- Home

- Forums

- mechanical engineering

- creo parametric (ex pro/e)

- creo parametric - modeling of parts and sheet

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

lollone

Guest

I didn't really understand what your need is!

do you have family with the sheet form?

do you have family with the sheet form?

giuglioconiglio

Guest

No, I don't. see where the edge of the sheet is thinned? there I have to bend the whole of 90°

maxopus

Guest

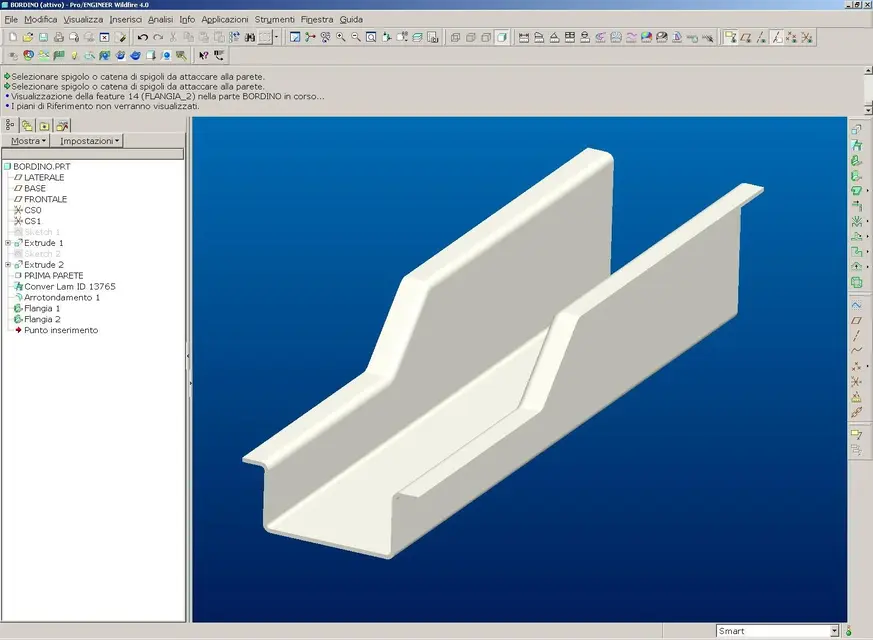

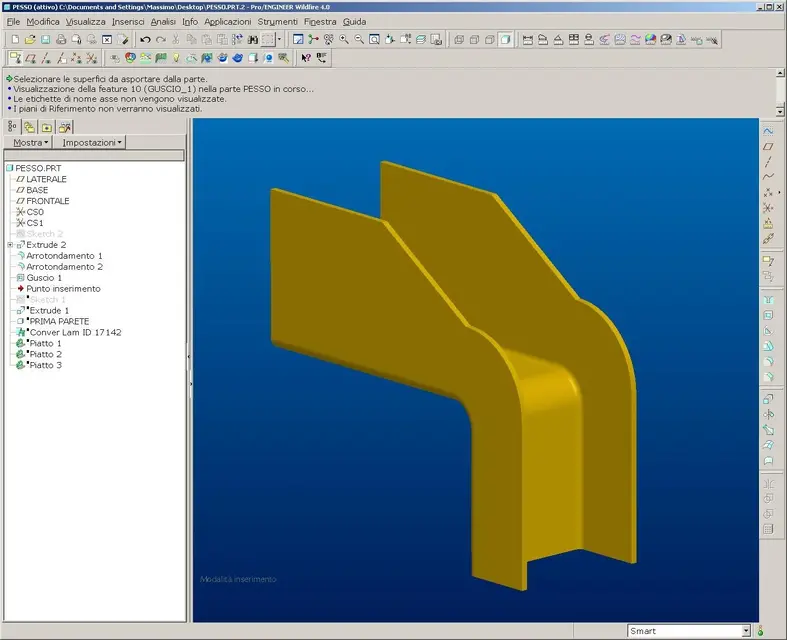

as from image?No, I don't. see where the edge of the sheet is thinned? there I have to bend the whole of 90°

you need to round the edges alive to make the flap continuous.

But keep in mind that a piece of this stuff is not done.

Attachments

giuglioconiglio

Guest

Hell, no, I didn't mean that way! I'm sorry I made you work for nothing. I try to explain myself better: you have folded parallel to the longitudinal axis of the piece, instead I have to fold transversally to the longitudinal axis. in practice at some point the side edges lower, when the lowering ends there I have to bend. I did a png edict to show you where I should bend.

hello and thanks gc

hello and thanks gc

Attachments

lollone

Guest

Maybe you have to do the dumps?

giuglioconiglio

Guest

Yes, I certainly have to make some discharges otherwise the sheet overlaps, but I do not know if the program does it itself and if yes as.

maxopus

Guest

giuglioconiglio

Guest

No, I don't have to bend the wings but all the terminal part!

