G.Moroni

Guest

Hello everyone,

I am new in the forum and this is my first discussion.

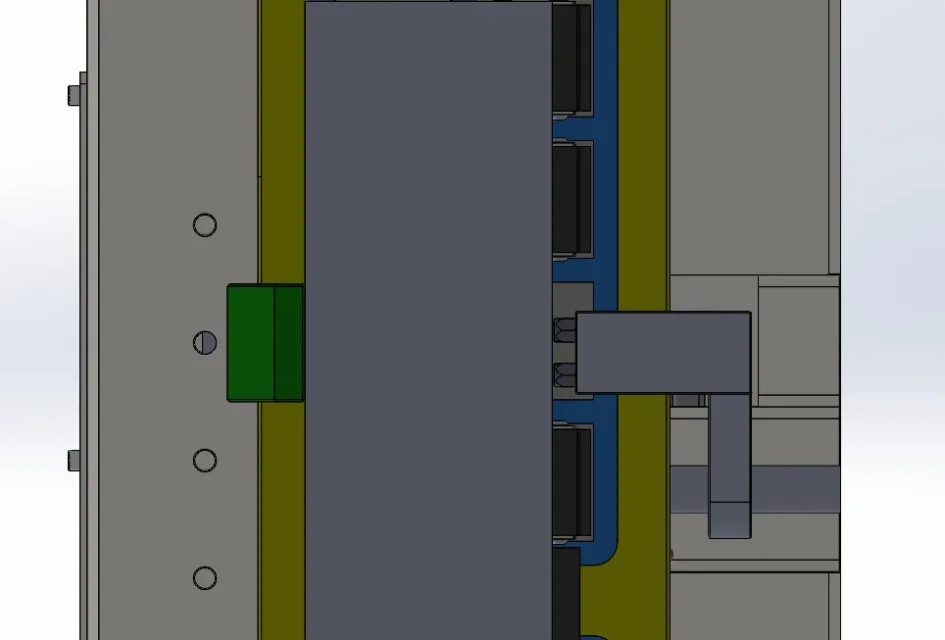

in short: we are designing a clamping equipment for structural components in c45 1.1191. In the first phase I need to use hydraulic cylinders for positioning on fixed side feedback and then carry out the seal with magnetic plane (img. 4).

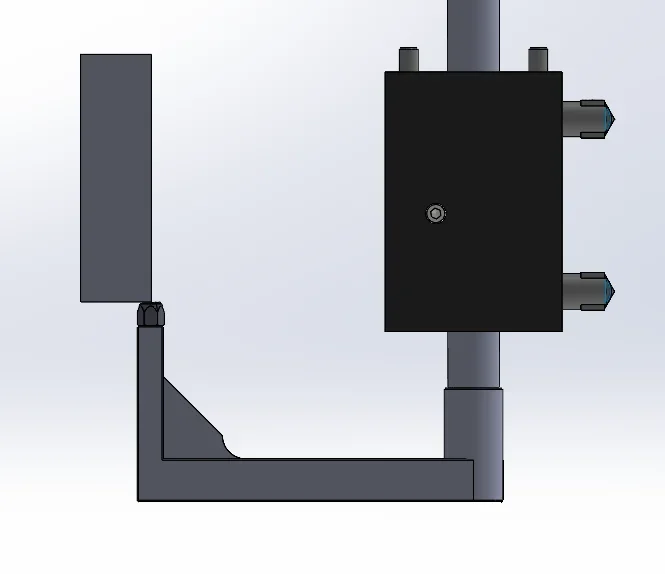

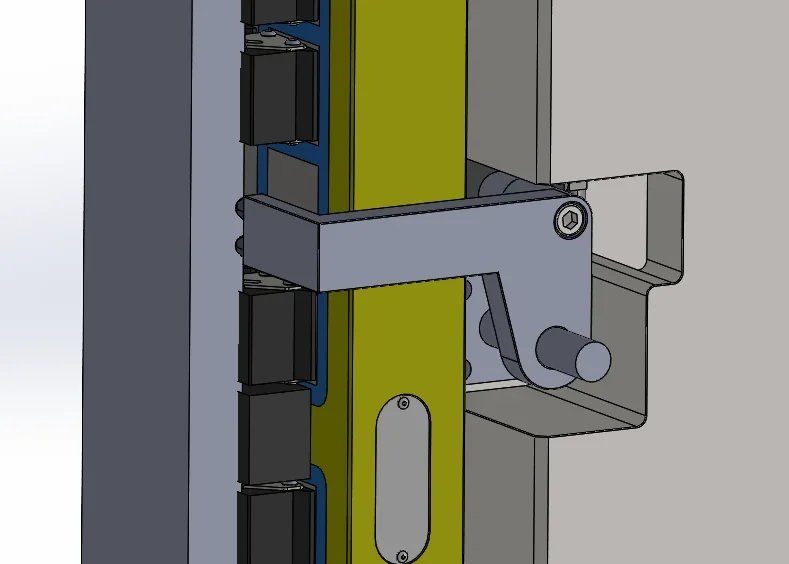

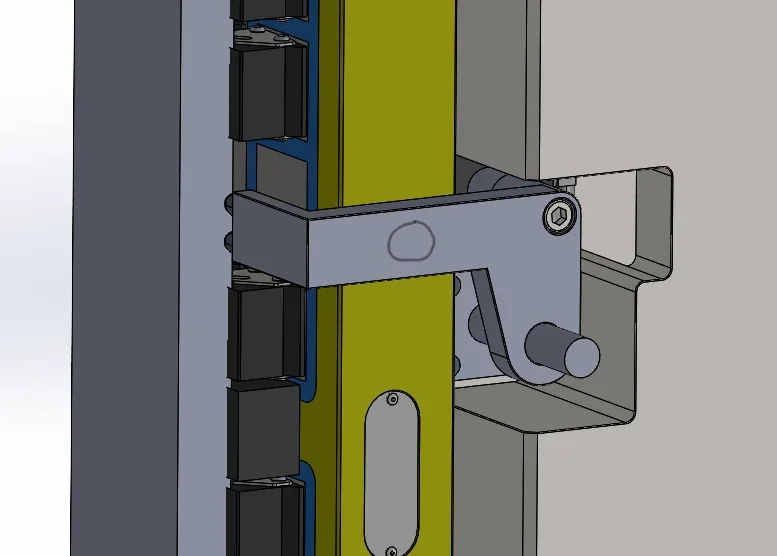

here arises my question: going to work 140mm out axis the cylinder rod would go under a radial force that would cause excessive wear of the bearings (img.1). to overcome the problem I thought of inserting a side guide (img. 2). Do you think that could be a good solution? would it be better to put the guide to the center directly on the floor(img.3)? I was advised to use a spherical joint at the end of the cylinder stem to cancel the radial force and make it totally axial, could it be a solution?

Thank you in advance.

I am new in the forum and this is my first discussion.

in short: we are designing a clamping equipment for structural components in c45 1.1191. In the first phase I need to use hydraulic cylinders for positioning on fixed side feedback and then carry out the seal with magnetic plane (img. 4).

here arises my question: going to work 140mm out axis the cylinder rod would go under a radial force that would cause excessive wear of the bearings (img.1). to overcome the problem I thought of inserting a side guide (img. 2). Do you think that could be a good solution? would it be better to put the guide to the center directly on the floor(img.3)? I was advised to use a spherical joint at the end of the cylinder stem to cancel the radial force and make it totally axial, could it be a solution?

Thank you in advance.