New Rider

Guest

Thank you guys for the attention. Thanks kakisan of the example (just a second I look at it )

)

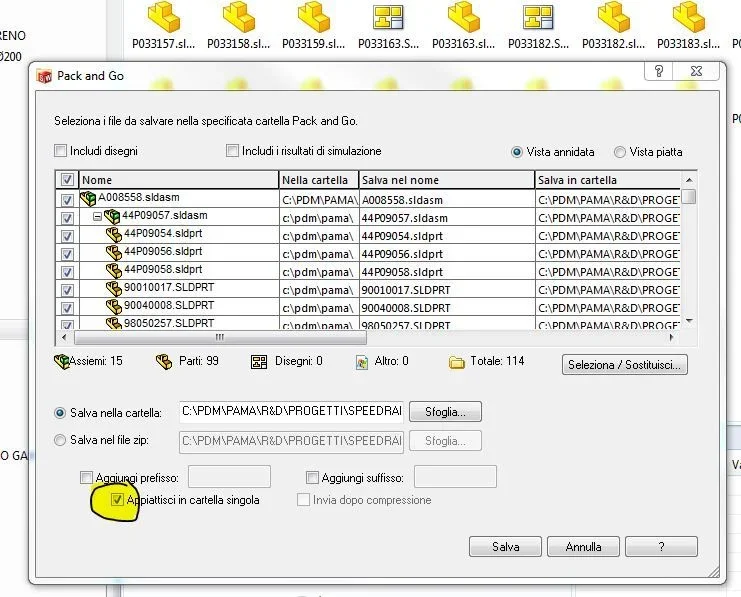

But I wanted to understand... We talked about axioms and axioms. the main idea is to group more components in an orderly manner to facilitate the identification.

what you advise in a proportionate way is to work with more sub-axis or try to group by e.g. the vice, bearings, seggers, rings etc... in "folders".

for es = classic toothed wheel reference tree to be inserted in a very "macro" consisting of 2 supports, 2 bearings,2 segger,2 spacers and toothed wheel and tree. should you create a subset and call it (referral) in which it will be in the newly cited components and insert it into the "macro" or insert each component into the macro axieme and then move the components into your folders?

Thank you. .

p.s = recently in my personal pc I installed a ssd and from that point on the performance in terms of sw time is improved a lot. It is possible that slow coupling rather than difficulty opening files depend on the fact that all axioms and files are written on external servers (like a kind of lag? ).

But I wanted to understand... We talked about axioms and axioms. the main idea is to group more components in an orderly manner to facilitate the identification.

what you advise in a proportionate way is to work with more sub-axis or try to group by e.g. the vice, bearings, seggers, rings etc... in "folders".

for es = classic toothed wheel reference tree to be inserted in a very "macro" consisting of 2 supports, 2 bearings,2 segger,2 spacers and toothed wheel and tree. should you create a subset and call it (referral) in which it will be in the newly cited components and insert it into the "macro" or insert each component into the macro axieme and then move the components into your folders?

Thank you. .

p.s = recently in my personal pc I installed a ssd and from that point on the performance in terms of sw time is improved a lot. It is possible that slow coupling rather than difficulty opening files depend on the fact that all axioms and files are written on external servers (like a kind of lag? ).