sampom

Guest

Reggio,But here I'm not here yet...

Where's the trick? ? ?

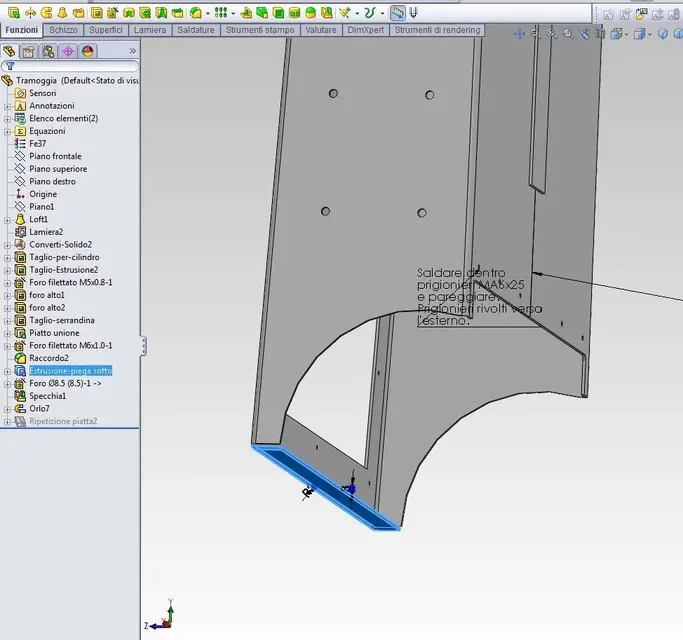

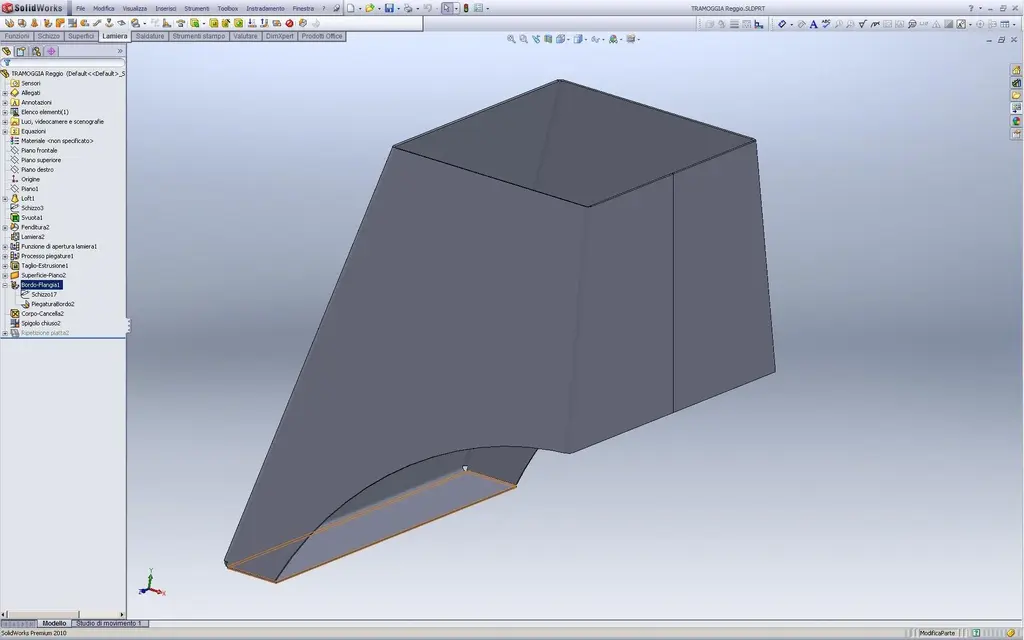

... I attach my proof to which the bending does not add.. .

