ansyolitico

Guest

Hello everyone

I think I'm losing in a glass of water.

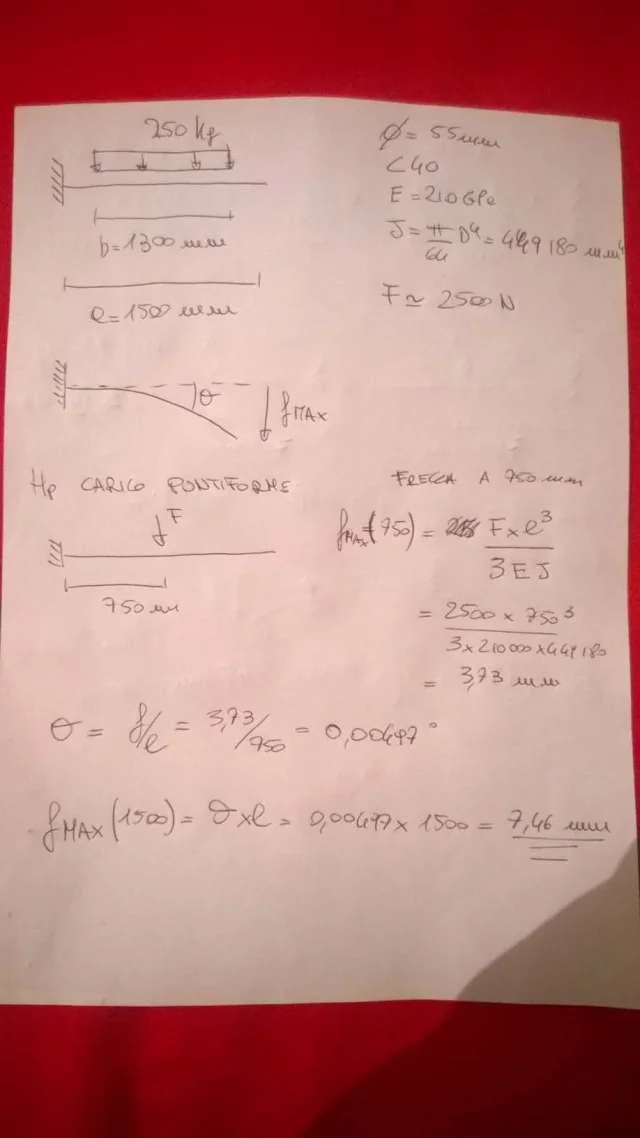

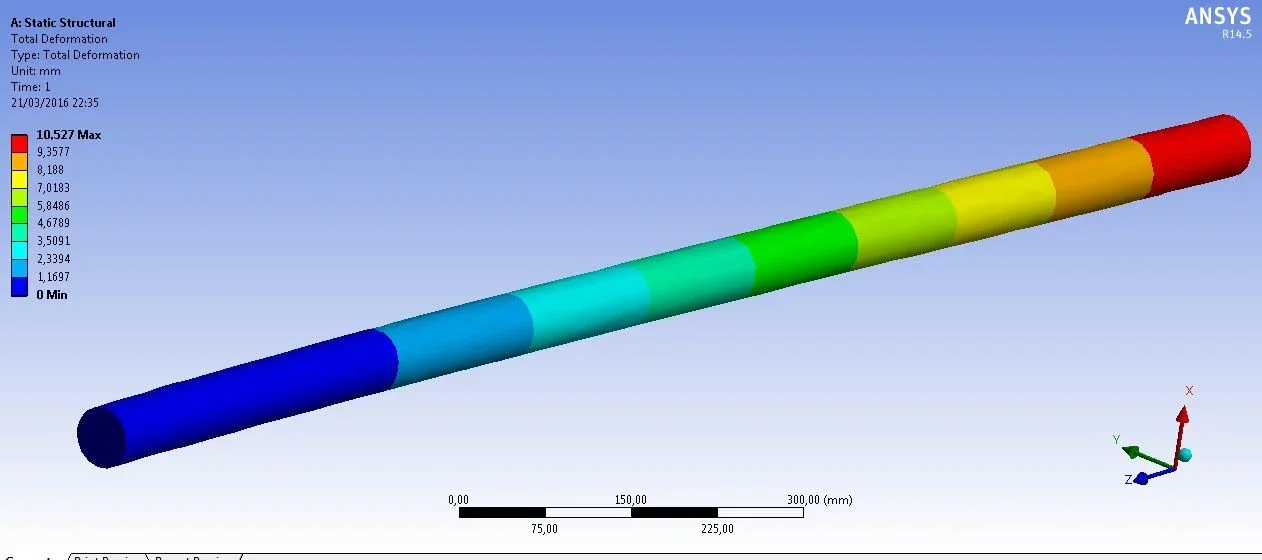

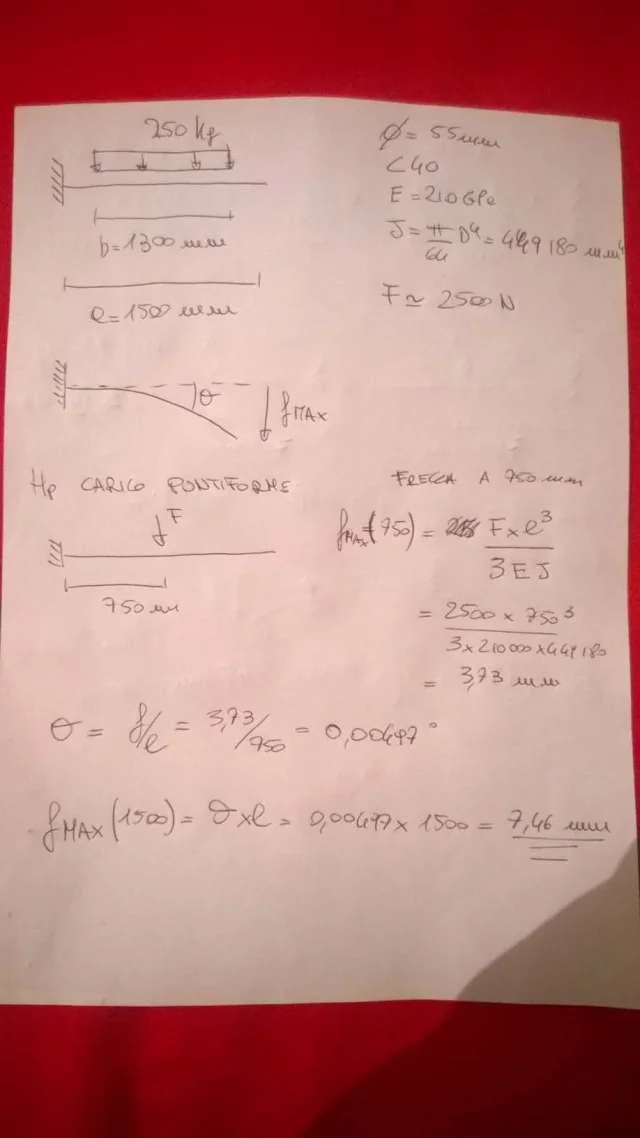

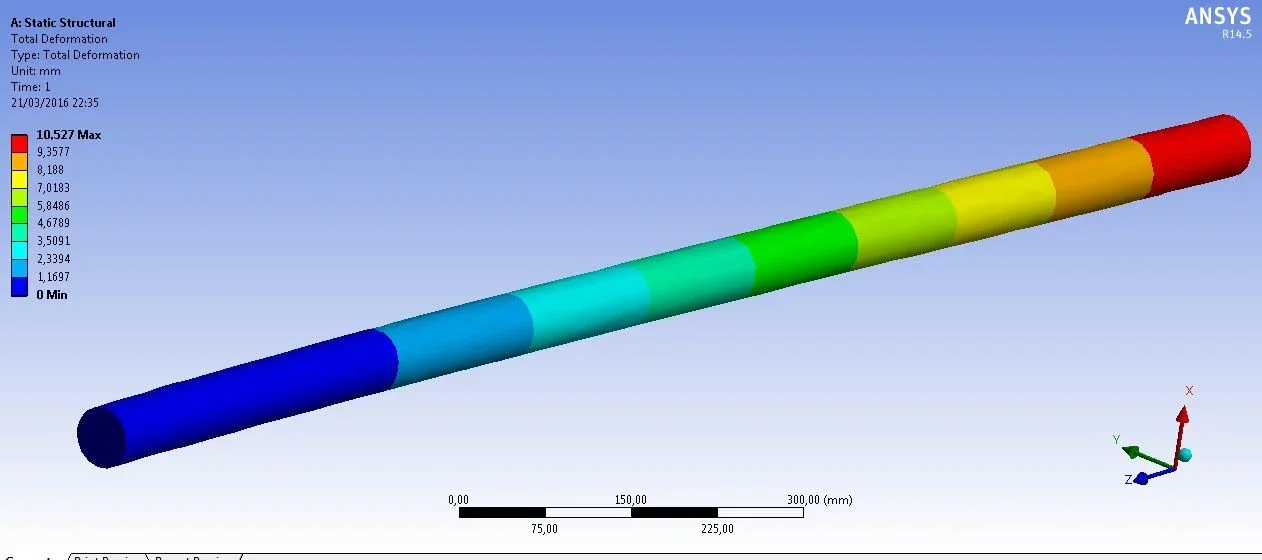

I have a simple round beam diameter 55 with a distributed load as from drawing....using the classic forms of structural mechanics I have a max arrow of 7.45 mm while with ansys I get a max arrow of about 10... in the analytical calculation I did not take into account the deformation of cut, only of the moment but there is almost a error of 40%...it seems a little too much for a neglect of the cut, besides everything I hypothesized dot load (to be on the side of the reason), so it should be increased, instead of it is minor, someone would know where I would be wrong?

