Pol_13

Guest

Good morning to all,

I'm a new user and I'm addressing the immense knowledge of the community to solve a problem that I can't handle.

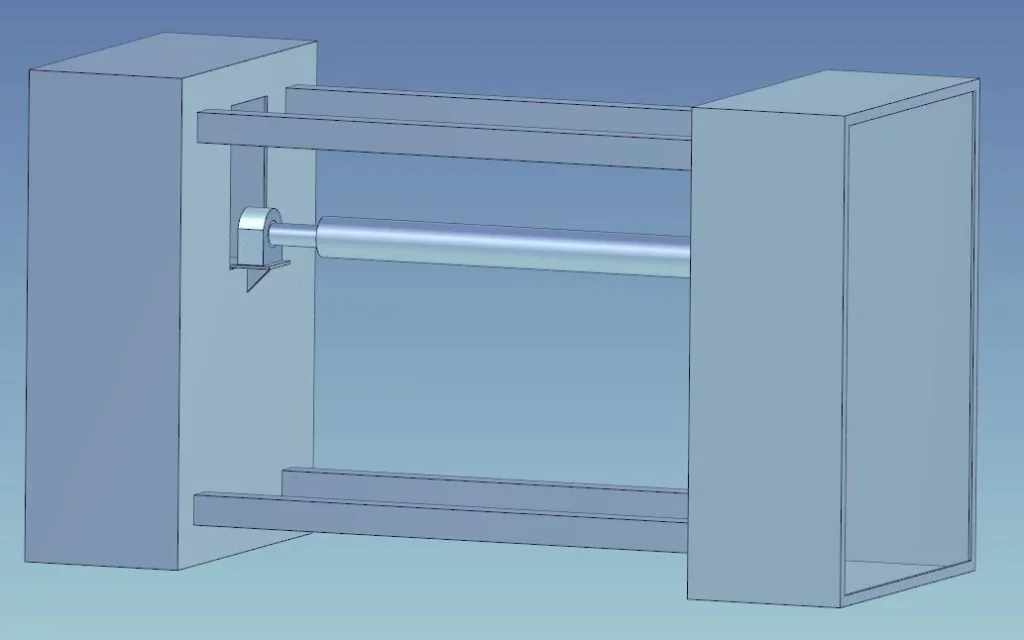

the structure that I have to realize is mainly composed of two sheets boxed in c40 that act as shoulders, connected between them by 4 rods always in c40 (imagine two boxes of the shoes put one in front of the other standing with the long side as height). the problem is that I do not know how to dimensional the thickness of the sheets that make up the shoulders, taking into account that on the face turned inside (the one on which the rods are bound) a window will be drawn on which a small support will be supported (shaft clamp) and therefore will be discarded the weight of the cylinder supported by the two supports.

what approach should I apply to estimate sheet thickness?

I'm a new user and I'm addressing the immense knowledge of the community to solve a problem that I can't handle.

the structure that I have to realize is mainly composed of two sheets boxed in c40 that act as shoulders, connected between them by 4 rods always in c40 (imagine two boxes of the shoes put one in front of the other standing with the long side as height). the problem is that I do not know how to dimensional the thickness of the sheets that make up the shoulders, taking into account that on the face turned inside (the one on which the rods are bound) a window will be drawn on which a small support will be supported (shaft clamp) and therefore will be discarded the weight of the cylinder supported by the two supports.

what approach should I apply to estimate sheet thickness?