Olan

Guest

hi, I have a problem, I had created a discussion about industrial design and I would not want to create doubles but the question is now specific to solidworks then. .

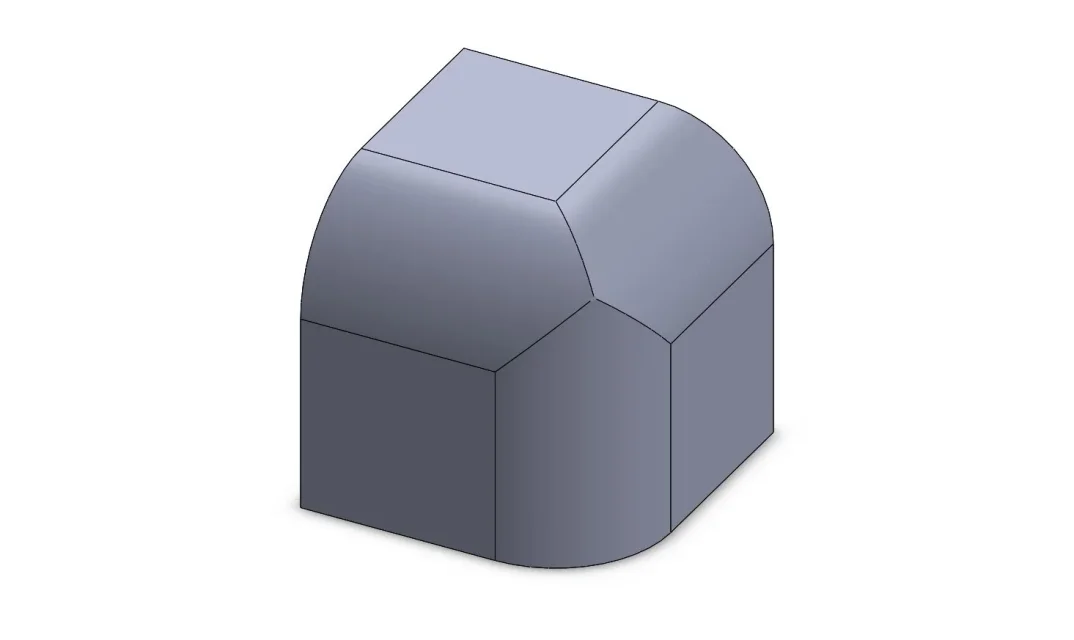

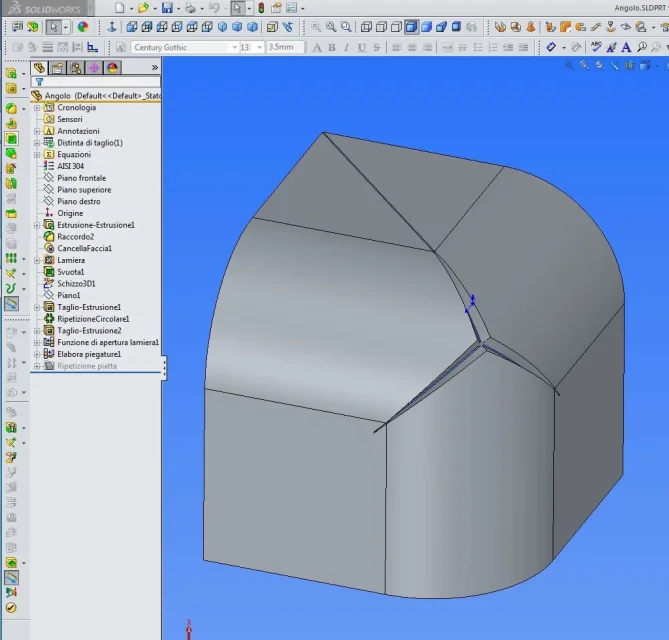

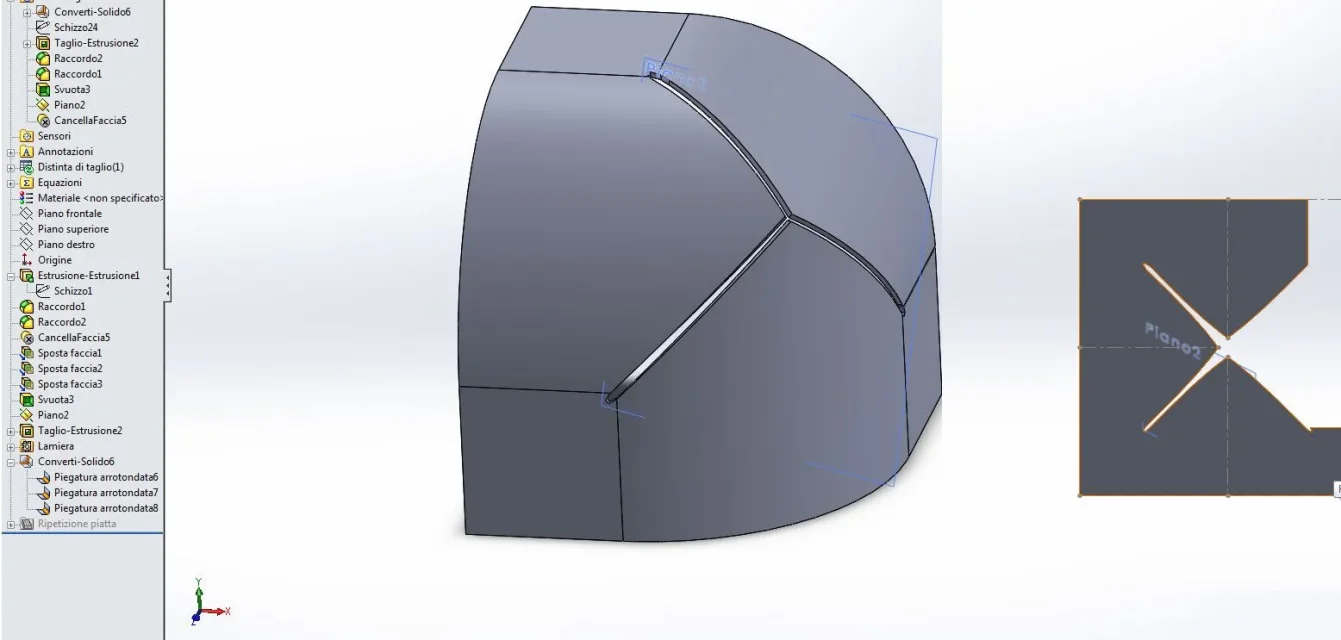

