another story, much better than sw (see the tutorials on the net to make a hopper with sw and inv )

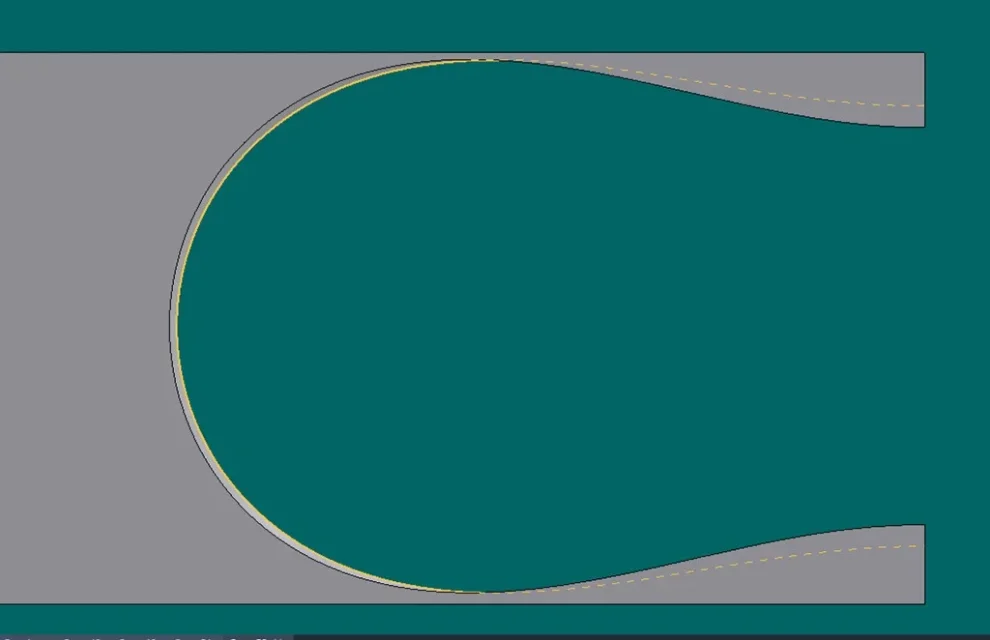

sw distendi + fold > inv explains + folds intuitive interface for both, I like more than inv

sw fan function, needs a sketch > inv punzone: all another world

archiveable punzone shapes for description and parameterizable to pleasure, for me super.

sw tongue and asola: great command, not easy to learn and manage with blocked or unlocked external references, acquired the technique will also like you.

sw toolbox vs inv design assistant, used together sheet/lamiera or solid/lamiera, solid/solid: another story, wonderful story.

the presence in addition to the 3 floors also of the relative axes are fundamental in in inv as well as the ability to enable multiple types of configurable geometric filters therefore recallable with text strings, fast keys or combination of keys that can be the same in the various working environments contrary to sw that manages only a letter or sequence of a letter + alt, shift or crtl that however should not be used in other environments.

but this exulates from the sheet metal modeling tools.

Concluding what to say? similar functions with different names, something extra on one or less on the other, it would be nice to have all those tools both in sw and inv, personally I prefer the inv sheet environment, it was also for the fact that its inv already has the sheet template.

then of course you adapt and it happens as when you learn to go cycling: you do not forget anymore and after two pedals with uncertain balance then you row straight.

the way of thinking is different, or must be, between the two and as already written:

- an account is to tell them and an account is to live them –

Thank you for the patient reading and apologize for the french.

Hi.