Soffio

Guest

Good morning.

I'm here to ask for help.

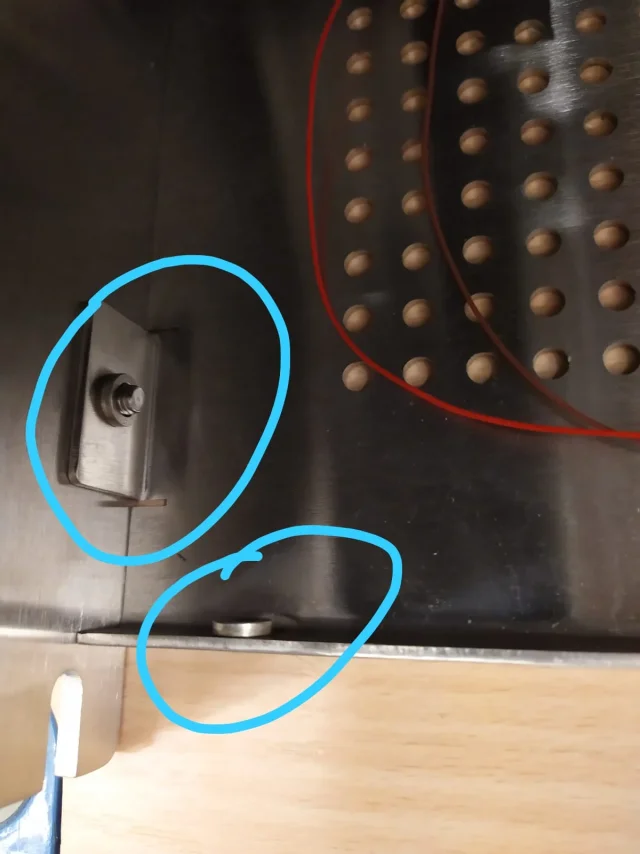

I should produce a sheet metal box (of 1.5mm thickness), the fixing between the various pieces that make up the box will happen by means of screws. given the reduced thickness of the sheet, it is difficult to make a thread.

My question is: what they call and where could I find inserts that allow me to fix the pieces between them?

I happen to see something similar to what I'm talking about (in the annex)

thanks in advance

I'm here to ask for help.

I should produce a sheet metal box (of 1.5mm thickness), the fixing between the various pieces that make up the box will happen by means of screws. given the reduced thickness of the sheet, it is difficult to make a thread.

My question is: what they call and where could I find inserts that allow me to fix the pieces between them?

I happen to see something similar to what I'm talking about (in the annex)

thanks in advance