meccanicamg

Guest

Here we are with a question that I need to solve.

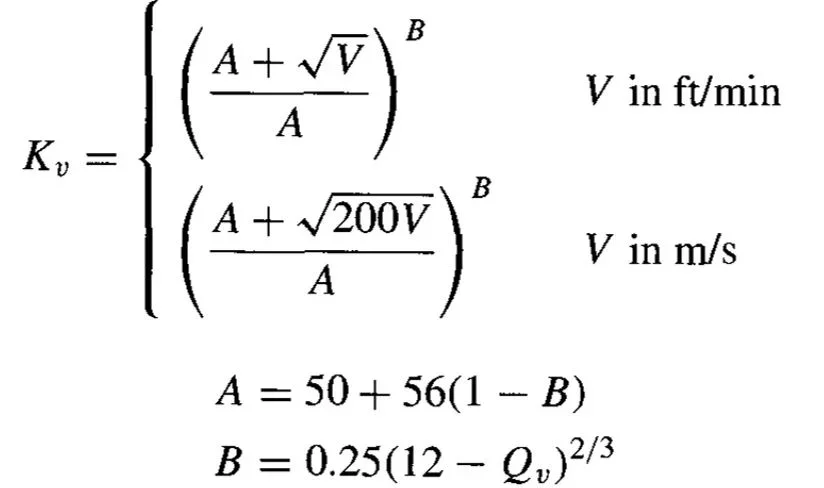

I am preparing an excel sheet for calculating a pair of external cylindrical wheels and I am using the ansi/agma 2101-d04 metric standard. to say the truth I have also consulted the previous agma and the din 3990 but history changes radically.

