Meteor02

Guest

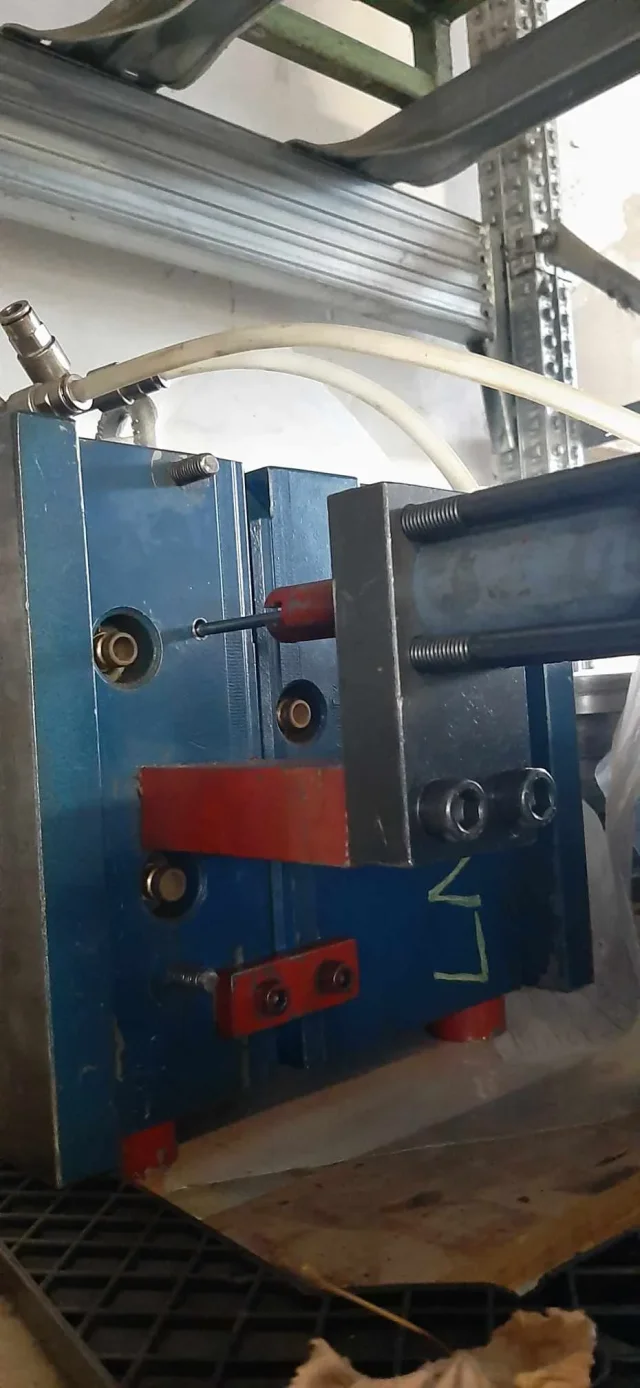

It's not that everything's okay in plastic, but it's just like that. I don't know what printers you have to deal with, but give today and tomorrow the molds clean regularly and if you die as god commands the gases that go dirty are really negligible. is a pivot that flows 1/2 times a minute not a piston at 5000 laps does not grip. to make a hole you do not need to end it is enough to calibrate the thickness of the piston, in plastic to make stupid holes you can also use air pistons (I put one in photo) and do not trouble even those figurative if it grips a hydraulic piston. maintenance and discards with 2 pistons you do not have, with a closure to shave as hypothesized you must predict periodic maintenance to resume the surfaces to rub. for this the advice when one has to make a mold is always the one asked the printer easily in his career will have seen all the available solutions and many will have tested and evaluated in production.Forgive me. . Maybe in plastic everything is fine, but I would never do a job like that. if it grips the hamster and madonne to pull it out and ruin the hole as well.

Perhaps I would put a telescope or compass on it, so that in case of grip it is easy to remove everything.

Obviously the telescope or compass implies a system of platelets to block everything.

The conical hole, if you infiltrate the dirt, give today tomorrow.. the scrolling pin remains backward and therefore creates a gag.

that to say.. that your inexpensive depends on the characteristics of the piece you have to produce and especially on the daily numbers of printed with consequent machine stop for maintenance and scrap of pieces.

in any case the cylinders and the ends do not give them to you.

If you need to print an object that goes into a wall.. Everything is fine