Marcus990

Guest

Good evening to all,

are rotten and work in a company that deals with the design and manufacture of industrial compressors for medium and large enterprises.

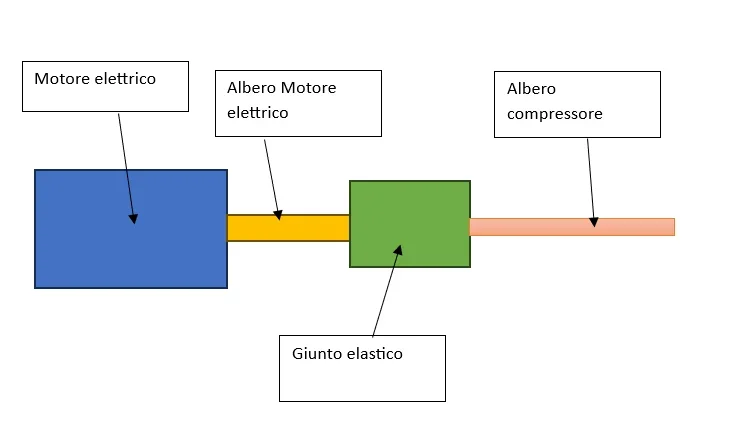

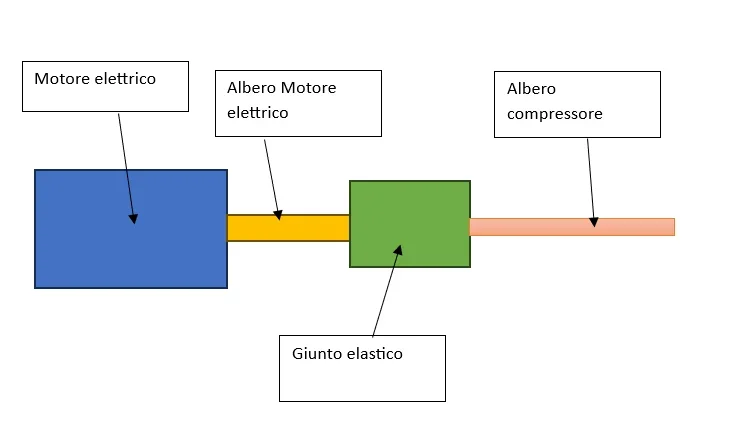

we are facing a particular problem at this time that consists in the rectification + rectification of a tree in 39crnimo3 (of the compressor) that will be thrown into an elastic joint, which will be thrown into another tree (of the electric motor), if it is not clear the scheme is as follows:

the 2 trees (motor and compressor) are coaxial and have a radial esiguous scaffolding, however after the remediation phase (tempra + tempering) it occurs that the compressor shaft (the one designed by us) goes out of tolerance, which I ovviato doing a first phase with overmetal then reclaim and finally the final processing.

the 2 trees (motor and compressor) are coaxial and have a radial esiguous scaffolding, however after the remediation phase (tempra + tempering) it occurs that the compressor shaft (the one designed by us) goes out of tolerance, which I ovviato doing a first phase with overmetal then reclaim and finally the final processing.

the professional who deals with doing these thermal treatments told us that the tempering for such a small tree (23 mm diameter) comes to the heart and then after hardnesses greater than 60 hrc becomes difficult to work.

Moreover with the solution echoed before, i.e. a tempra located only to the area that interests us it happened that the tree was disallined and also with the overmetal of 4/6 tenths it was impossible to recover it and bring it to the tolerances from drawing.

therefore the solution that comes to mind is to make an hardening on all the piece only superficially so that the overmetal to be lifted is not very much, however the one who heats us the trees said that by dive does not make it to harden them only superficially.

advice?

are rotten and work in a company that deals with the design and manufacture of industrial compressors for medium and large enterprises.

we are facing a particular problem at this time that consists in the rectification + rectification of a tree in 39crnimo3 (of the compressor) that will be thrown into an elastic joint, which will be thrown into another tree (of the electric motor), if it is not clear the scheme is as follows:

the 2 trees (motor and compressor) are coaxial and have a radial esiguous scaffolding, however after the remediation phase (tempra + tempering) it occurs that the compressor shaft (the one designed by us) goes out of tolerance, which I ovviato doing a first phase with overmetal then reclaim and finally the final processing.

the 2 trees (motor and compressor) are coaxial and have a radial esiguous scaffolding, however after the remediation phase (tempra + tempering) it occurs that the compressor shaft (the one designed by us) goes out of tolerance, which I ovviato doing a first phase with overmetal then reclaim and finally the final processing.the professional who deals with doing these thermal treatments told us that the tempering for such a small tree (23 mm diameter) comes to the heart and then after hardnesses greater than 60 hrc becomes difficult to work.

Moreover with the solution echoed before, i.e. a tempra located only to the area that interests us it happened that the tree was disallined and also with the overmetal of 4/6 tenths it was impossible to recover it and bring it to the tolerances from drawing.

therefore the solution that comes to mind is to make an hardening on all the piece only superficially so that the overmetal to be lifted is not very much, however the one who heats us the trees said that by dive does not make it to harden them only superficially.

advice?