I agree, your solution is the best. :finger:

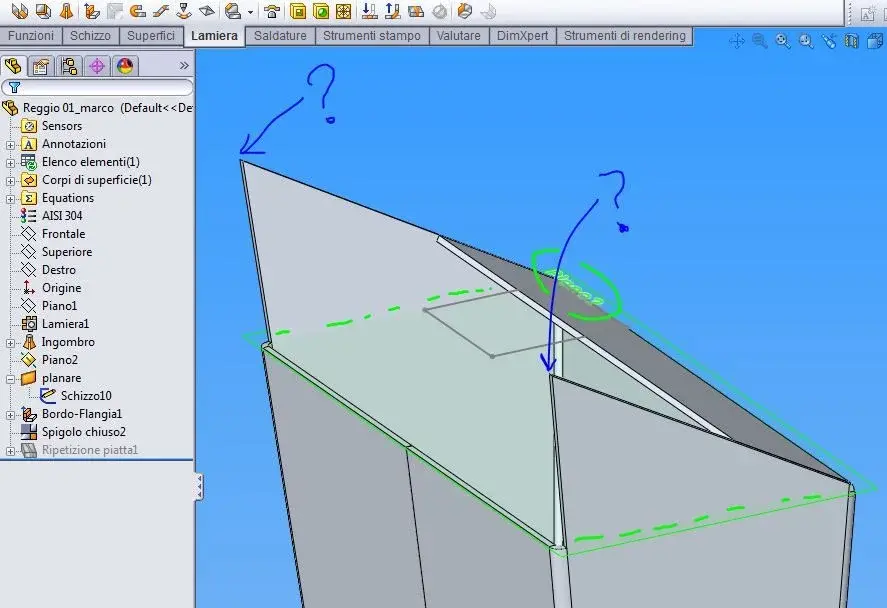

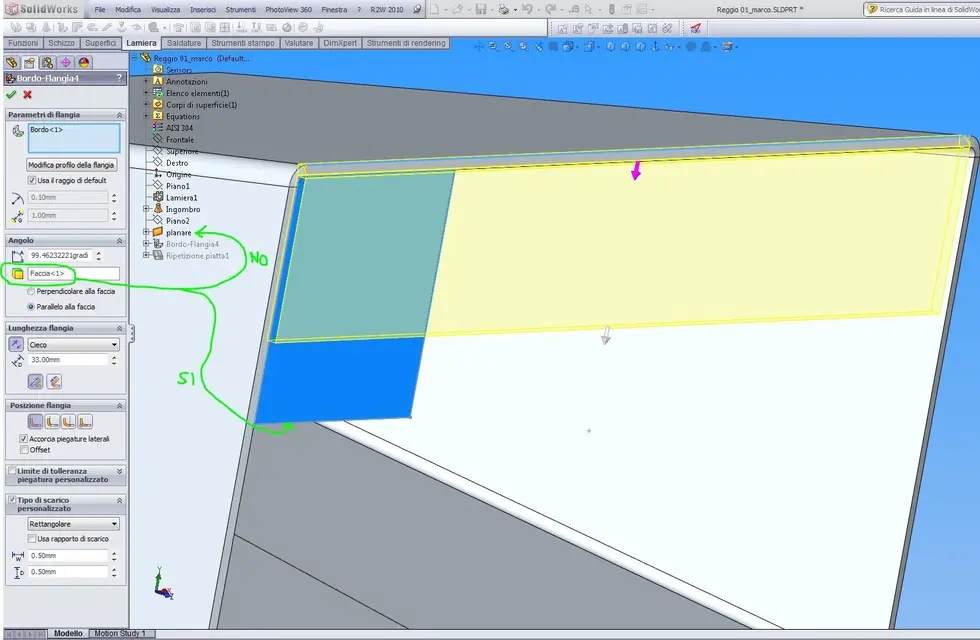

Could you explain to me how you got the fold drain?

I didn't understand how you got it, it looks like an extrusion?

You can help me. :bekle:

