Pierpat

Guest

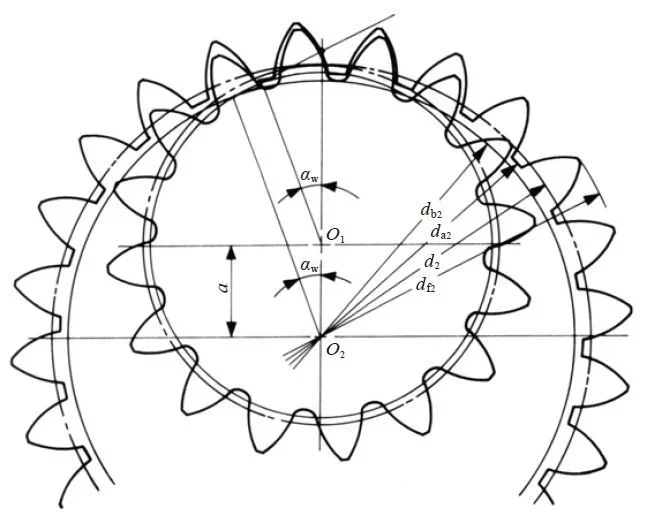

Good morning, meet me. I am a young designer of foundry equipment (models, anime molds, etc.) with a 2-year experience in the role. I was asked by a friend to draw a gear (of which I attach photos) of what I think is a drill or something.

not having experience on this type of mechanical components, my difficulty is to properly dimensional the teeth of the gear having at disposal are a caliber and failing to find a reference norm for the standard size.

I hope someone can give me a tip. thank you in advance to those who will have the time to answer.

not having experience on this type of mechanical components, my difficulty is to properly dimensional the teeth of the gear having at disposal are a caliber and failing to find a reference norm for the standard size.

I hope someone can give me a tip. thank you in advance to those who will have the time to answer.

Attachments

-

IMG-20210806-WA0004.webp93.2 KB · Views: 22

IMG-20210806-WA0004.webp93.2 KB · Views: 22 -

IMG-20210806-WA0005.webp91.6 KB · Views: 22

IMG-20210806-WA0005.webp91.6 KB · Views: 22 -

IMG-20210806-WA0006.webp92.2 KB · Views: 18

IMG-20210806-WA0006.webp92.2 KB · Views: 18 -

IMG-20210806-WA0008.webp102.7 KB · Views: 18

IMG-20210806-WA0008.webp102.7 KB · Views: 18 -

IMG-20210806-WA0007.webp88.6 KB · Views: 18

IMG-20210806-WA0007.webp88.6 KB · Views: 18 -

IMG-20210806-WA0003.webp153.9 KB · Views: 20

IMG-20210806-WA0003.webp153.9 KB · Views: 20 -

IMG-20210806-WA0001.webp88.8 KB · Views: 18

IMG-20210806-WA0001.webp88.8 KB · Views: 18 -

IMG-20210806-WA0000.webp80.1 KB · Views: 17

IMG-20210806-WA0000.webp80.1 KB · Views: 17 -

IMG-20210806-WA0002.webp96.5 KB · Views: 29

IMG-20210806-WA0002.webp96.5 KB · Views: 29