Vinz88

Guest

boys good morning to all, having now joined the forum I thank all for the many times that I have "usufruit" of the forum to solve small problems while not being recorded.

I write today why I would need more massive help

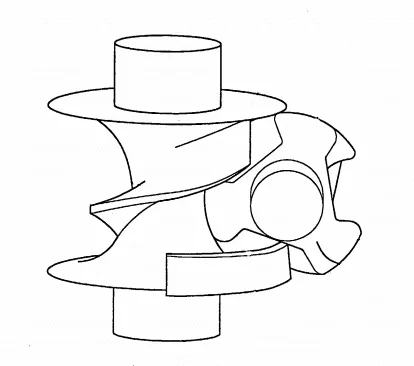

I have the need to dimension a seamless helical/vite gearbox with the following features and unfortunately I don't know where to start.

2:1 reduction ratio (around the screw must match 1/2 gear)

brass max 35mm gear

screw of a diameter that can insert a hexagon from 22 mm as a transmission axle and stiffening system.

I hope I can fix it, thank you all.

greetings

I write today why I would need more massive help

I have the need to dimension a seamless helical/vite gearbox with the following features and unfortunately I don't know where to start.

2:1 reduction ratio (around the screw must match 1/2 gear)

brass max 35mm gear

screw of a diameter that can insert a hexagon from 22 mm as a transmission axle and stiffening system.

I hope I can fix it, thank you all.

greetings