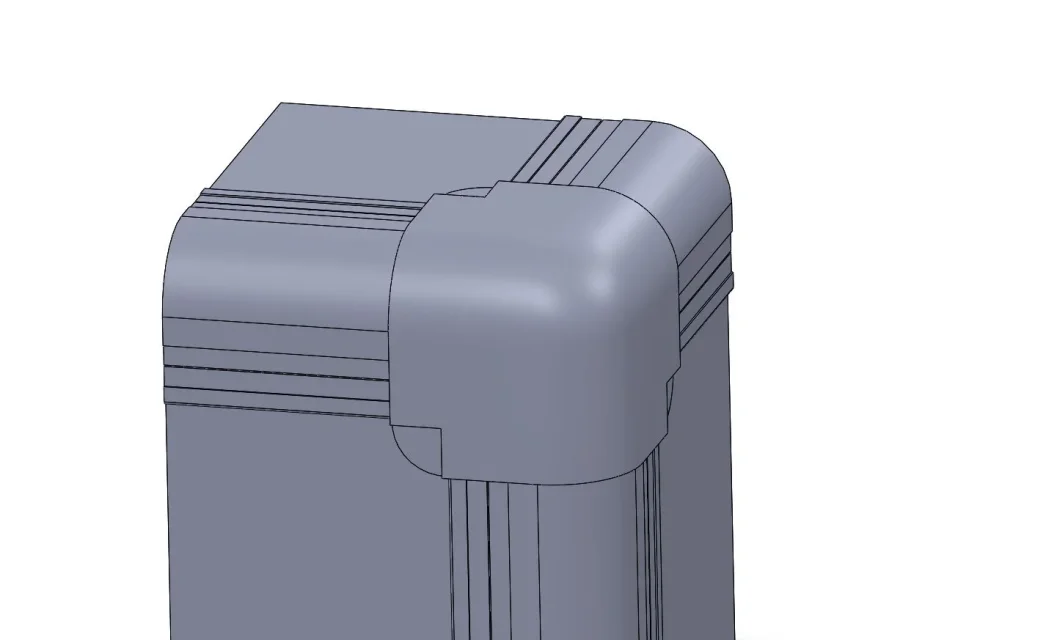

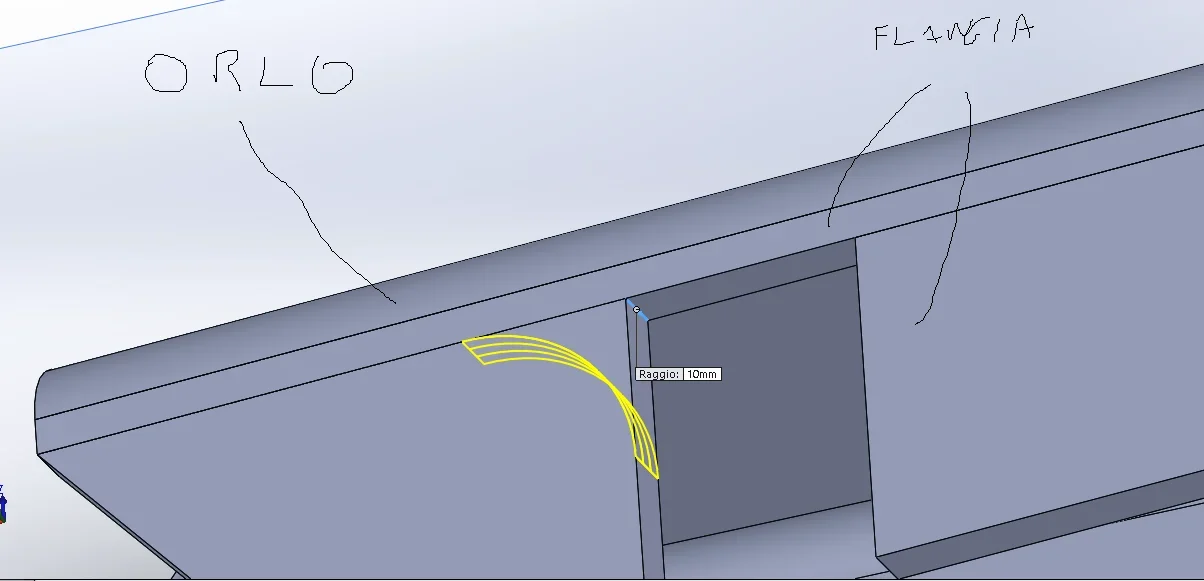

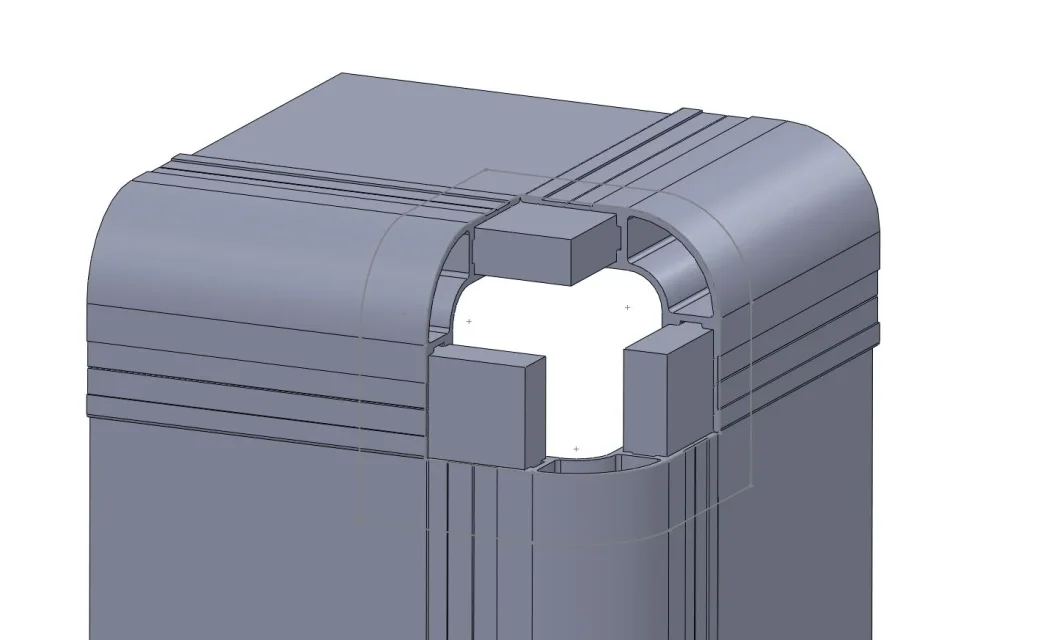

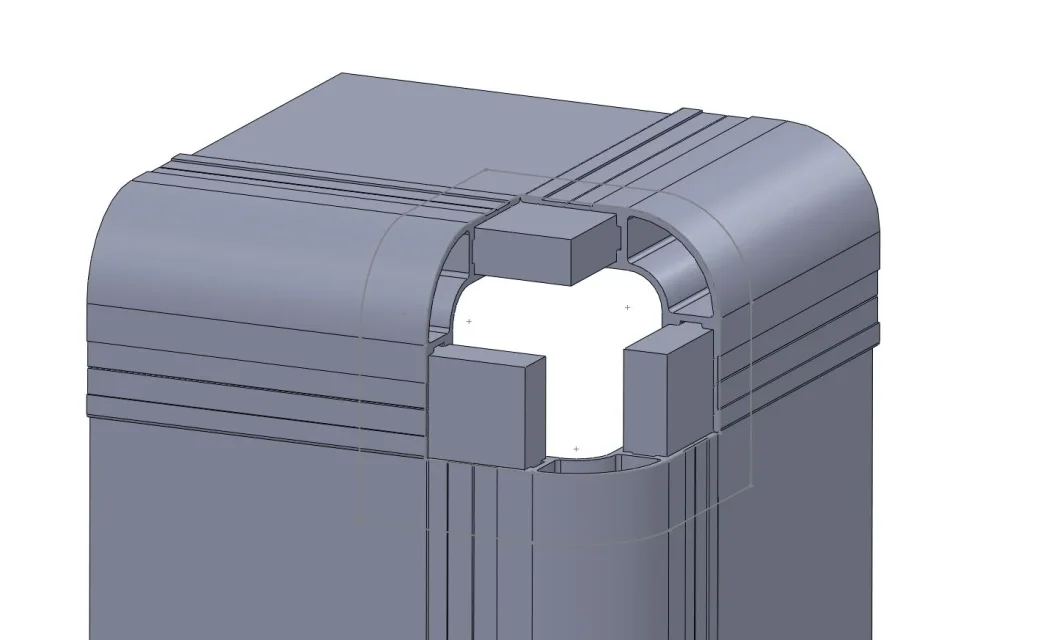

