jno

Guest

I'm sorry, I asked you a stupid question.

It was enough to read more carefully what you have already written to me.

you used spaceclaim and saved file is not editable by designspark

for some reason we don't know.

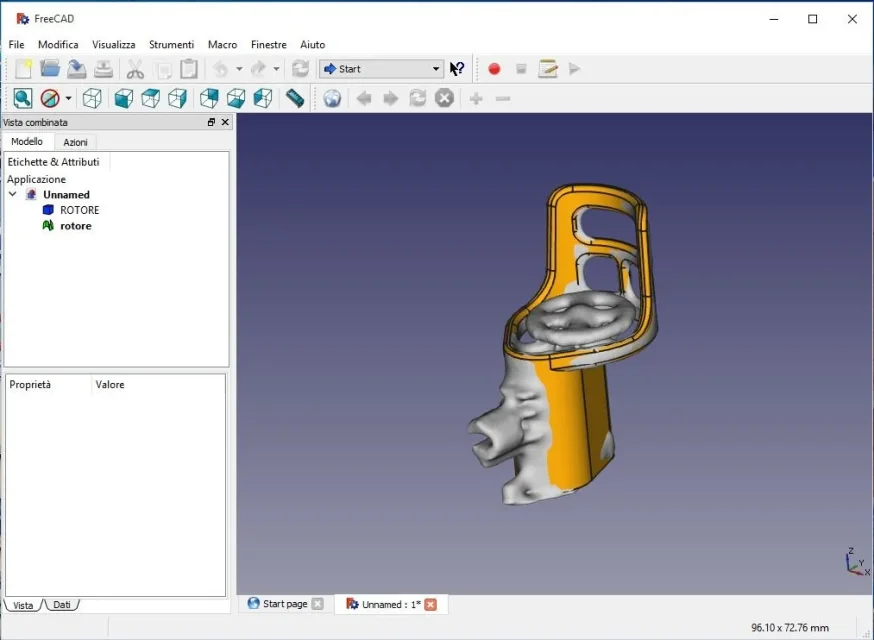

a question, you covered the stl file and the drive hole that is 7.2 mm is 9.2 mm.

this means that you lose original measurements using a stl file in general,

or that since I posted the simplified version

of the stl file to fit the forum size

is this simplification that varies the quotas of the various components the plastic block?

i.e., using the original stl file, would the odds be more consistent with the scanned model?

It was enough to read more carefully what you have already written to me.

you used spaceclaim and saved file is not editable by designspark

for some reason we don't know.

a question, you covered the stl file and the drive hole that is 7.2 mm is 9.2 mm.

this means that you lose original measurements using a stl file in general,

or that since I posted the simplified version

of the stl file to fit the forum size

is this simplification that varies the quotas of the various components the plastic block?

i.e., using the original stl file, would the odds be more consistent with the scanned model?