meccanicamg

Guest

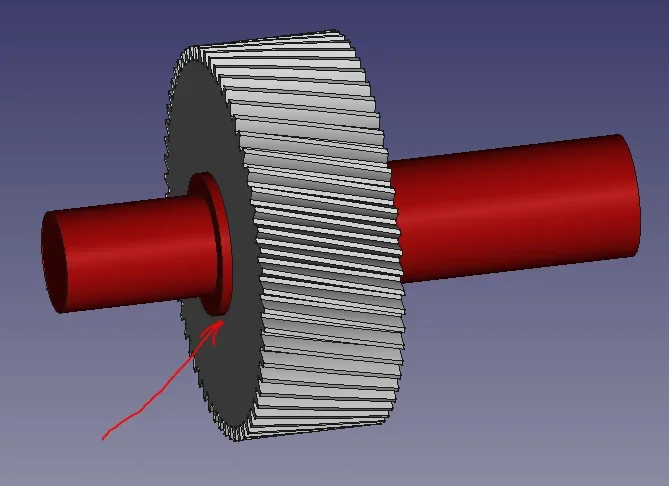

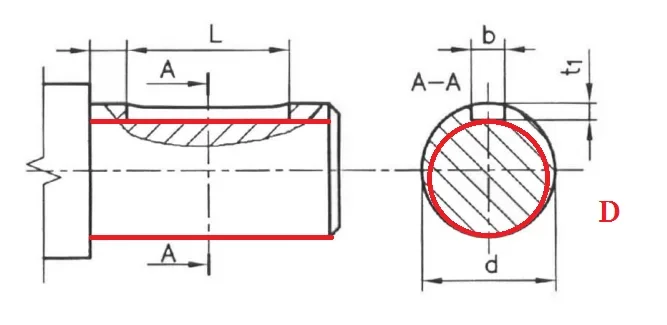

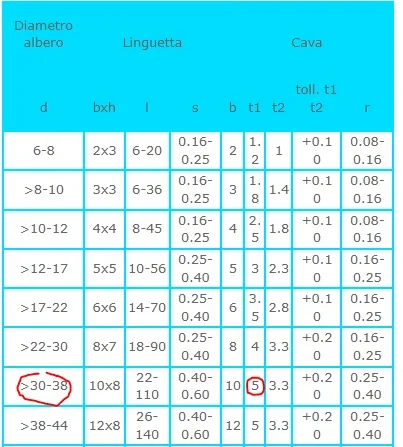

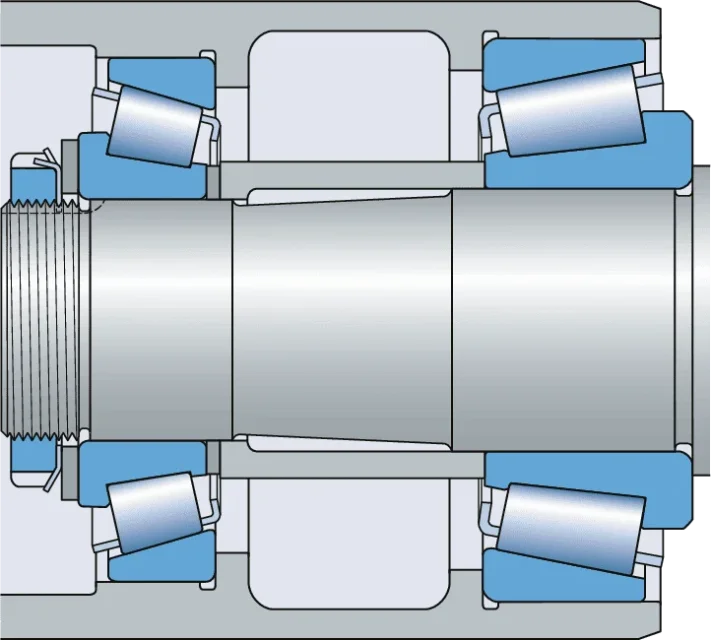

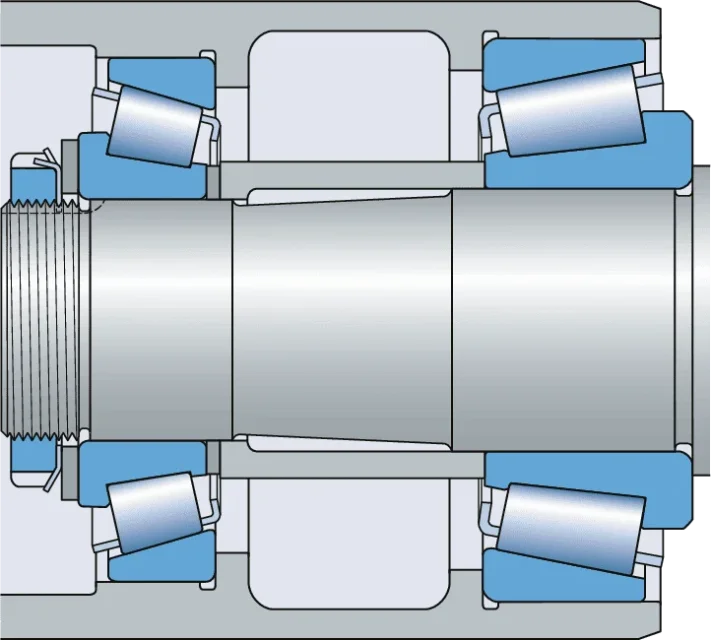

mounting to or hyperstatic two conical roller bearings are used to or from the axis. this system is more rigid and suitable than the precise application. as you see we have spacers that make the axial shaved preload and the wreath keeps to pack everything concerning the inner rings.

two conical roller bearings are used to or from the axis. this system is more rigid and suitable than the precise application. as you see we have spacers that make the axial shaved preload and the wreath keeps to pack everything concerning the inner rings.

this system adds a step and then an extra jump with its shouldering compared to the method described above (flapping).

then there are many other intermediate solutions that you explain also qui.

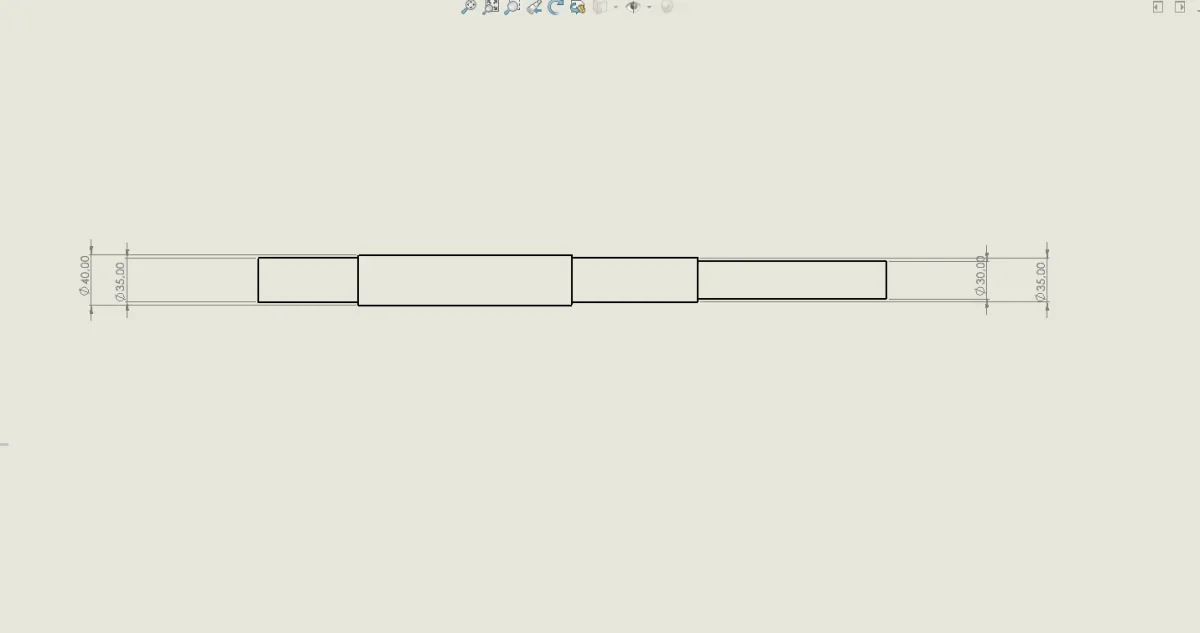

then there are very poor solutions, which are also made at an industrial level, where the step of the external shaft is eliminated, the diameter of the seal is raised and leaves all a single diameter including the bearing. you avoid as much as possible, you use some seegers and many spacers. However, it is necessary to be careful and, in any case, solutions adopted in the floating mode. However, they are solutions to save and optimize but it is necessary to proceed with caution and know well the behaviour of the load and where the reducer goes.

two conical roller bearings are used to or from the axis. this system is more rigid and suitable than the precise application. as you see we have spacers that make the axial shaved preload and the wreath keeps to pack everything concerning the inner rings.

two conical roller bearings are used to or from the axis. this system is more rigid and suitable than the precise application. as you see we have spacers that make the axial shaved preload and the wreath keeps to pack everything concerning the inner rings.this system adds a step and then an extra jump with its shouldering compared to the method described above (flapping).

then there are many other intermediate solutions that you explain also qui.

then there are very poor solutions, which are also made at an industrial level, where the step of the external shaft is eliminated, the diameter of the seal is raised and leaves all a single diameter including the bearing. you avoid as much as possible, you use some seegers and many spacers. However, it is necessary to be careful and, in any case, solutions adopted in the floating mode. However, they are solutions to save and optimize but it is necessary to proceed with caution and know well the behaviour of the load and where the reducer goes.