You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

gerod

Guest

but how is deformed?

gtsolid

Guest

is that deformed, I tried also isolating the body (via roller, engines, etc....)but how is deformed?

the solid of the body is composed of a multitude of bodies, to which I also tried to merge them through the function "abbina", but nothing

Stan9411

Guest

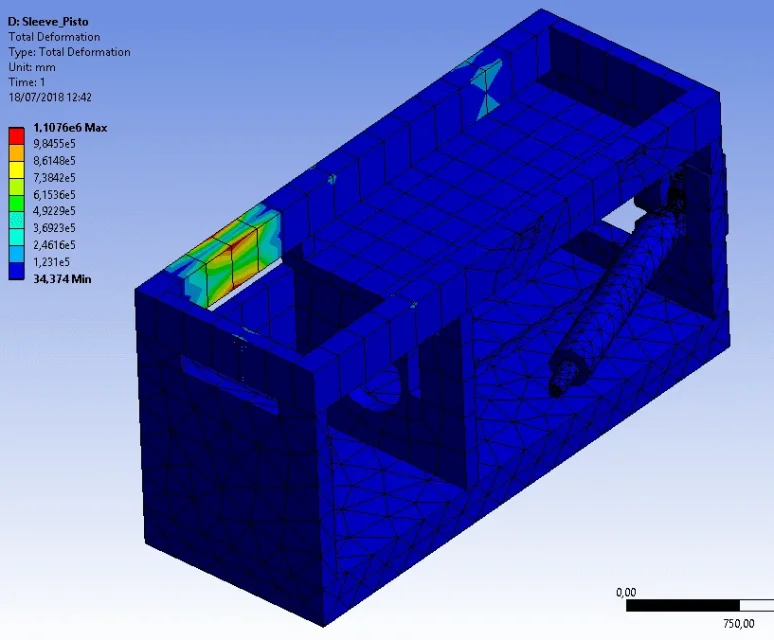

apart from that mesh is not tolerable (and already this can bring errors of convergence and approximation of the result ) but then it is not possible that the minimum shift is 34 mm if the system is at least isstatic!!!!! there is a clear error in the constraints, the global ones and most likely the local ones (between one component and the other) that in ansys are always a beautiful bitch.

to make us understand better you should show us the display of loads and constraints.

in any case improves mesh and resell constraints.

to make us understand better you should show us the display of loads and constraints.

in any case improves mesh and resell constraints.

gerod

Guest

[

I mean see how it deforms to the original. however the minimum will be 0, not 34 mmis that deformed, I tried also isolating the body (via roller, engines, etc....)

the solid of the body is composed of a multitude of bodies, to which I also tried to merge them through the function "abbina", but nothing

gtsolid

Guest

I found 2 errors:

- some characteristics of the material (granite) had not been transposed: they had the bar above the name of the property

- a component wasn't digested, it seems there was some game.

This last point has not been resolved: It seems that at least another element is not properly bound. I guess he's suspended in half the air. Is there a way to understand it from ansys? or piece per piece (they are hundreds) do I have to see them from solidworks?

- some characteristics of the material (granite) had not been transposed: they had the bar above the name of the property

- a component wasn't digested, it seems there was some game.

This last point has not been resolved: It seems that at least another element is not properly bound. I guess he's suspended in half the air. Is there a way to understand it from ansys? or piece per piece (they are hundreds) do I have to see them from solidworks?

meccanicamg

Guest

If you're doing a multibody analysis is one thing. but I ask myself, why don't you use solidworks with its beautiful static symulation module, do mesh not congruent and see what comes out? clearly you have to simplify that thing there because if you have to study the frame you have to remove everything else.

What do you mean you didn't digest?

with solidworks there can be interference, too complex geometries compared to mesh and similar things.

It also happens with solidworks, if you have a carpentry as a multibody part and the plates do not touch and apply loads you will see the plates flying in a destroyed way. so many times it is necessary to retouch the model only for the fem by adding a physical welding (maybe an extrusion) or change the contact geometry and cutting of the sheets.

What do you mean you didn't digest?

with solidworks there can be interference, too complex geometries compared to mesh and similar things.

It also happens with solidworks, if you have a carpentry as a multibody part and the plates do not touch and apply loads you will see the plates flying in a destroyed way. so many times it is necessary to retouch the model only for the fem by adding a physical welding (maybe an extrusion) or change the contact geometry and cutting of the sheets.

gtsolid

Guest

He couldn't meshare his body, he was a red mesh.What do you mean you didn't digest?

for suspended parts in half air then I will look solidworks, thanks to all

gerod

Guest

how does a body stay in half air?

try to see the deformed with high scale factor and you will see where the untied body is

try to see the deformed with high scale factor and you will see where the untied body is

gtsolid

Guest

Can you explain this to me?apart from that mesh is not tolerable (and already this can lead to errors of convergence and approximation of the result )

Stan9411

Guest

typically the precision of the solution increases to the decrease of the element size. below a certain threshold, the solution converges to an asymptote and continue to decrease the size becomes useless. These are basic things. a mesh so wide, even a single element on the wall affected by the analysis, is not appropriate, especially if you expect bending phenomena.

gtsolid

Guest

Is there a way to show the deformed of what was calculated until then? I can't find the body not in contact

gerod

Guest

What version of ansys use?Is there a way to show the deformed of what was calculated until then? I can't find the body not in contact

you can see results with scale factor. then you can also see the original solid in transparency, even in wireframe.

try first to make a calculation by entering a convergence criterion!

gtsolid

Guest

I use r16.

I have no access to the deformed (and therefore to the convergence criteria) because currently I have the error from here I assume that, being the mesh already dense, there must be something not properly bound, that I cannot find.

from here I assume that, being the mesh already dense, there must be something not properly bound, that I cannot find.

it would be nice to know what knot/element was found this excessive deformed, and to what body belongs

I have no access to the deformed (and therefore to the convergence criteria) because currently I have the error

from here I assume that, being the mesh already dense, there must be something not properly bound, that I cannot find.

from here I assume that, being the mesh already dense, there must be something not properly bound, that I cannot find.it would be nice to know what knot/element was found this excessive deformed, and to what body belongs

gerod

Guest

I'll do everything from scratch.

gtsolid

Guest

Yeah, it's the best thing. Thank you all!

by curiosity: how do you model the bearings? do you have best practices in this regard?

by curiosity: how do you model the bearings? do you have best practices in this regard?

gerod

Guest

never modeled for cases I met.

gtsolid

Guest

therefore create revolutions on the model only. I would like to thank the rapporteur for his excellent report.

Stan9411

Guest

In principle, they don't model... what do you need?

meccanicamg

Guest

for a fem the bearings do not model. use hinge or cart constraints, 3d constraints, bearing bond if you use solidworks symulation.

I think you're setting your model wrong. If you claim to make a fem with a frame with mounted a roller with or bearings and other mechanics I would say you have already mistaken thought.

Only one mechanical element at a time should be studied unless the elements are similar and homogeneous.

I think you're setting your model wrong. If you claim to make a fem with a frame with mounted a roller with or bearings and other mechanics I would say you have already mistaken thought.

Only one mechanical element at a time should be studied unless the elements are similar and homogeneous.