GIOVANNI682

Guest

Good morning.

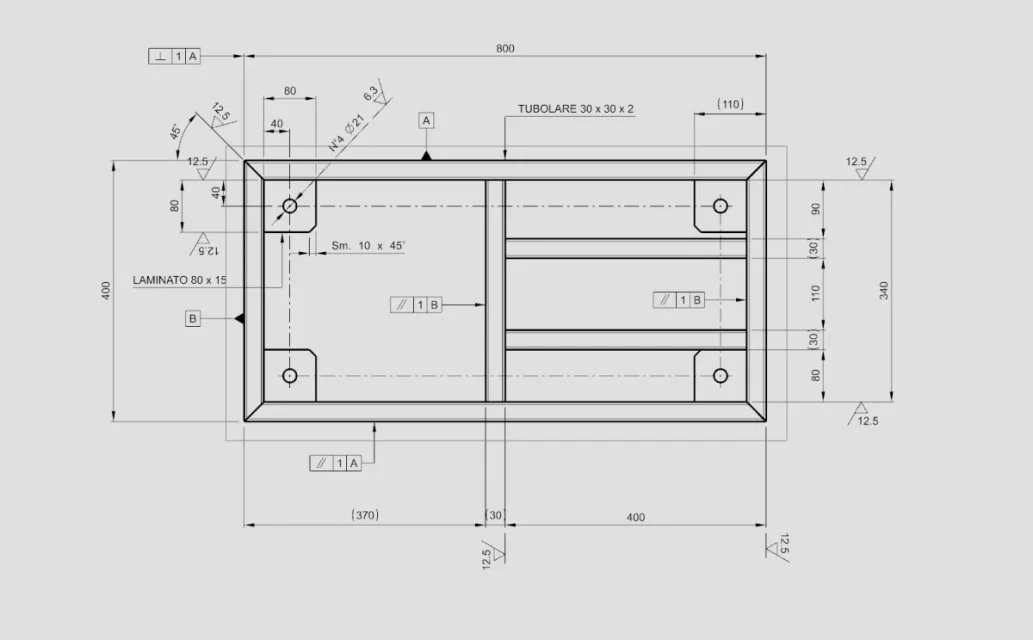

I would like to ask for an opinion on the table of a frame.(like if I have to indicate and angles on all cuts with wrinkles, geometric tolerances, altitude position...etc)

I have only a view because I am preceding in the same way with the other views.

I don't have any doubts, but I'm interested in how you can share welded frames so you can improve.

thanks in advance

I would like to ask for an opinion on the table of a frame.(like if I have to indicate and angles on all cuts with wrinkles, geometric tolerances, altitude position...etc)

I have only a view because I am preceding in the same way with the other views.

I don't have any doubts, but I'm interested in how you can share welded frames so you can improve.

thanks in advance