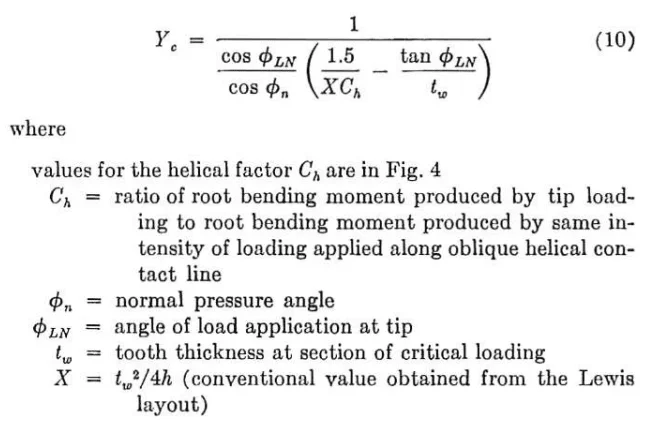

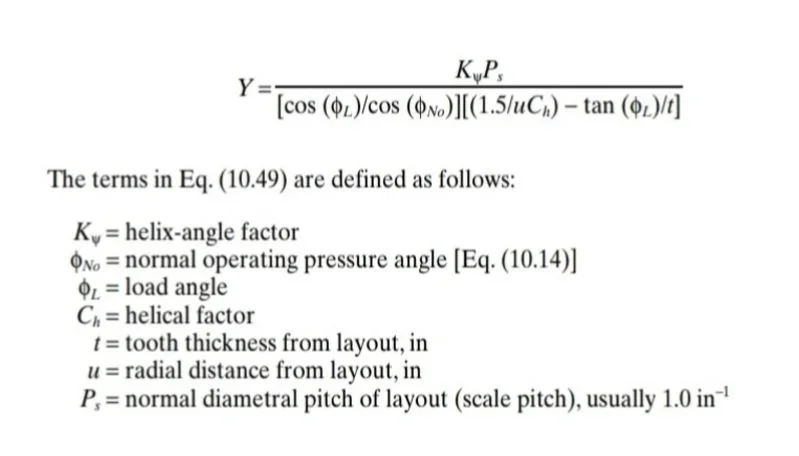

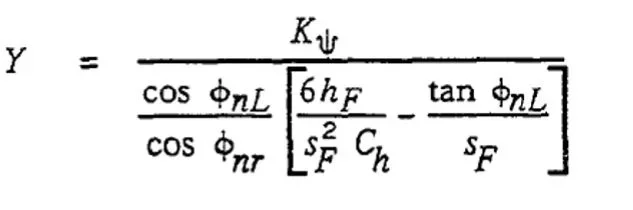

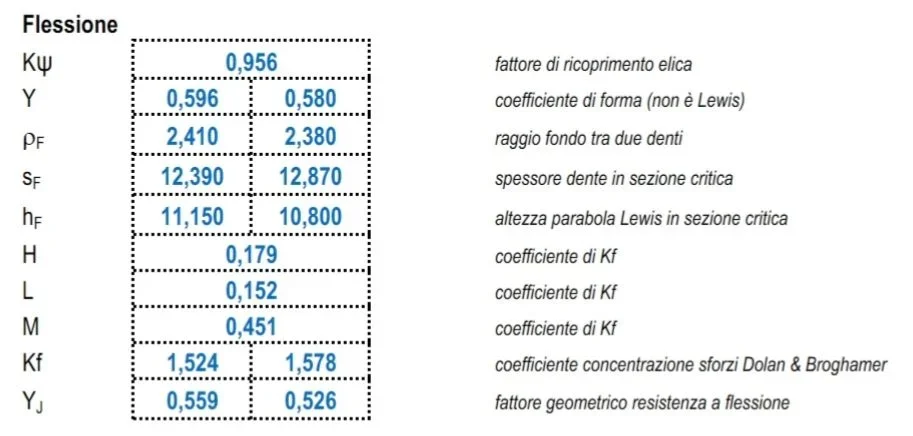

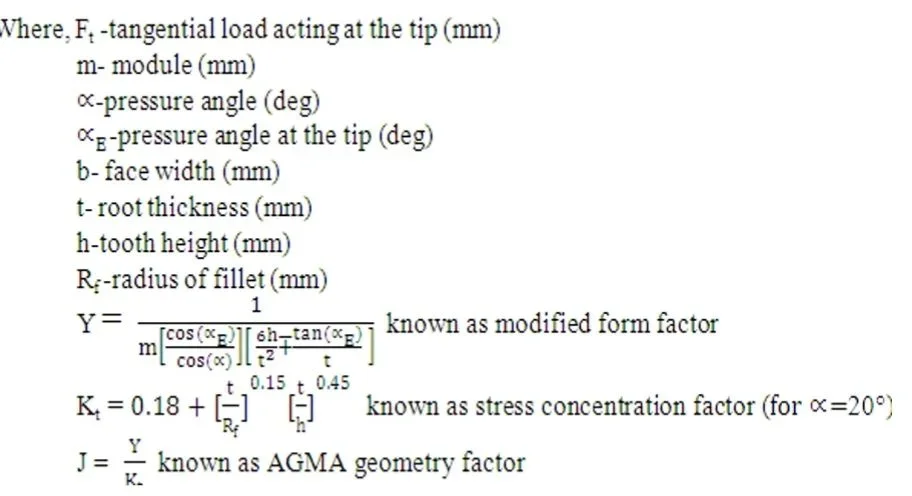

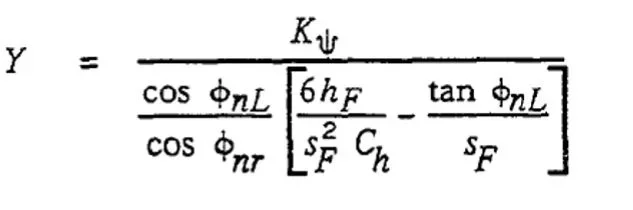

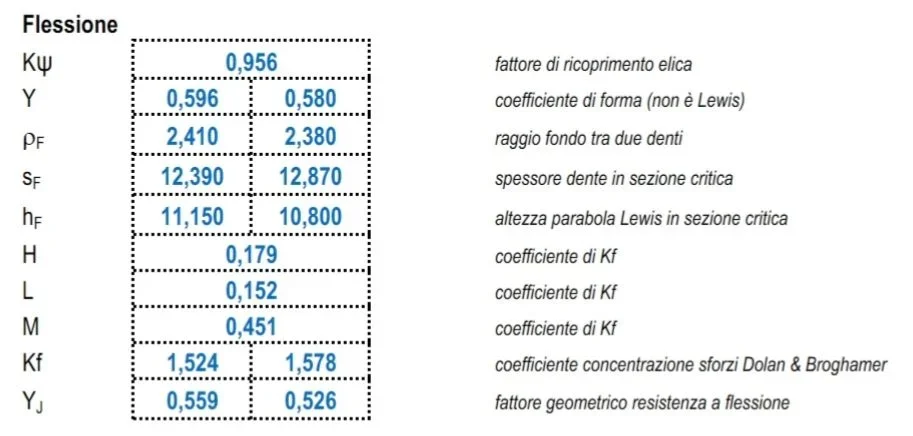

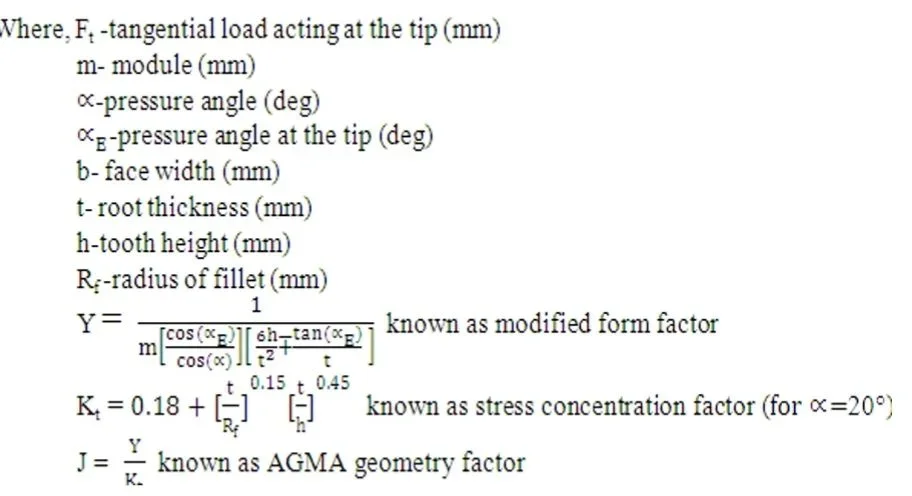

with the term y is indicated for the Americans the form factor that is not the factor of lewis, so says the norm and is less than 1.

I had the values calculated by kisssoft and I'm sure they're inconfutable. I can't count by hand.

♪

♪

mn=6

pressure angle = 20°

helical angle = 12°

interasse = 270mm

x1=+0,41730 profile shift with present subtitles

x2=+0,13268 profile shift

provided that I still have to find to correctly calculate the parable of lewis, I used thickness and height of the tooth in the critical section with the base beams of the tooth obtained from kisssoft.

with the following formula I come y1=2,96 al post di y1=0,596 and should be like this:

and should be like this: Can anyone help me out, please?

Can anyone help me out, please?

already in the formulas of kf I found that in a norm the radiants and other degrees are used.... Who knows that's something trivial. . .

