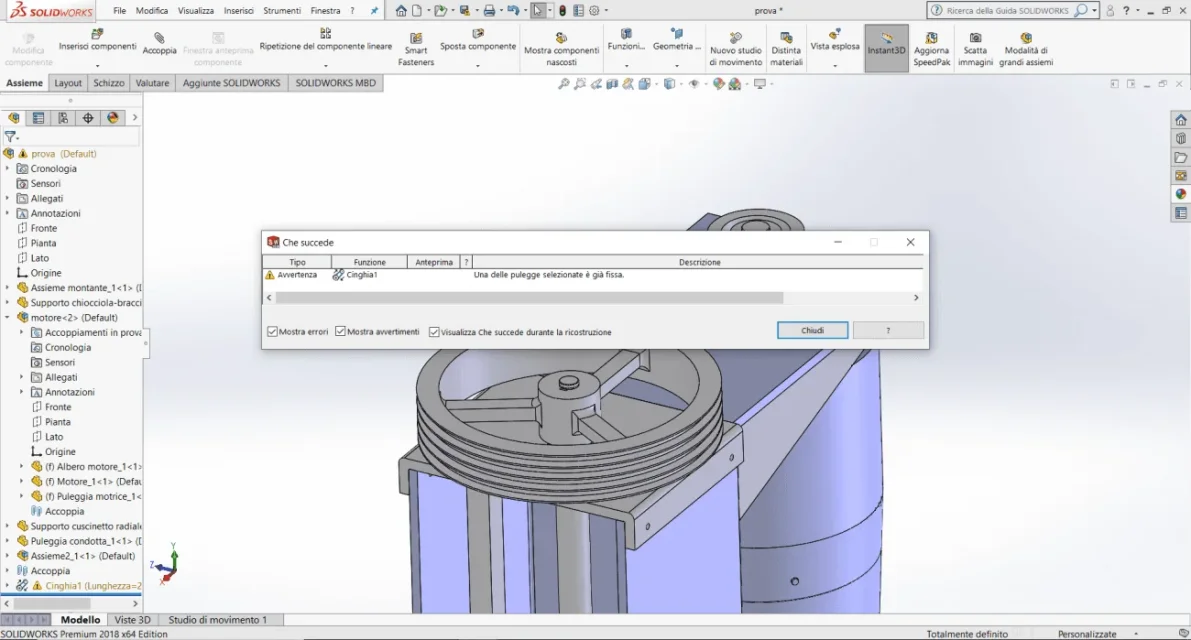

I opened your step now and...

-contains only one more motere, pulleys and ring support and other things. all the rest is missing

- Tell me that he's loaded it wrong and you didn't do the fit together but as a multibody part... It's an abomination. welded parts should be made with multibody method

- engines, if they do not need rendering, do not use those downloaded full of details such as fins, wineries, logos... because they weigh a lot at the processing level in the assemblies and even more at the design level. a cylinder is made to represent the body, a cylinder to represent the tree and a rectangle to represent the box.

If you haven't done the multibody parts I can't help you at this point because managing the project, which doesn't seem complicated to me, to show you how to do the couplings would take too long.

as I imagine that remake the details, and above all the tutorials of the prograama (the ones inside and not the ones randomly caught on youtube) is deleterious for you you should take the assemblies of the welded and save them as part. In this way you have many less constraints to manage and if you are wrong and you have to reassemble you don't take days.