meccanicamg

Guest

for discourse heat treatment we are talking about surface tempering to induction 56/58hrc that also a c45 pre reclaimed, quality square meters iso 6336-5 (equival to agma grade 2), for a minimum depth of 0.7mm up to a maximum of 1.2mm, can reach.I am doubtful about the 6 w... 1111 n strength and 3 mm/s speed give a value of about half, but it should be evaluated the system's start and stop transients take into account forces and pairs of inertia.

However, it must also indicate hardness and depth.

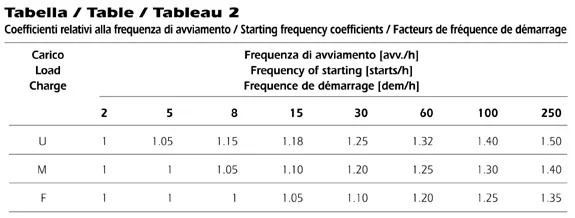

Of course you get half. in the excel sheet I used a factor then 1.5 and then I arrive almost double. Surely transients with accelerations will be decisive.