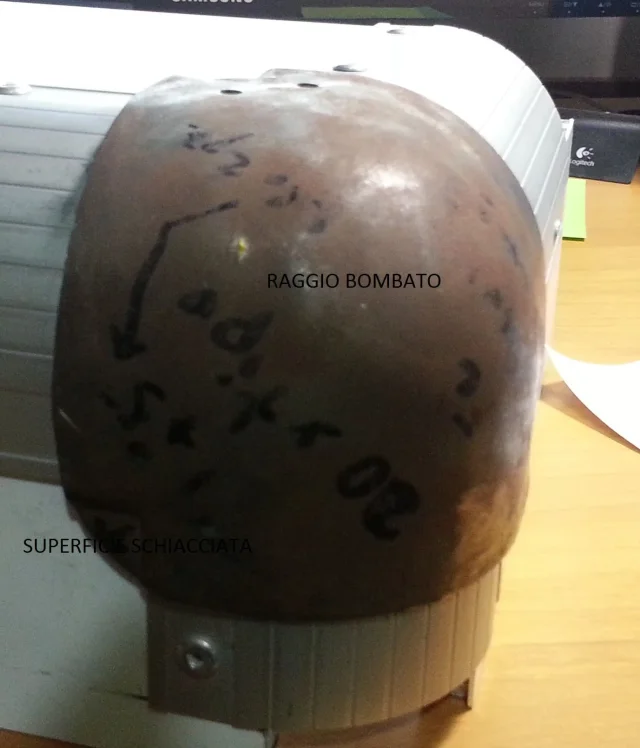

I have to create a fitting sheet (see attached picture) how can I do it? the result is that in the photo.

