Hybrid

Guest

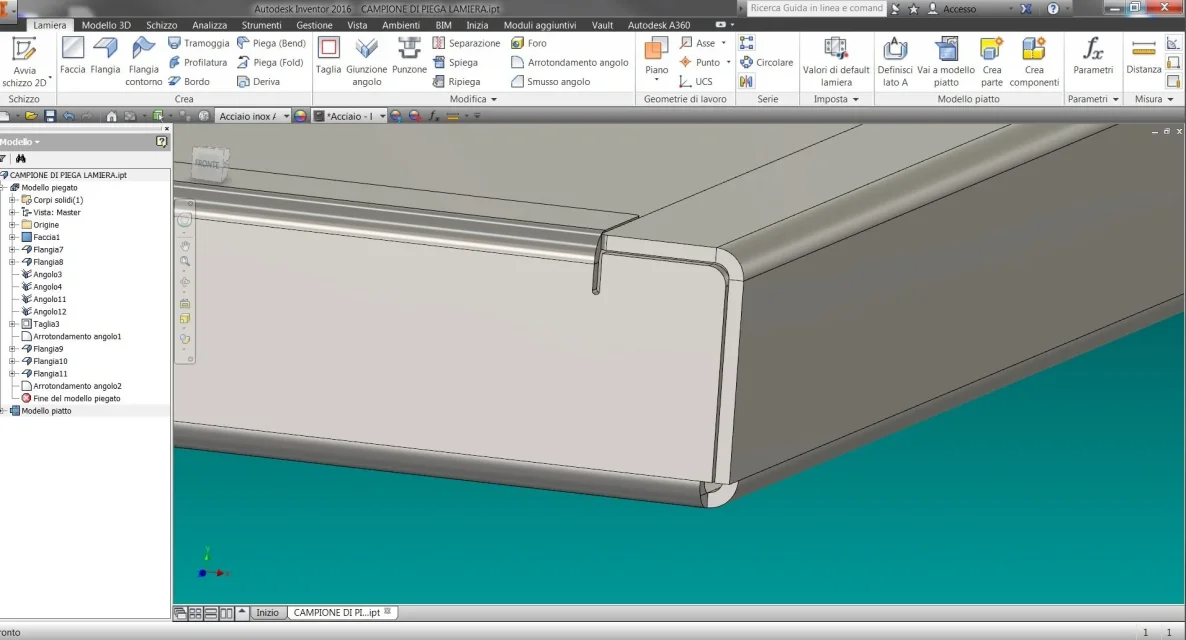

Good morning, everyone! I need a hand to properly develop the attached project. Is there a way to do it with inventor 2016? solid edge had the command to bend to diamond, in inventor I do not see it; but above all I need the correct material to then cut it to the laser and fold the 4 corners. being a liquid tank, the waste must be up to 0.4 mmView attachment test sviluppo lamiera Z508162.dwg