ilfrau

Guest

Hello everyone,

what I would like to do is a cam exactly like that of This video.

use both the wf5 and I create 2.

I have the law of motion I want to assign to the rotation of the tower according to the rotation of the cam.

in mechanism environment, I made the trace curves of some points of the roller that I used to cut the cam with surfaces or with variable section sweep.

for now, I tried to cut only one channel (three in total).

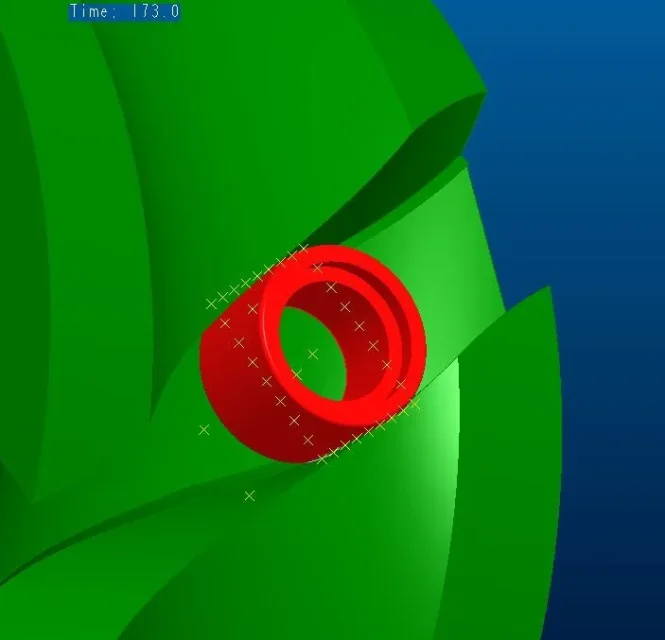

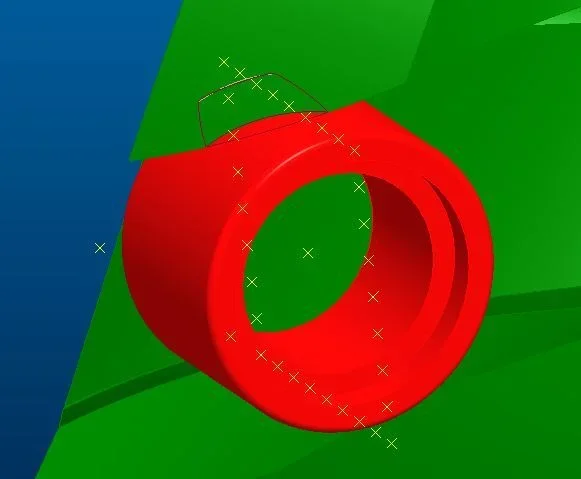

the cut was decent but there were points where I interlinked between cam and rollers; especially at the beginning and end of the cut (see attached pictures).

so I thought I had to turn the roller plane where I put the points for the trace curves. the situation improved, but the motion law I assigned to the roller plane was random: a sinusoidal law, like the main one of the tower, which in half reverses the direction (otherwise the cutting plan turns too much on itself).

but, what is the right movement law to assign to the roller cutting plane?

How would you do that?

would you tell me where I can find more detailed information about this type of 3d modeling?

I searched on the web, but I did not find anything except videos like what I attached in which, however, you can not see how to do.

Thank you.

Goodbye

what I would like to do is a cam exactly like that of This video.

use both the wf5 and I create 2.

I have the law of motion I want to assign to the rotation of the tower according to the rotation of the cam.

in mechanism environment, I made the trace curves of some points of the roller that I used to cut the cam with surfaces or with variable section sweep.

for now, I tried to cut only one channel (three in total).

the cut was decent but there were points where I interlinked between cam and rollers; especially at the beginning and end of the cut (see attached pictures).

so I thought I had to turn the roller plane where I put the points for the trace curves. the situation improved, but the motion law I assigned to the roller plane was random: a sinusoidal law, like the main one of the tower, which in half reverses the direction (otherwise the cutting plan turns too much on itself).

but, what is the right movement law to assign to the roller cutting plane?

How would you do that?

would you tell me where I can find more detailed information about this type of 3d modeling?

I searched on the web, but I did not find anything except videos like what I attached in which, however, you can not see how to do.

Thank you.

Goodbye