Felixanderdb

Guest

Good morning to all,

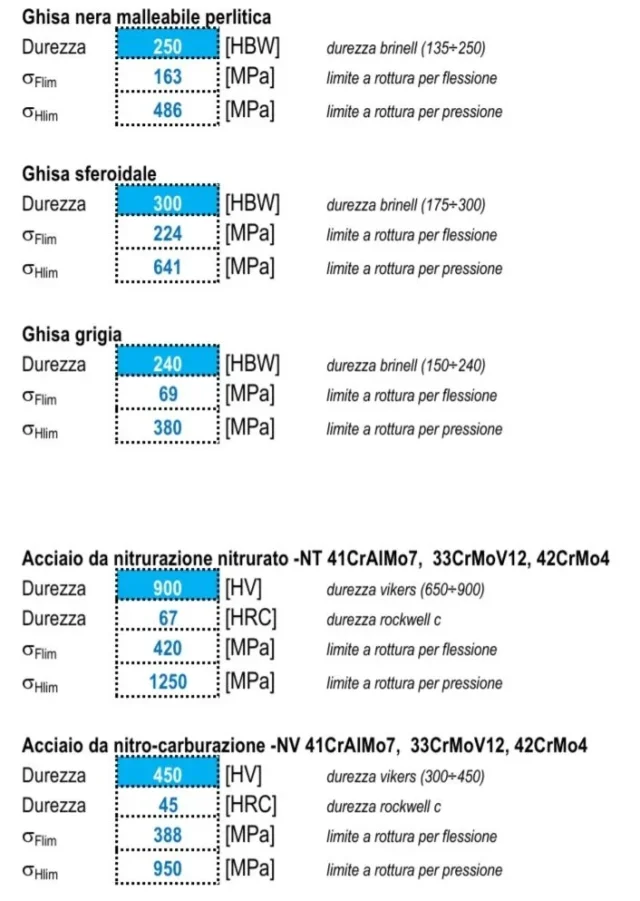

This is the first time I write on the forum. I'm felixanderdb, a mechanical engineer and at work I was asked to dimensional dense wheels. In particular, I was wondering, as to the legislation that is reported in the subject of the discussion, I wondered how it is possible for each steel or aluminum to fit it into the right category and then find resistance to bending and pitting. Excuse me if the question has already been asked.

thanks for any answers.

This is the first time I write on the forum. I'm felixanderdb, a mechanical engineer and at work I was asked to dimensional dense wheels. In particular, I was wondering, as to the legislation that is reported in the subject of the discussion, I wondered how it is possible for each steel or aluminum to fit it into the right category and then find resistance to bending and pitting. Excuse me if the question has already been asked.

thanks for any answers.