HuddSyd

Guest

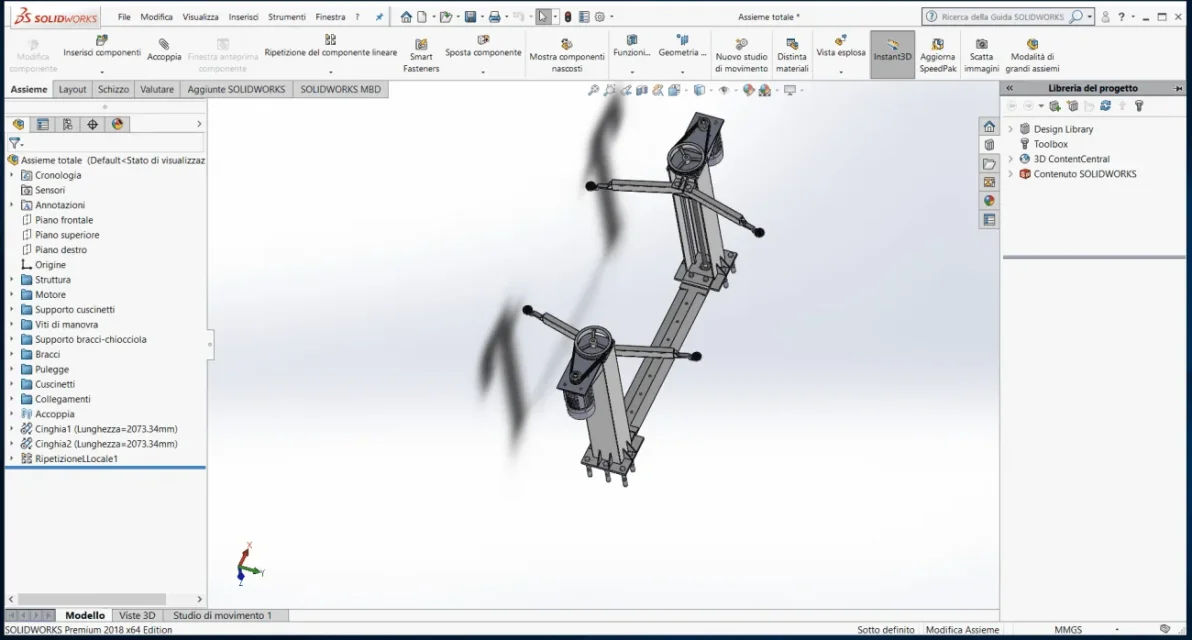

Save as from title my set gives me this problem

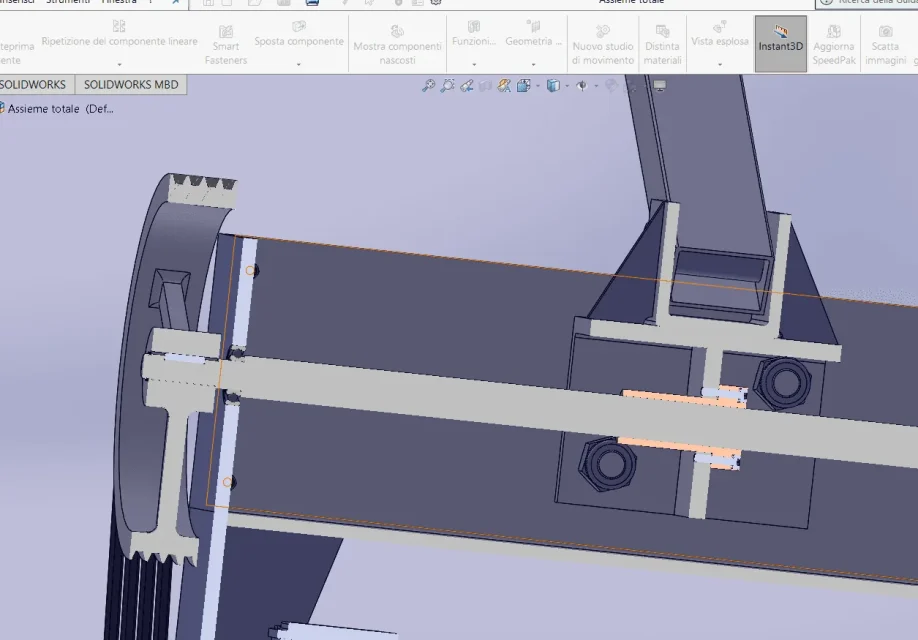

In "total assemblies" this problem appears to me once I give to "arms-kidle support" a minimum and maximum distance bond to avoid the interlinks between the various parts. then to make the message disappear I put the flexible "323035" bearings instead of rigid once this is done, the "manage screw" translates as if the 32305 bearing was dismantled, so I go to set that the screw of maneuver is stuck to the translation but then the error recompaiaias

I tried both using the bearings taken from the skm catalog of the manufacturer (as axiemi), and the bearings taken from the internal skm catalog to solidworks (as parts), and taking the first and going inside the various axiemi to add the relationships to avoid disassembly, but nothing the error does not disappear, however suspect that even the upper radial bearing should be adjusted together with the couplings

attached there is a link with all files if someone wanted to try out the business and give me a hand

I apologize if the axieme presents a very "barbarbara" form of how it should be instead in the design reality

but I use this program recently

thank you all, to whom will give me a hand and to those who have read herehttps://www.dropbox.com/sh/4hu4sq7w43g8yy3/aadiaf-fx2pogbscbjixhzu6a?dl=0

In "total assemblies" this problem appears to me once I give to "arms-kidle support" a minimum and maximum distance bond to avoid the interlinks between the various parts. then to make the message disappear I put the flexible "323035" bearings instead of rigid once this is done, the "manage screw" translates as if the 32305 bearing was dismantled, so I go to set that the screw of maneuver is stuck to the translation but then the error recompaiaias

I tried both using the bearings taken from the skm catalog of the manufacturer (as axiemi), and the bearings taken from the internal skm catalog to solidworks (as parts), and taking the first and going inside the various axiemi to add the relationships to avoid disassembly, but nothing the error does not disappear, however suspect that even the upper radial bearing should be adjusted together with the couplings

attached there is a link with all files if someone wanted to try out the business and give me a hand

I apologize if the axieme presents a very "barbarbara" form of how it should be instead in the design reality

but I use this program recently

thank you all, to whom will give me a hand and to those who have read herehttps://www.dropbox.com/sh/4hu4sq7w43g8yy3/aadiaf-fx2pogbscbjixhzu6a?dl=0