Join the forum for Designers!

Your expertise is vital to the community. Join us and contribute your knowledge!

Join the Forum NowShare, learn and grow with the best professionals in the industry.

The Winged Victory or Nike of Samothrace is a statue prominently featured in The Louvre Museum in Paris, France. Mastercam recently teamed up with YASDA Precision, Mitsubishi Materials, and Methods Machine Tools to create an 11-inch replication of the famed 18-foot statue.

Within Mastercam, the statue is a mesh file with over five million facets and was 10 gigabytes in size. Mastercam took the part from a raw piece of stock all the way to a finished part. “I have never made a part of this caliber in my life” said Mastercam Sales Engineer II, Chad Chmura. The overall cycle time on this project was over 110 hours –just under five straight days!

Since this piece was such a large Mastercam file, a series of videos on our YouTube Channel was created to demonstrate the different Mastercam tools used in the making of it, and how those tools are the exact same that you have access to as a Mastercam user.

Here are several highlights of Mastercam features used to create this amazing piece.

Detect Undercut Stock

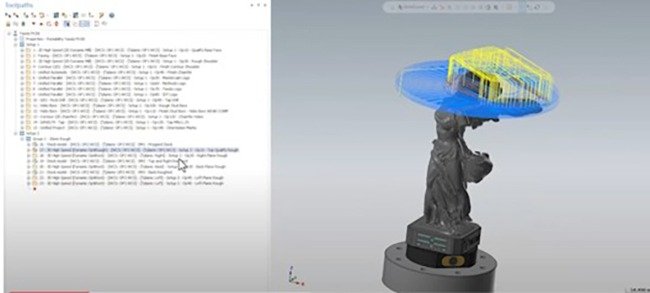

Mastercam’s OptiRough toolpath was used to kickstart the roughing phase of the statue.

In Mastercam 2023, we introduced the Detect Undercut Stock checkbox, which allows the user to trim all of the air cuts with just a single click of a box. By using this feature, the run time of the toolpath was cut by a third from 18 minutes to 12 minutes. The Detect Undercut Stock checkbox was invaluable on the Nike project because this part was full of hidden undercuts.

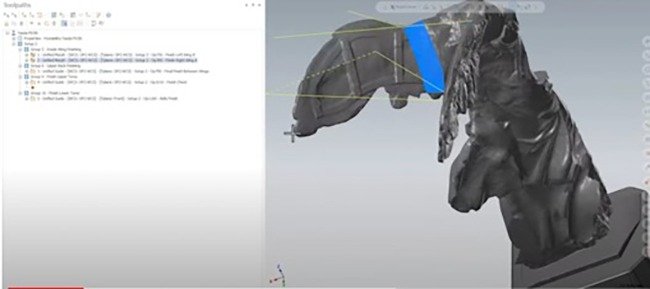

Unified Multiaxis

Mastercam’s Unified Multiaxis toolpath helped finish the Nike statue as it allowed the YASDA machine to make long sweeping motions in several phases of the project, including the wings and the front of the dress. Since the statue was a mesh file, we could create a wireframe on any point of the mesh, so drive curves were created that followed the wrinkles of the dress’s curvature.

Using this as a guide curve in Unified Multiaxis, we could control the step over in a way that followed the exact contour of the dress, which made the step overs of the toolpath blend into the profile of the part.

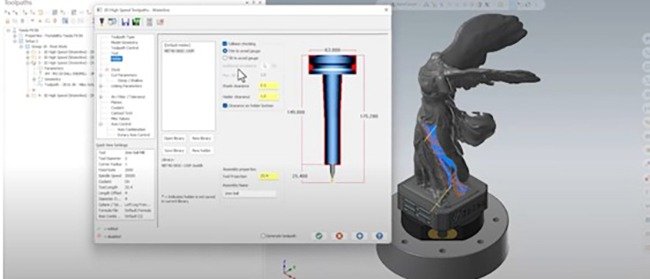

Advanced Holder Checking

When programming a part as complex as the Nike statue, it is crucial to keep our tool and holder safe. Mastercam has the ability to apply holder checking, which means we can trim our toolpath motion or create tilt motion anytime our tool holder will interfere with the part.

While working on the Nike statue, we had to keep our toolpath moving without any collisions. Mastercam’s Check Holder function allows the user to calculate a safe minimum tool projection for all of your Mill toolpaths.

A Special Thanks

The Nike of Samothrace statue is truly an incredible piece we were thrilled to create using Mastercam. The intricacy of the part allowed our engineers to test the limits of Mastercam. We send a very special thanks to our partners YASDA Precision, Methods Machine Tools, 5th Axis, Lyndex-Nikken, and Mitsubishi Materials for their contributions in making it possible.

Join the forum for Designers!

Your expertise is vital to the community. Join us and contribute your knowledge!

Join the Forum NowShare, learn and grow with the best professionals in the industry.