thank you, in fact I was told by an engineer quite old mold.... other question: I looked at straight teeth wheels, helicals and worms without end, but I saw that there are so many other types, besides the conical ones which I would like to look at?

If you are not going to put yourself in a company that only manufactures gears, I would say that to leave, there is enough if you consider:

- cylindrical wheels straight teeth (helicoidal with \( \( \0 \)) and helical, as well as inner wheels

- straight tooth conical wheels (\( \beta=0 \))

- endless screw and helical wheel

then as applications, I would say it should be analyzed:

- parallel axis gearboxes in line

- parallel coaxial axes (same interax for several stages)

- epicycloidal gearboxes (to straight teeth \( \beta=0 \))

- pingone and cremagleira teeth straight and helical

then when you have mastered the thing, you can push yourself on things a little more evolved, but keep in mind that if a tomorrow I really do, you would go to use specialized computing programs like kisssoft.

I can tell you that in the steel/metalmechanical field, where big machines for medium/heavy processing are built, many parallel axle reducers and some endless screws are used. It's true that you normally buy already made, but it's also true that in some cases you design the reducer (empty for timing, you want because the machine is really special, you want for particular dimensions, you want for containment costs....), so you still need a certain ability to calculation and analysis.

Another important thing is the bearing speech and therefore loads that develop on the trees. the skf manuals that I mentioned several times there are in pdf free on the site and are very useful to address and then to develop the speech of the loads.

look for example

This is what discussion and you will find different ideas.

check the various discussions on the gearboxes. every year we have students who need support and so we try to give them everything you need.

in reference to gear images:

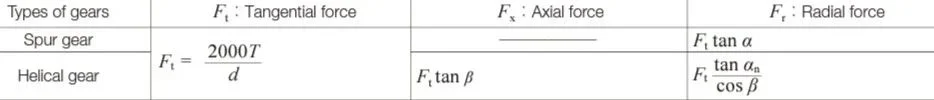

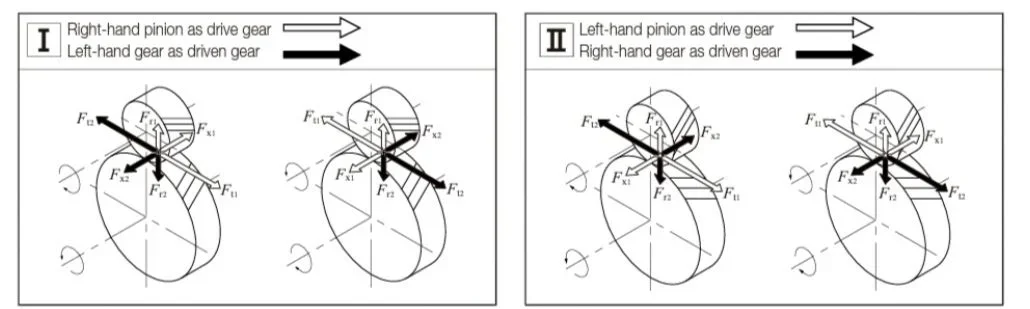

in reference to gear images: as usual the forces are calculated on the application point belonging to the primitive diameter (which is the circumference where the rooms are as wide as the teeth) even if it is not the real one of ingraining. Moreover the pressure angle on the primitive diameter is 20° while on the primitive diameter of operation does not have the same value. it is assumed that behavior is almost identical and therefore the classic primitive is used.

as usual the forces are calculated on the application point belonging to the primitive diameter (which is the circumference where the rooms are as wide as the teeth) even if it is not the real one of ingraining. Moreover the pressure angle on the primitive diameter is 20° while on the primitive diameter of operation does not have the same value. it is assumed that behavior is almost identical and therefore the classic primitive is used.