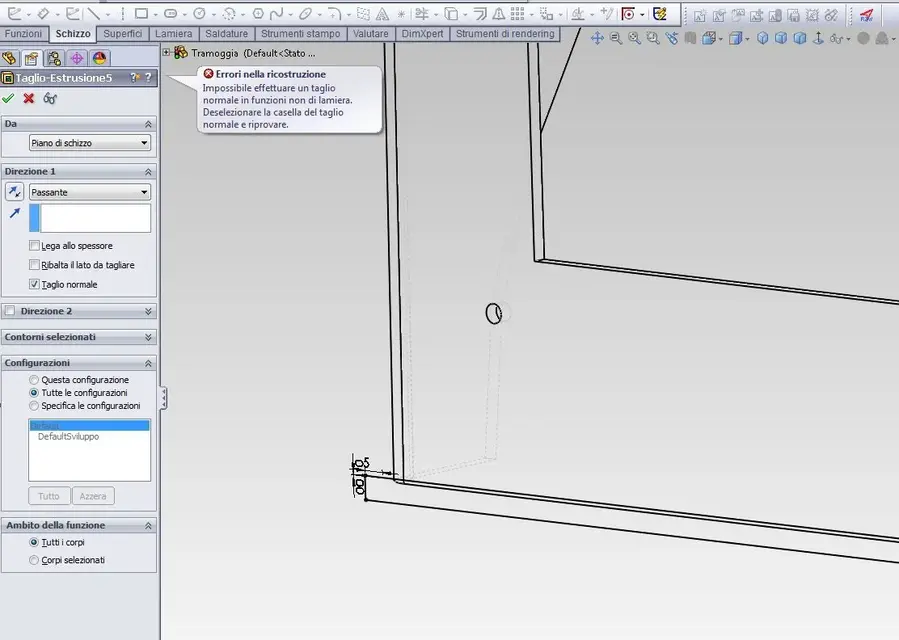

... in the other I also tried to cut off the slice but it does not work and in fact cutting as I show it should not work because it alters the thickness sheet ...

... explain to me ... with simple words and an example file if possible... :36_1_31:

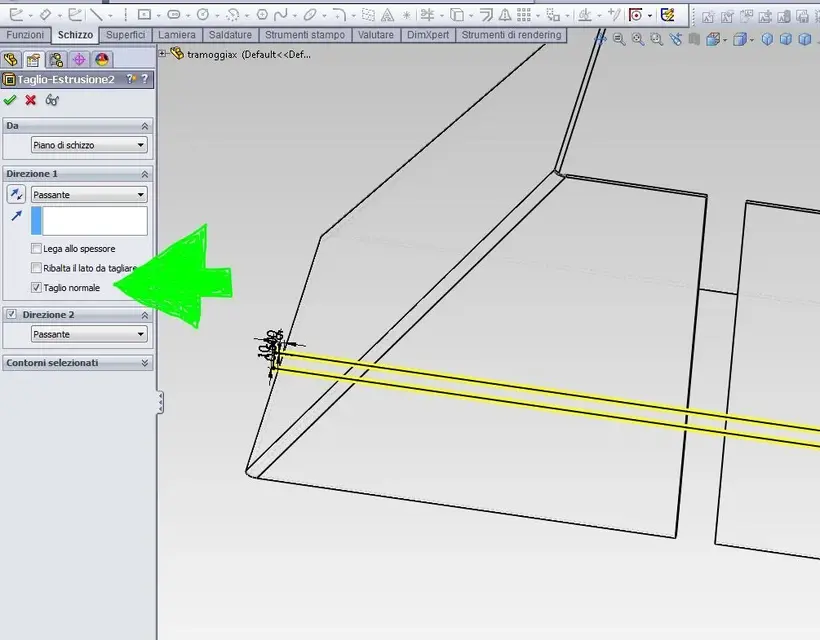

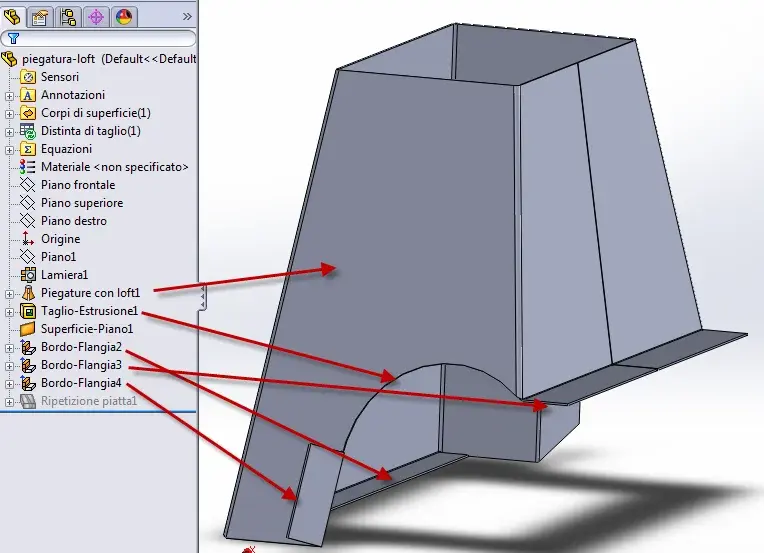

the cut you have to do normalWith the sheet always reminds him to flag the option.

then, as mike said, the solid converts often gives problems (unexplained...). you can do it in the same way using the "old" feature of insert folds and so generally works and you don't even need the normal cut anymore (there's the extra pass that you must first empty.. but you did the same.

greetings

Marco:smile: