stevio

Guest

Good evening to all,

cause change of work I am approaching the field of sheet metal molds, I am a mechanical designer and for a long time we always discuss with regard to the table masses of the various plates of a mold, platelets, door matrices, hat, base, etc. etc.

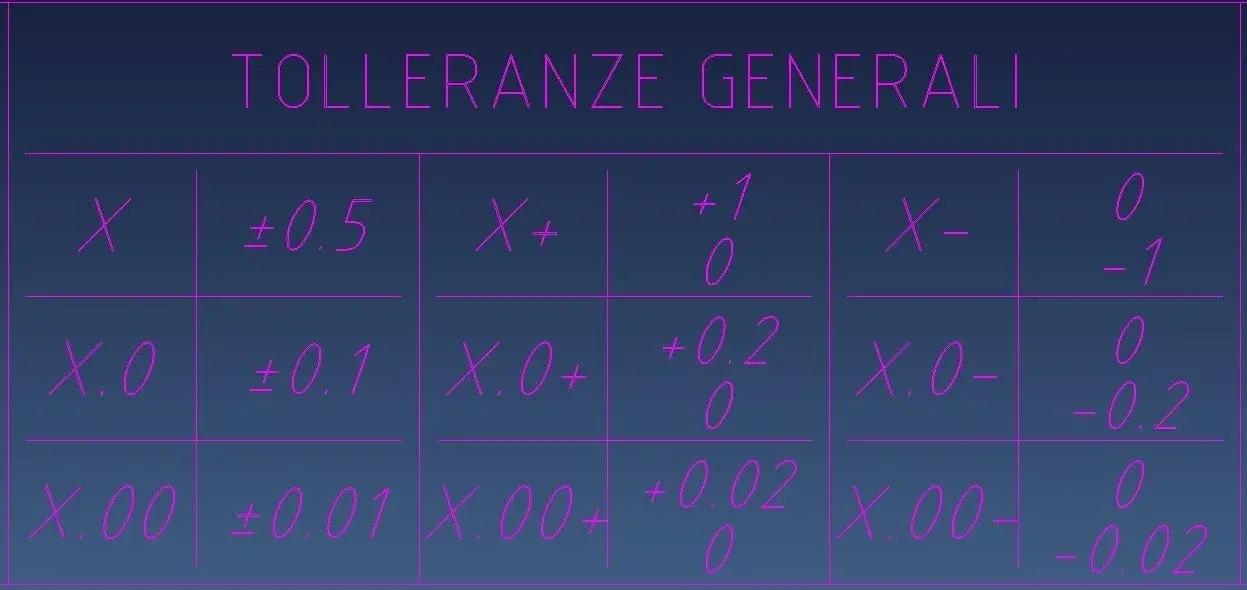

The annexed table for general tolerances is shown on the cartilages of our designs. I press that I never see it, on the vademecum is absolutely not mentioned.

Is there someone who uses it and who can give me an interpretation?

Thank you.

cause change of work I am approaching the field of sheet metal molds, I am a mechanical designer and for a long time we always discuss with regard to the table masses of the various plates of a mold, platelets, door matrices, hat, base, etc. etc.

The annexed table for general tolerances is shown on the cartilages of our designs. I press that I never see it, on the vademecum is absolutely not mentioned.

Is there someone who uses it and who can give me an interpretation?

Thank you.