maxopus

Guest

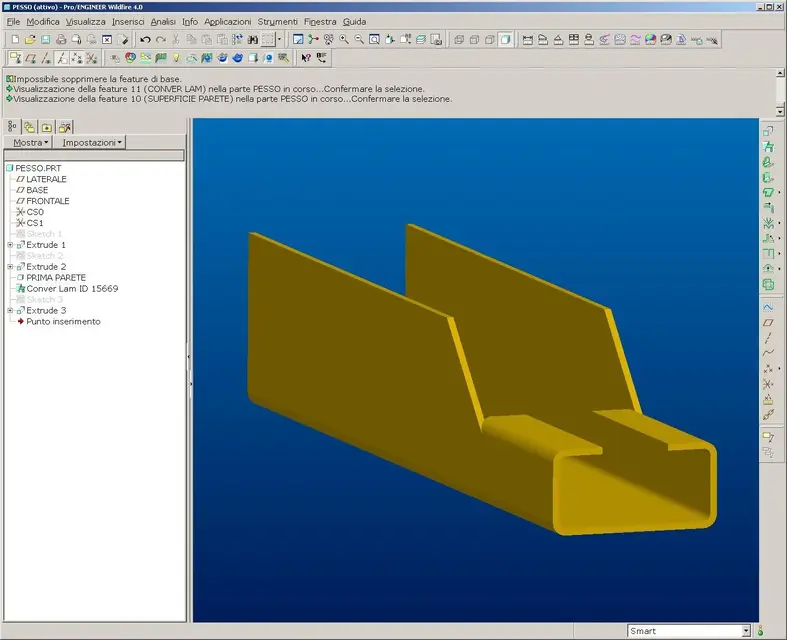

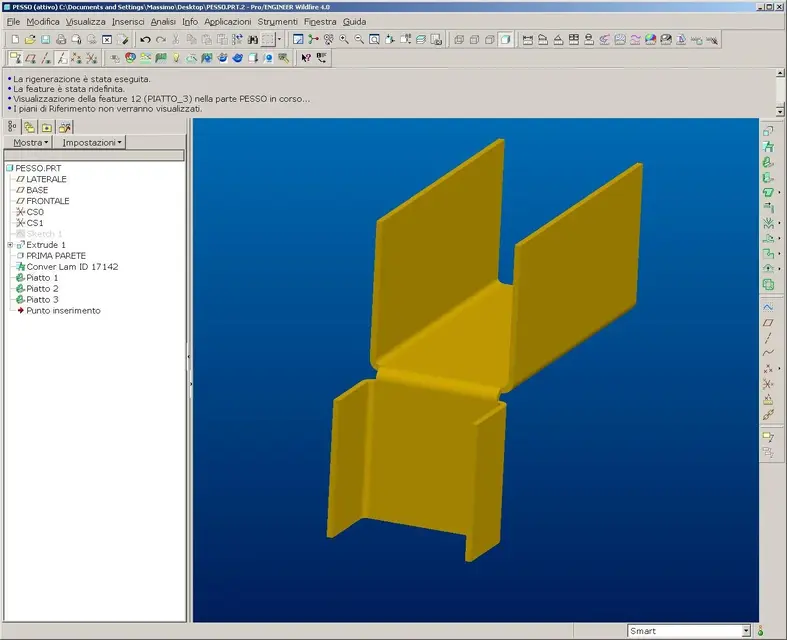

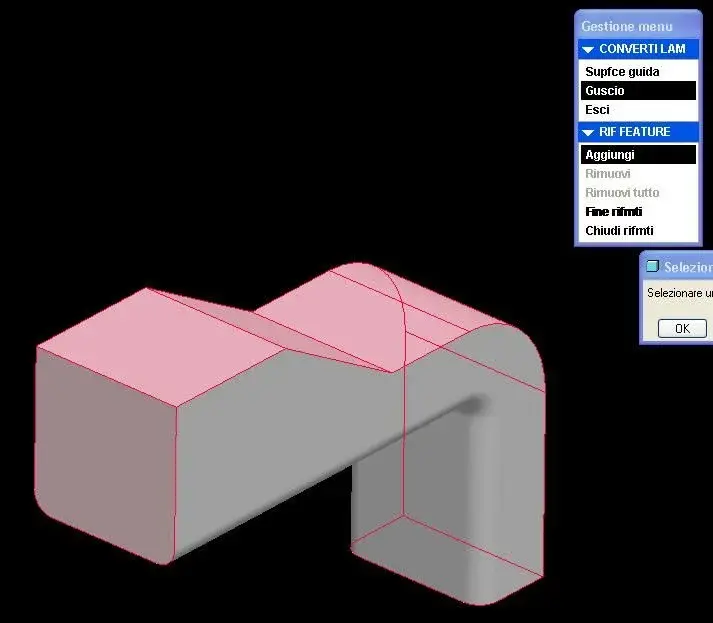

You can't do it as you say.No, I don't have to bend the wings but all the terminal part!

the most you can get is what you see in the attachment and the missing piece you should weld it.... unless we talk about funnel molds but, sheet metal is not applicable to that area.

Attachments

maxopus

Guest

giuglioconiglio

Guest

Okay, thanks.

maxopus

Guest

cletus

Guest

giuglioconiglio

Guest

Okay, a thousand grazies!