max&cad

Guest

Good morning to all,

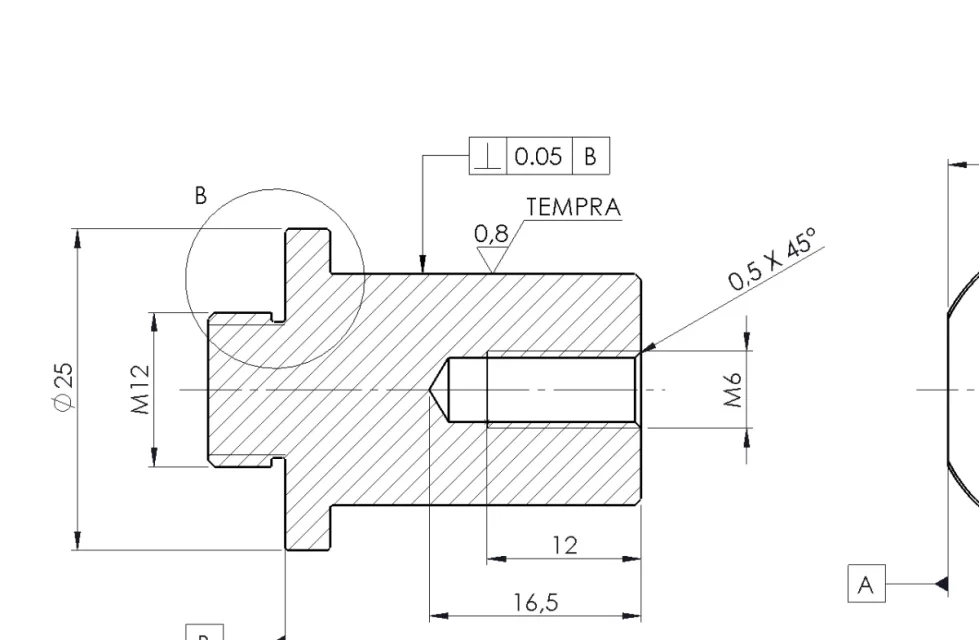

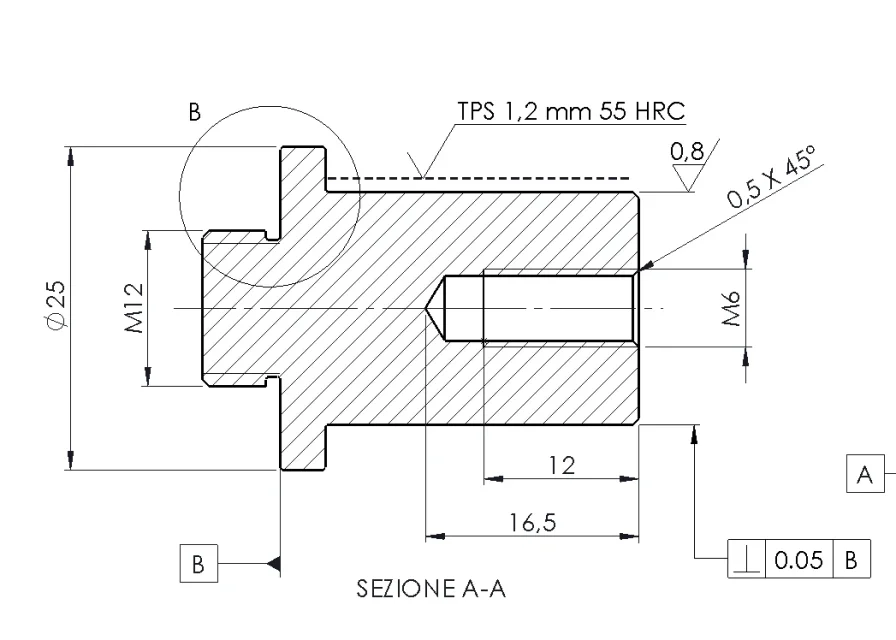

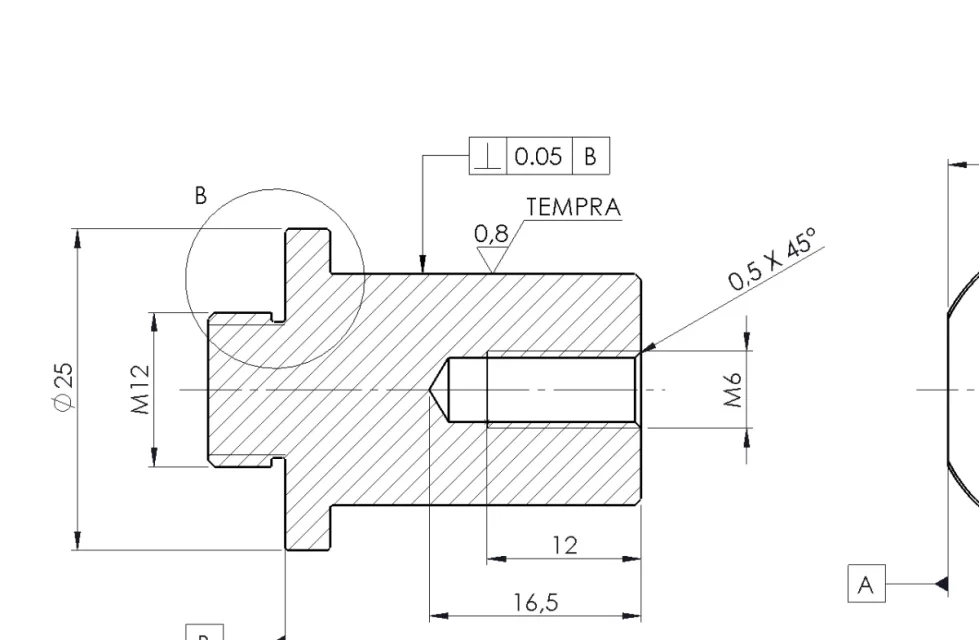

I tried to search everywhere on the net but without success... I admit I'm inexperienced and so I ask for the help of those who know more about me in thermal treatments. I have to make a small pin/shaft in c45 on which rotates a toothed pulley through self-lubricating bushings. the bushing manufacturer suggests a hardness of 55 hrc and then with the supplier we decided to make a superficial selective tempering. in the drawing I simply wrote "tempra" above the indication of superficial roughness (0,8) but I would like to indicate it more clearly... Help me?

I tried to search everywhere on the net but without success... I admit I'm inexperienced and so I ask for the help of those who know more about me in thermal treatments. I have to make a small pin/shaft in c45 on which rotates a toothed pulley through self-lubricating bushings. the bushing manufacturer suggests a hardness of 55 hrc and then with the supplier we decided to make a superficial selective tempering. in the drawing I simply wrote "tempra" above the indication of superficial roughness (0,8) but I would like to indicate it more clearly... Help me?