meccanicamg

Guest

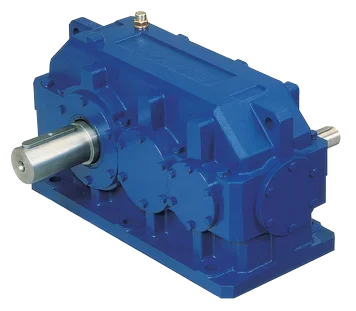

I did some evidence and on the single stage you don't understand much with the numbers coming out. in the reducer two stages instead if we use u=z2/z1..... numbers greater than 1 come out completely impossible relationships because you can not go even to 20 of relationship when you have to get to 100.

so in formulas it is used as u=z1/z2.... minor numbers of 1.

who then call the or u... let's forget.

so in formulas it is used as u=z1/z2.... minor numbers of 1.

who then call the or u... let's forget.