bulfy98

Guest

Bye to all,

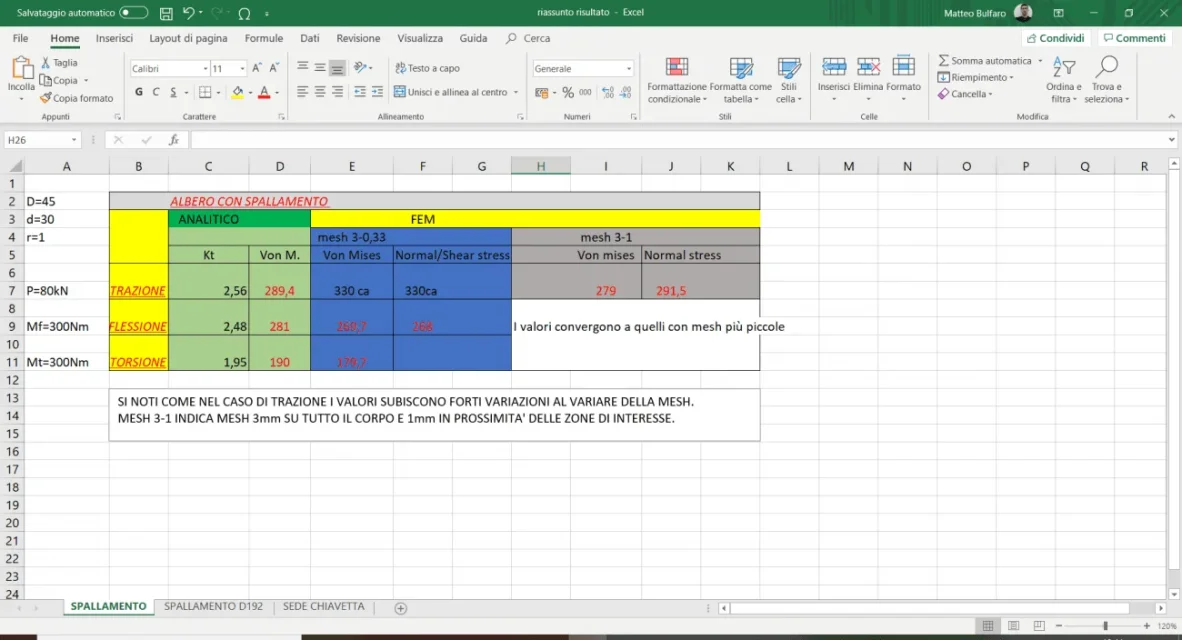

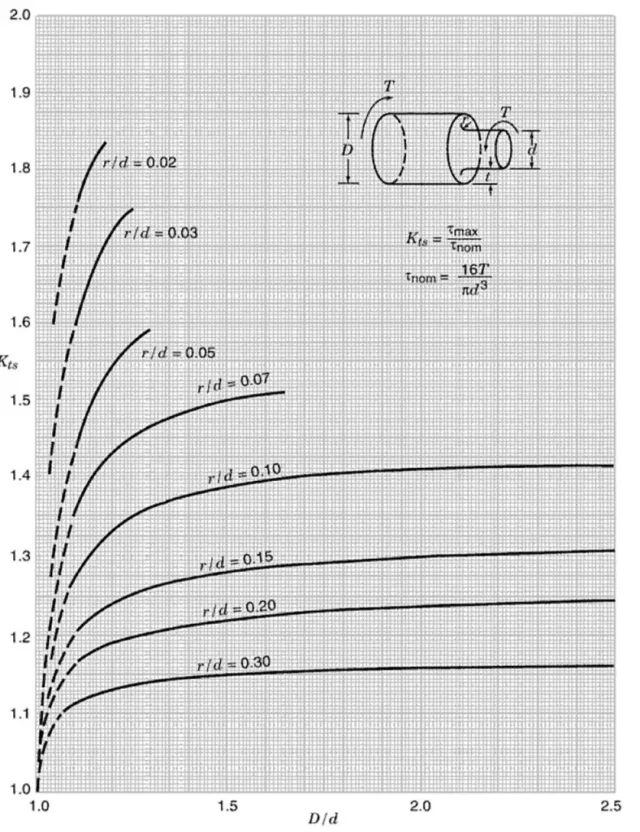

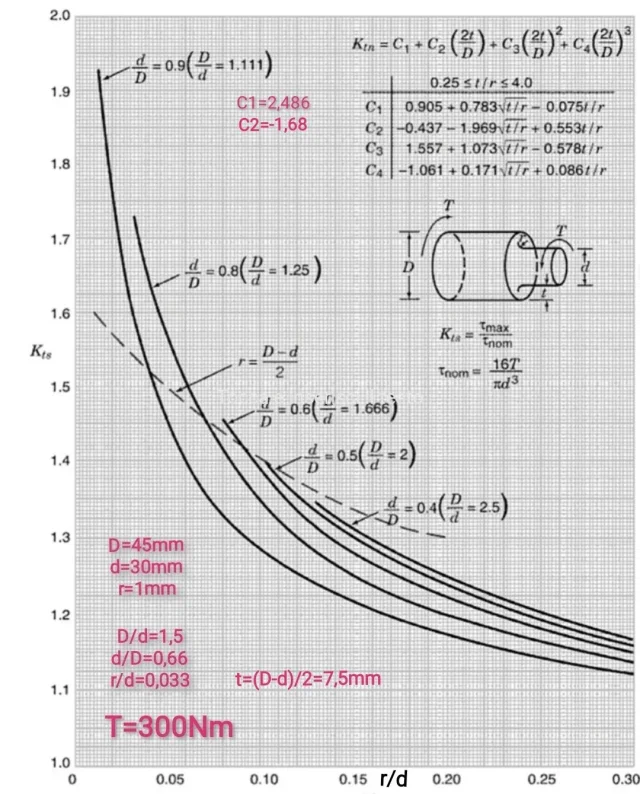

are at the very first experiences with ansys and the university asked me to compare analytical