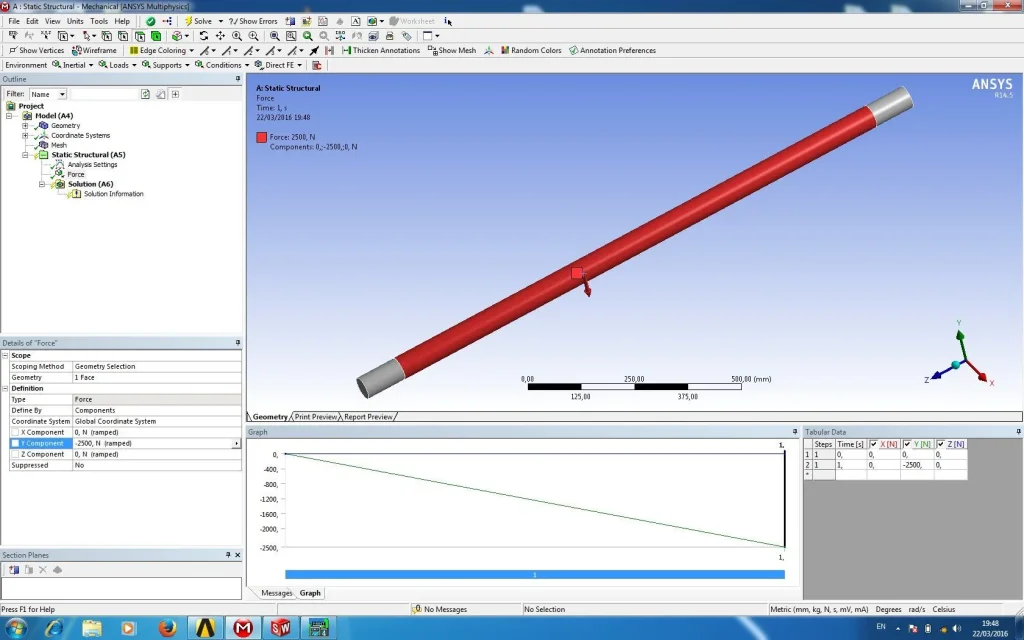

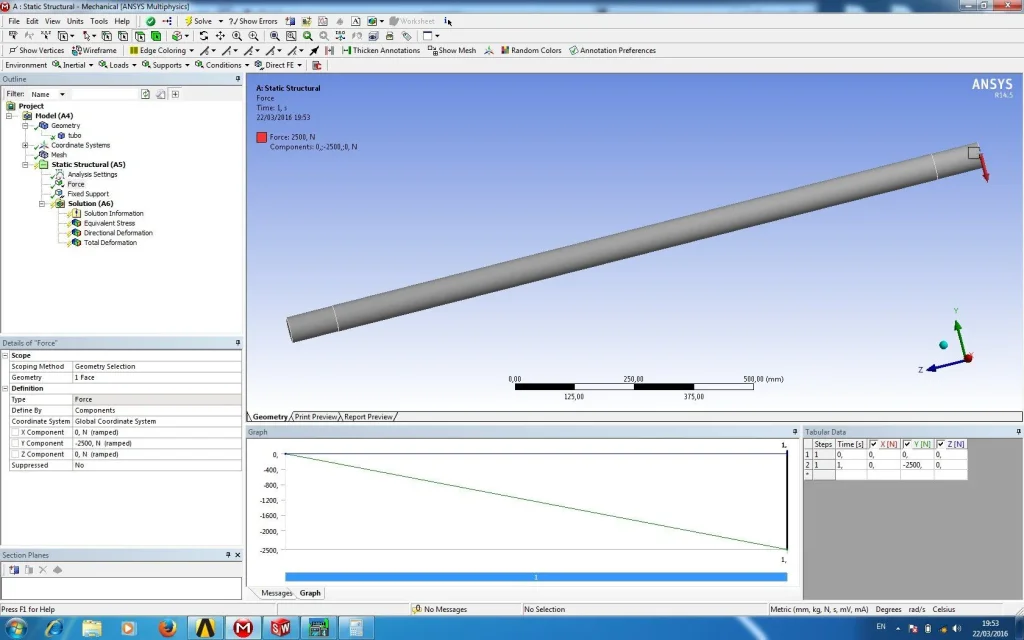

in ansys I put as fixed bond to the extreme of the bar and the load with vector component -2500n on the face of the bar (I extruded previously by increasing a 1 mm diameter to define well the load surface)

on the face of the bar (I extruded previously by increasing a 1 mm diameter to define well the load surface)

I think I'm losing in a glass of water.

I have a simple round beam diameter 55 with a distributed load as from drawing....using the classic forms of structural mechanics I have a max arrow of 7.45 mm while with ansys I get a max arrow of about 10... in the analytical calculation I did not take into account the deformation of cut, only of the moment but there is almost a error of 40%...it seems a little too much for a neglect of the cut, besides everything I hypothesized dot load (to be on the side of the reason), so it should be increased, instead of it is minor, someone would know where I would be wrong?

in ansys I put as fixed bond to the extreme of the bar and the load with vector component -2500n