the three volumes of niemann are practically out of sale and are found almost exclusively in the library of engineering universities.

if you work with the rules

iso 6336 treats all design, including materials and their treatments, as well as voltage values permissible to bending and wear. has different parts, and each explains something specific.

If you look

This is what discussion can be found for example the characteristics of the materials indicated in ISO 6336-5. read well all that there are links that explain well.

an industrial mechanical reducer transmits high pairs in reduced volumes.

already the type and conformation of the axes can determine more or less compactness.

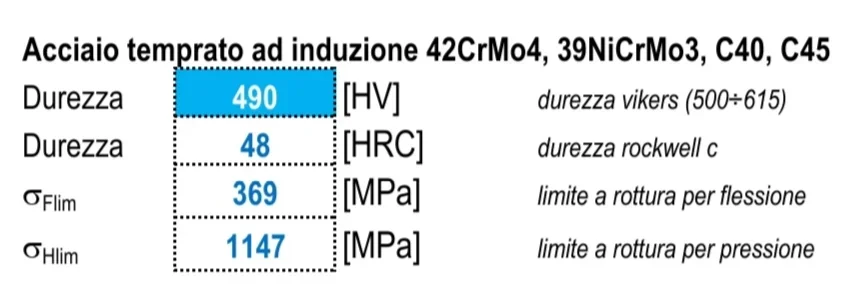

if you turn at higher regimes you have a more accentuated wear and you can not use normalized materials.

equal weight, an iron gear holds practically nothing. using hardened carbon steels then you already have a considerable load capacity even if it is a little "fragile" with time and strong stresses. hardened steels are a good compromise of resistance-wear-cost. cementing steels are the top of the range for strength.

another free book that is on the net is written by bonfiglioli and is

manual of the motor....where you find the calculation formulas for gears according to the first version of iso 6336.

if you provide us with more details (power/giri input, reduction ratio, number stages, type of use and field of use.....) we can also make a reasoning.

We don't want to replace you, but if you want concrete help, you need to share information.