results and fem analysis for different trees with p=80kn traction, a bending and a torsion of 300nm each. all applied separately and in static with static structural.

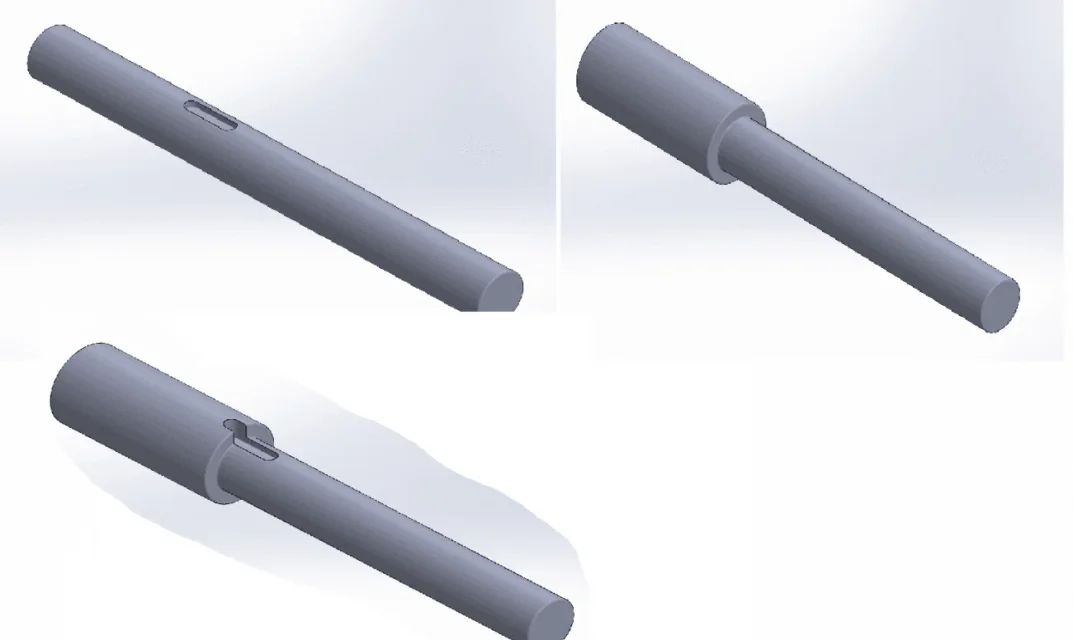

the trees are(I attach photos):

