You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

MassiVonWeizen

Guest

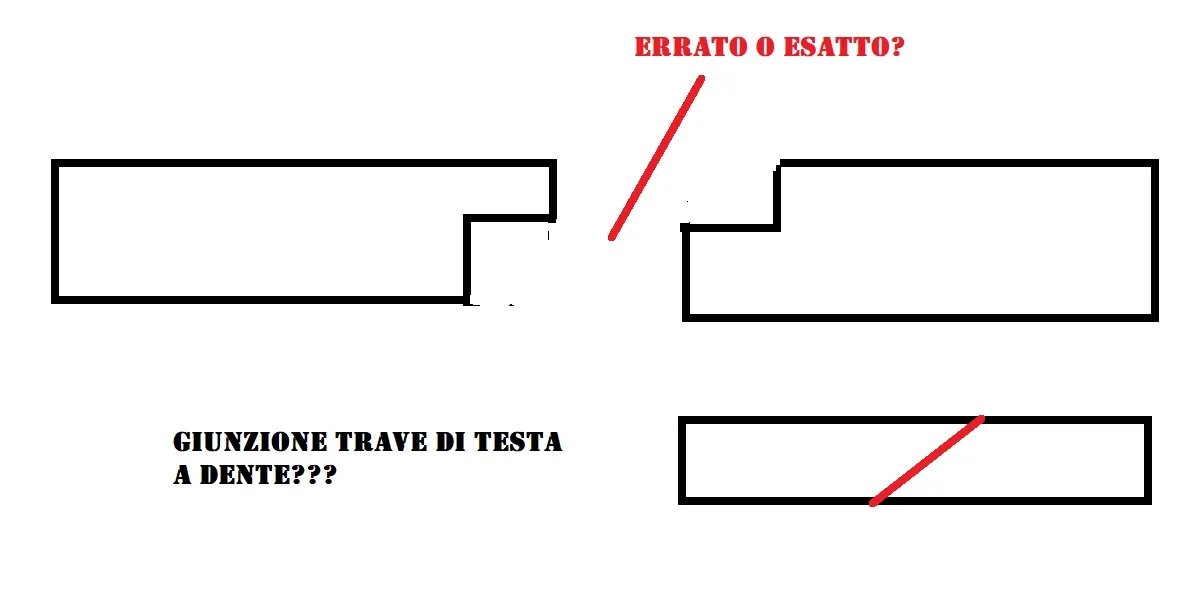

continuity makes the quality of welding; the type of joint helps in the type of function that has the beam

Marco F inox

Guest

when welding, the weakest part always turns out to the two sides of the cord, where the material is not affected by the welding but heats enormously, receives as annealing.

in the welding of large beams, it must be avoided as much as possible that this area is on a single cross section of the beam, because it would make it more yieldable.

in the design that you placed it would be good to fade, but the two chinas are missing.

it would be better and very practical with the seghetto make the two cuts as in the second figure, then get the cyanfrines, of appropriate width, cutting the two tips always with the same inclination.

the central part of the beam will not be affected by welding, but it is also the least stressed.

in the welding of large beams, it must be avoided as much as possible that this area is on a single cross section of the beam, because it would make it more yieldable.

in the design that you placed it would be good to fade, but the two chinas are missing.

it would be better and very practical with the seghetto make the two cuts as in the second figure, then get the cyanfrines, of appropriate width, cutting the two tips always with the same inclination.

the central part of the beam will not be affected by welding, but it is also the least stressed.

saldocarpentiere

Guest

thanks for clarification, you would be so kind to insert the best method with all the procedure, cyanfrino corners and everything I need, thank you excuse me if I take advantage of your precious time.

Marco F inox

Guest

the opening and welding of the double t beam design, fine.

if, however, the external surfaces must be smoothed evenly, it is necessary to make the bevels on the two lembies, to make the welding material penetrate as much as possible.

there are three basic types of cianphrine, where it is always necessary to leave a few millimeters of frontal flat surface, to support the fusion bath and at the same time ensure complete penetration:

a v, where the two bevels are made only on the upper surface, with a maximum angle of 45°.

a x, where four bevels are performed, two above and two below, with a maximum angle of 45°.

a u, where the two bevels, performed only on the upper side, are radiated and form a u.

with all these cianfrinatures on the big thicknesses, you can and you must obtain complete continuity of the material, because the welding of carry, not only fills, but protrudes both above and below.

if, however, the external surfaces must be smoothed evenly, it is necessary to make the bevels on the two lembies, to make the welding material penetrate as much as possible.

there are three basic types of cianphrine, where it is always necessary to leave a few millimeters of frontal flat surface, to support the fusion bath and at the same time ensure complete penetration:

a v, where the two bevels are made only on the upper surface, with a maximum angle of 45°.

a x, where four bevels are performed, two above and two below, with a maximum angle of 45°.

a u, where the two bevels, performed only on the upper side, are radiated and form a u.

with all these cianfrinatures on the big thicknesses, you can and you must obtain complete continuity of the material, because the welding of carry, not only fills, but protrudes both above and below.

saldocarpentiere

Guest

thanks x the answer greetings., ps would go reinforcements, like membrature handkerchiefs plates etc., what would be expected?

MassiVonWeizen

Guest

Progettare in acciaio - Fondazione Promozione Acciaio

L'Ufficio Tecnico di Fondazione Promozione Acciaio, con lo scopo di fornire aggiornamenti costanti alle figure che operano nel settore delle costruzioni come progettisti, direttori dei lavori, centri di trasformazione, costruttori metallici, ecc, presenta una serie di guide tecniche e software

biz

Guest

depends on the forces at stake.there would be reinforcements, like mixes handkerchiefs plates etc., what would be expected?

even bevels depend on the forces at stake.

are decisions that belong to the designer.

saldocarpentiere

Guest

thanks for the exhaustive clarification. greetings