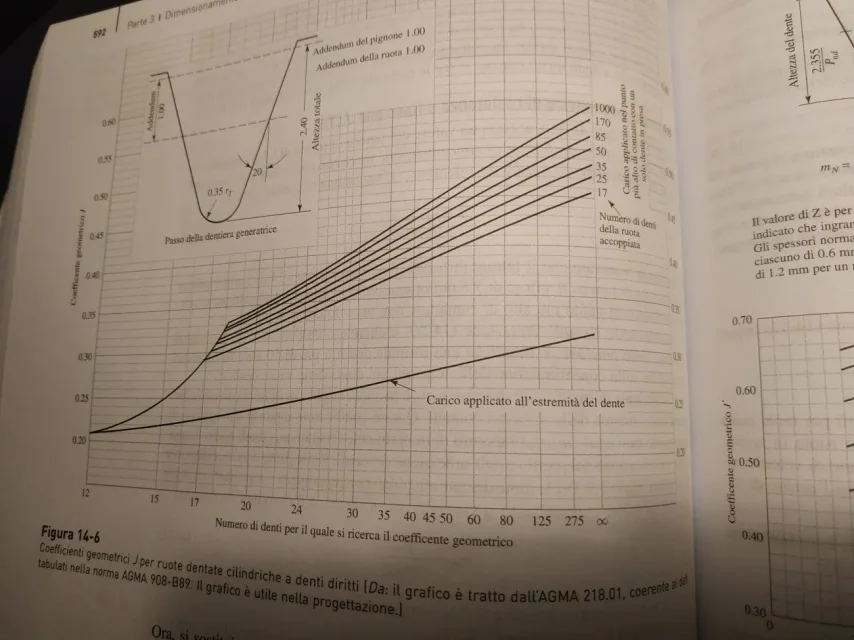

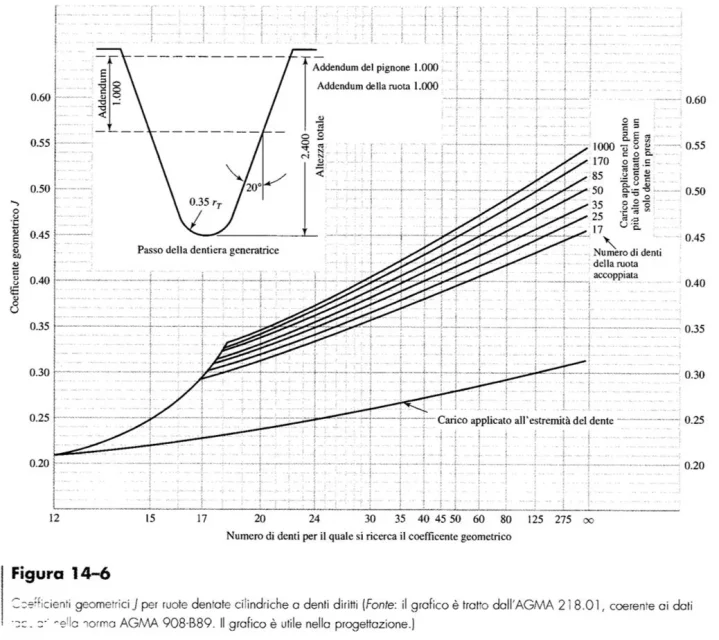

other formula provides me y1=0,418 but still we are not: Of course, for geometry, I'm using agma-908-b89, but it's not that I'm getting out of it a lot.

Of course, for geometry, I'm using agma-908-b89, but it's not that I'm getting out of it a lot.

I am preparing an excel sheet for calculating a pair of external cylindrical wheels and I am using the ansi/agma 2101-d04 metric standard. to say the truth I have also consulted the previous agma and the din 3990 but history changes radically.

with the term y is indicated for the Americans the form factor that is not the factor of lewis, so says the norm and is less than 1.

I had the values calculated by kisssoft and I'm sure they're inconfutable. I can't count by hand.

♪

♪

mn=6

pressure angle = 20°

helical angle = 12°

interasse = 270mm

x1=+0,41730 profile shift with present subtitles

x2=+0,13268 profile shift

provided that I still have to find to correctly calculate the parable of lewis, I used thickness and height of the tooth in the critical section with the base beams of the tooth obtained from kisssoft.

with the following formula I come y1=2,96 al post di y1=0,596

and should be like this:

and should be like this: Can anyone help me out, please?

Can anyone help me out, please?already in the formulas of kf I found that in a norm the radiants and other degrees are used.... Who knows that's something trivial. . .

other formula provides me y1=0,418 but still we are not:

Of course, for geometry, I'm using agma-908-b89, but it's not that I'm getting out of it a lot.

Of course, for geometry, I'm using agma-908-b89, but it's not that I'm getting out of it a lot.