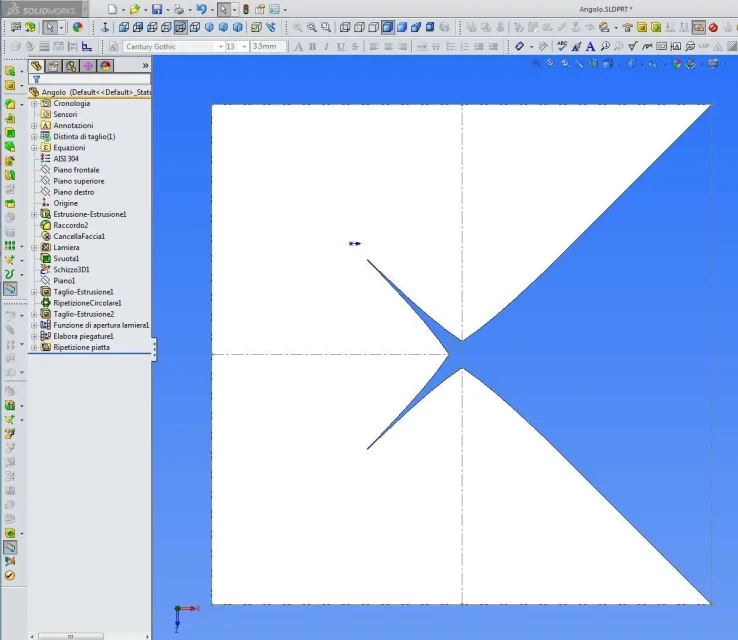

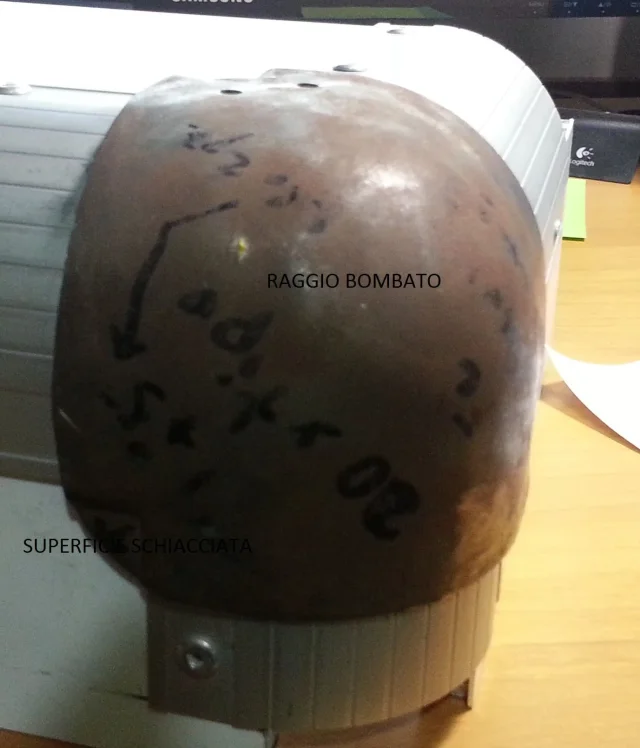

created the sheet metal I must then bend it into the ends and "bomb" in the center presumably with a forming instrument. .

going by step I guess you have to use "full with loft" but I just don't get it. .

Thank you.

Thank you.

I have to create a fitting sheet (see attached picture) how can I do it? the result is that in the photo.

created the sheet metal I must then bend it into the ends and "bomb" in the center presumably with a forming instrument. .

going by step I guess you have to use "full with loft" but I just don't get it. .

Thank you.

Thank you.