This time I printed it so... even if it sucks... and I marked you the corrections:biggrin:

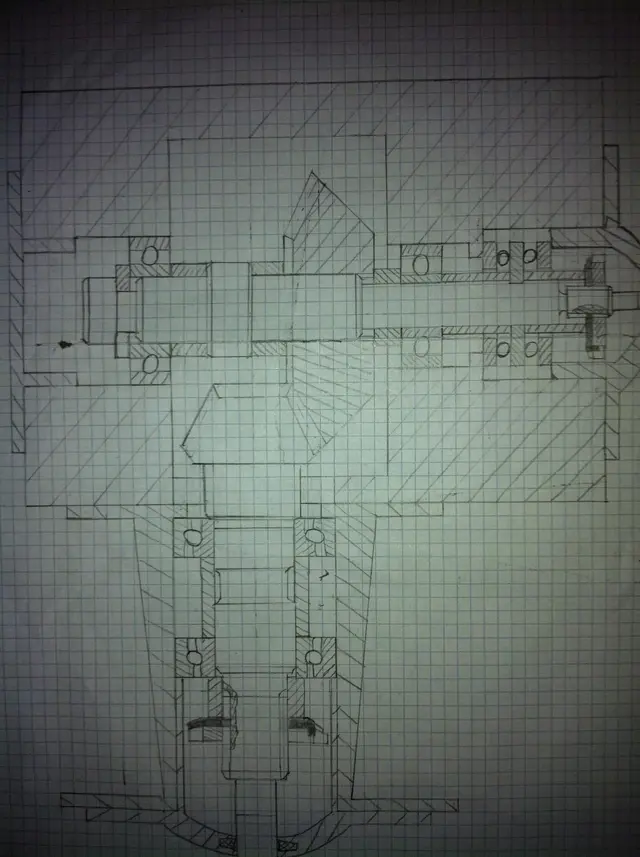

1) then for d>d: but the tree decreases it from above do not need to let go from there?! and then if I make the hole of the bigger case of the wheel, what do I put to block the oblique externally?

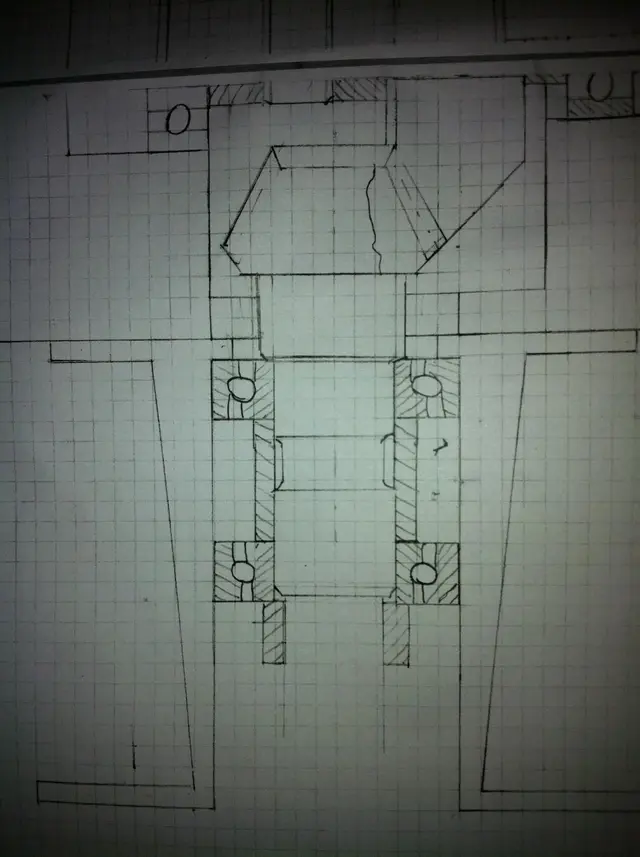

2) those in black are leafable

3) 2 wreaths for registration, the prof if not mistaken said 2 wreaths or 1 wreath and the folded plate.

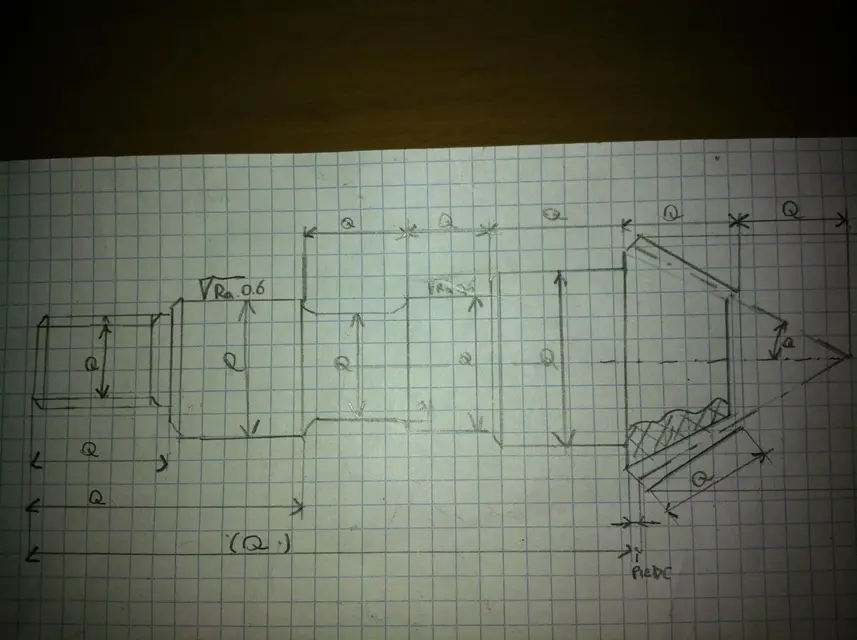

4)the question mark indicating the input shaft: there is the end of the tree with the cap, oils and rectification.

5)is the case sampled?

6)"the holes for what?" are holes that serve to close the other half of the case

7)because not the spacer; Did the prof tell me that I have to lock the inner ring and the outer ring remains free. Give me a logical explanation? ; and then I was wrong after the ball cux lacks the elastic ring that blocks the inside of the cux and then the end of the tree.

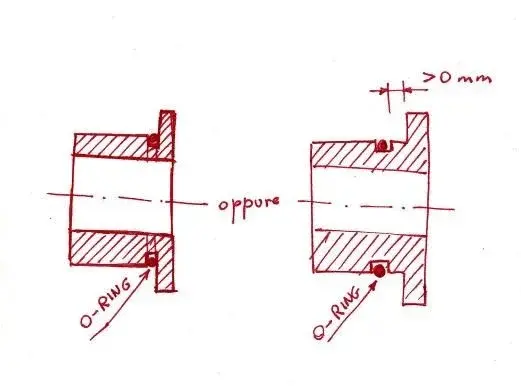

8)The triangles with the center point are the seals, tell me how they draw?

9) Thank you for your patience

10) you're too good!!