Zamparto

Guest

Bye to all,

I searched on the forum but found nothing, so I ask here.

for the examination of construction of machines I am carrying out a project of a double scissors lift from workshop for cars, but I met some hitch. First of all, I found that the most critical point for the piston is when the lift is practically closed, and right at this point I get forces that are more than 100 kn (about 11 tons) considering that I have to lift a mass of 1500 kg. with this force, however, the pin to which the piston is connected is really too large. So I was wondering if the order of magnitude of the piston force was consistent with this type of application or I made some mistake in the equation system from which this force turns out.

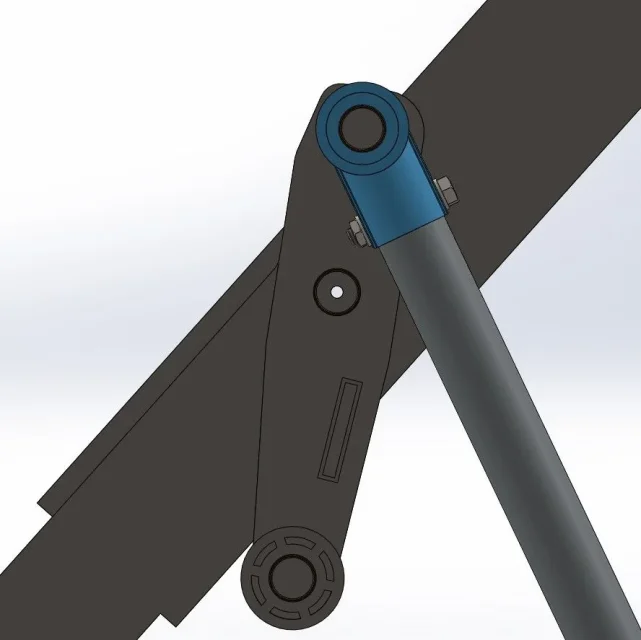

I also attach photos of the lifter and how I scehmatized everything.

Thank you in advance!

I searched on the forum but found nothing, so I ask here.

for the examination of construction of machines I am carrying out a project of a double scissors lift from workshop for cars, but I met some hitch. First of all, I found that the most critical point for the piston is when the lift is practically closed, and right at this point I get forces that are more than 100 kn (about 11 tons) considering that I have to lift a mass of 1500 kg. with this force, however, the pin to which the piston is connected is really too large. So I was wondering if the order of magnitude of the piston force was consistent with this type of application or I made some mistake in the equation system from which this force turns out.

I also attach photos of the lifter and how I scehmatized everything.

Thank you in advance!