-d=45mm d=30mm shoulder with fitting r=1mm

-d=30mm with key seat

-d=45mm d=30mm with shoulder r=1 and seat for key that crosses the section

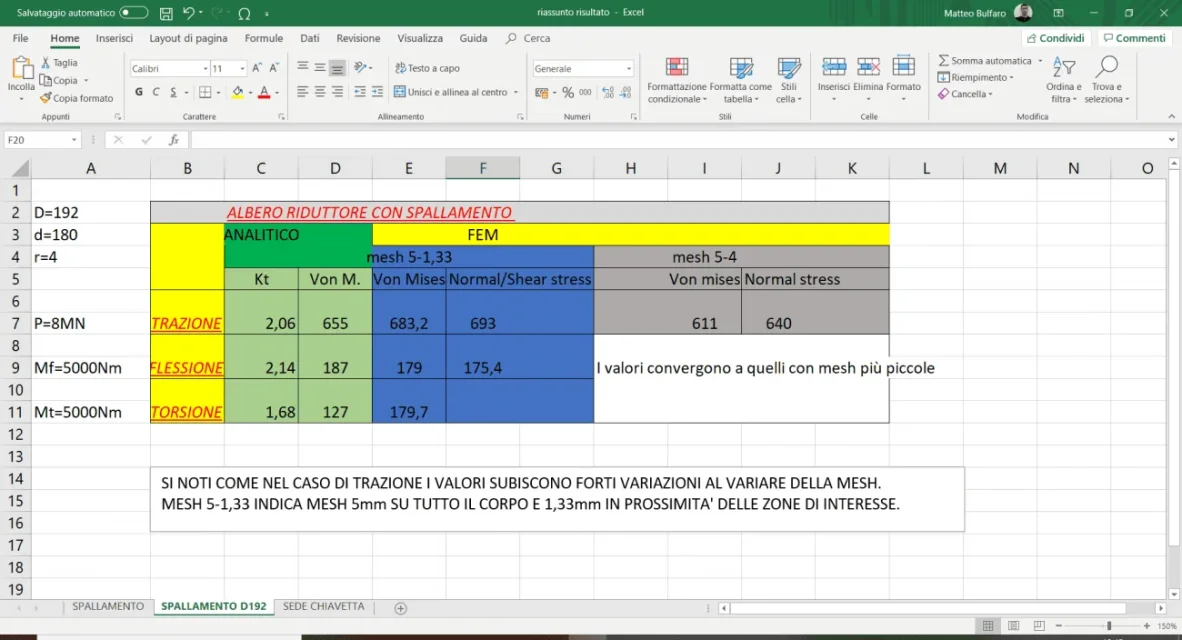

-d=192mm d=180mm shoulder with fitting r=4mm

My doubts, being novice, are the most trivial.

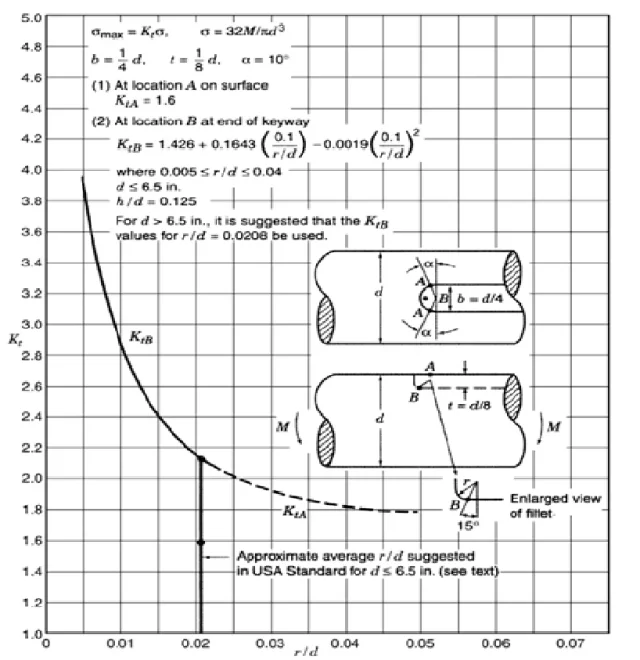

I have performed analytical calculations for all trees (except for the third of some nothing is present in literature) taking into account the kt carving factor and calculated tensions with von mises.

to compare the analytical results with the fem,how should I set the program? in particular:

-What stress calculation to adopt? equivanet von mises,normal,share? especially how to set them? I am always using equivalent von mises but sometimes the result does not converge well. What do you think?

-I would like to adopt a mesh of 1mm near the critical areas and wider elsewhere. How do you recommend doing this?

ps if you could motivate your choices you would make me a great pleasure, so understand why one so be the other not and learn more and more about this program.

thanks to all

are at the very first experiences with ansys and the university asked me to compare analytical results and fem analysis for different trees with p=80kn traction, a bending and a torsion of 300nm each. all applied separately and in static with static structural.

the trees are(I attach photos):

-d=45mm d=30mm shoulder with fitting r=1mm

-d=30mm with key seat

-d=45mm d=30mm with shoulder r=1 and seat for key that crosses the section

-d=192mm d=180mm shoulder with fitting r=4mm

My doubts, being novice, are the most trivial.

I have performed analytical calculations for all trees (except for the third of some nothing is present in literature) taking into account the kt carving factor and calculated tensions with von mises.

to compare the analytical results with the fem,how should I set the program? in particular:

-What stress calculation to adopt? equivanet von mises,normal,share? especially how to set them? I am always using equivalent von mises but sometimes the result does not converge well. What do you think?

-I would like to adopt a mesh of 1mm near the critical areas and wider elsewhere. How do you recommend doing this?

ps if you could motivate your choices you would make me a great pleasure, so understand why one so be the other not and learn more and more about this program.

thanks to all