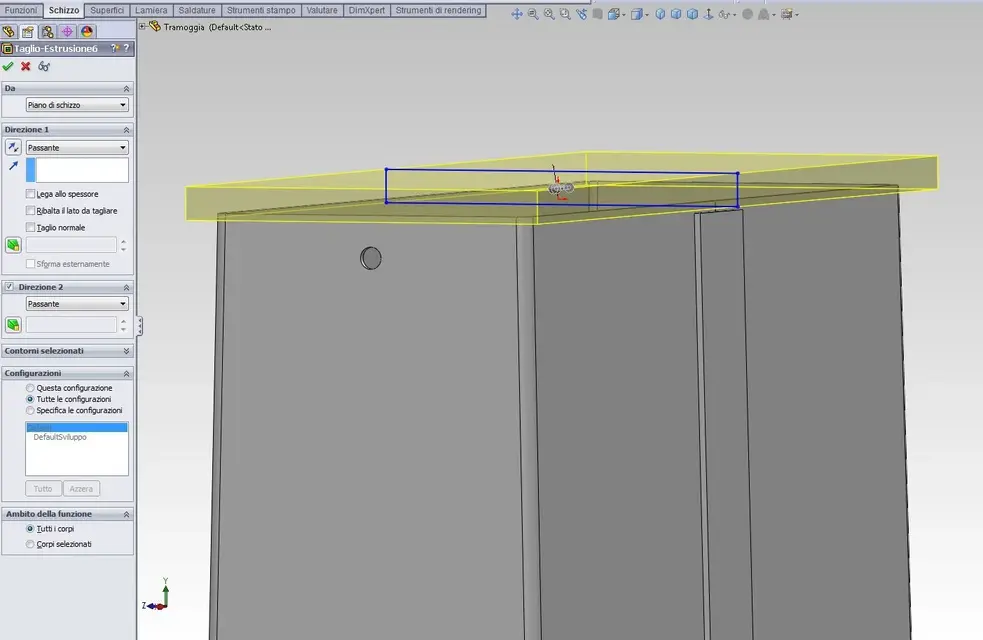

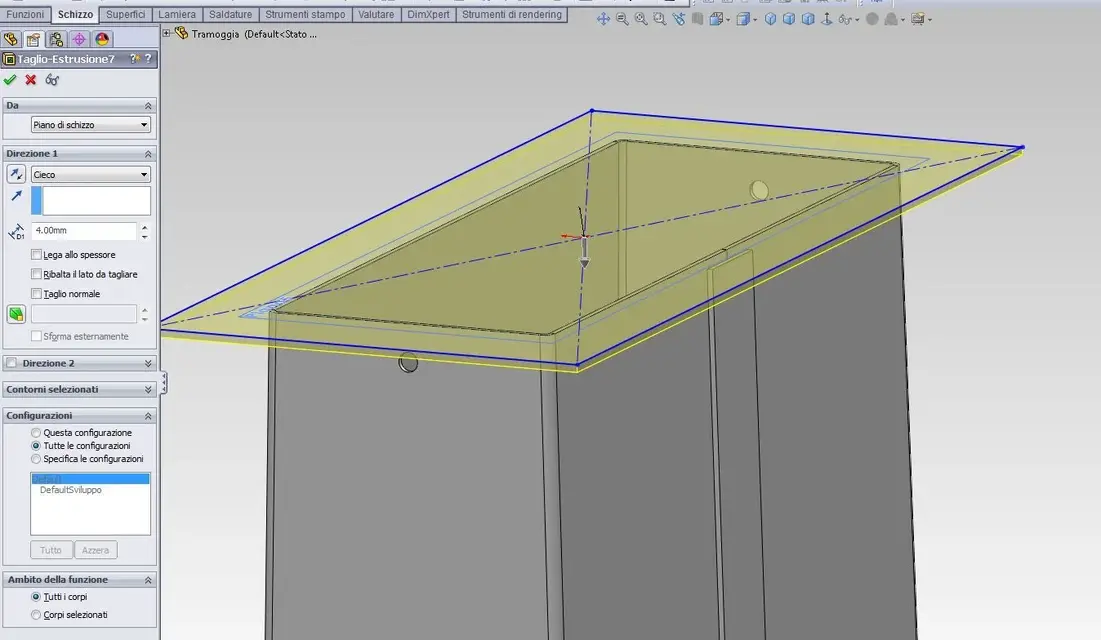

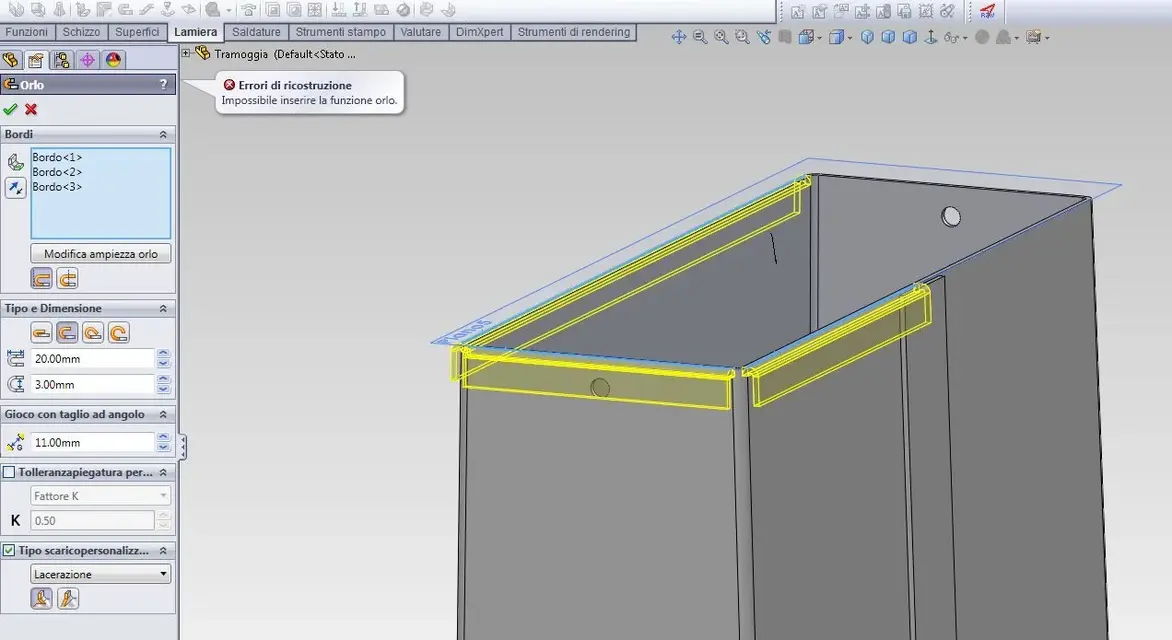

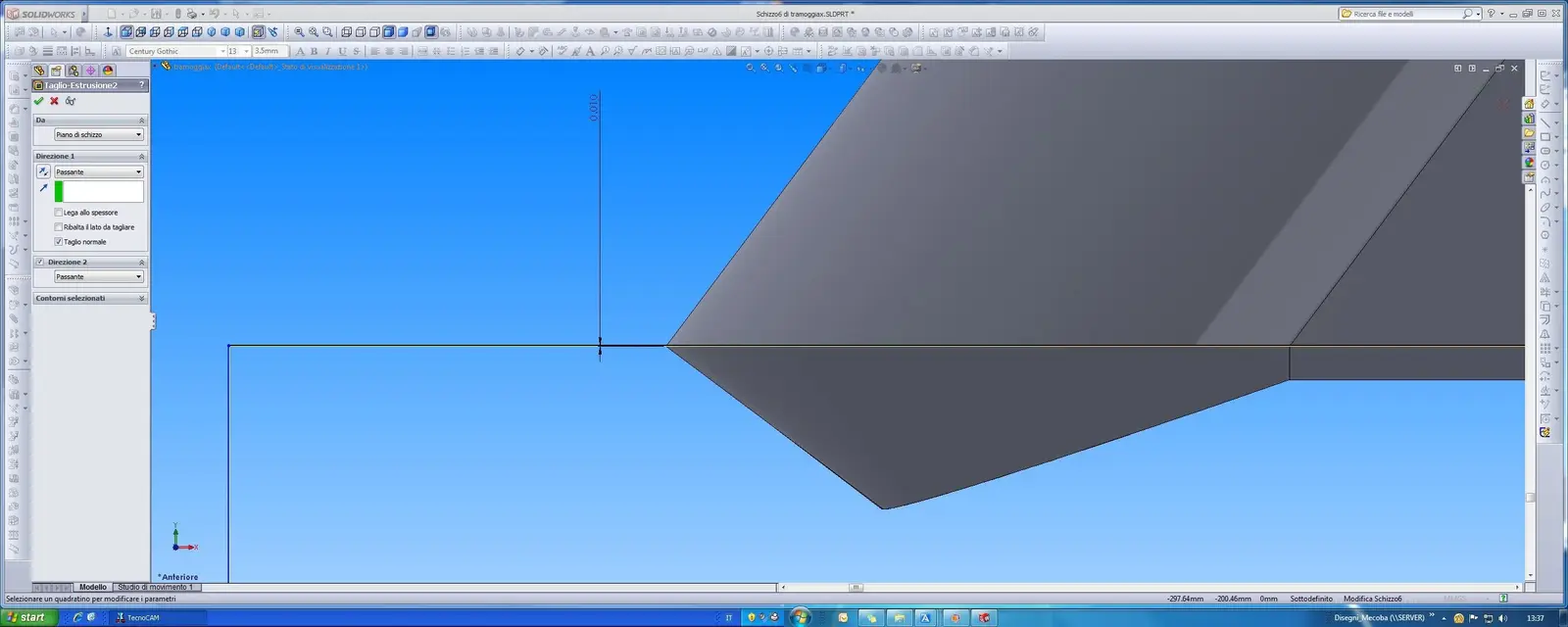

He made an extruded cut. often happens to find problems because swx fails to download a edge, especially when inserting the folds in a solid part obtained by loft.

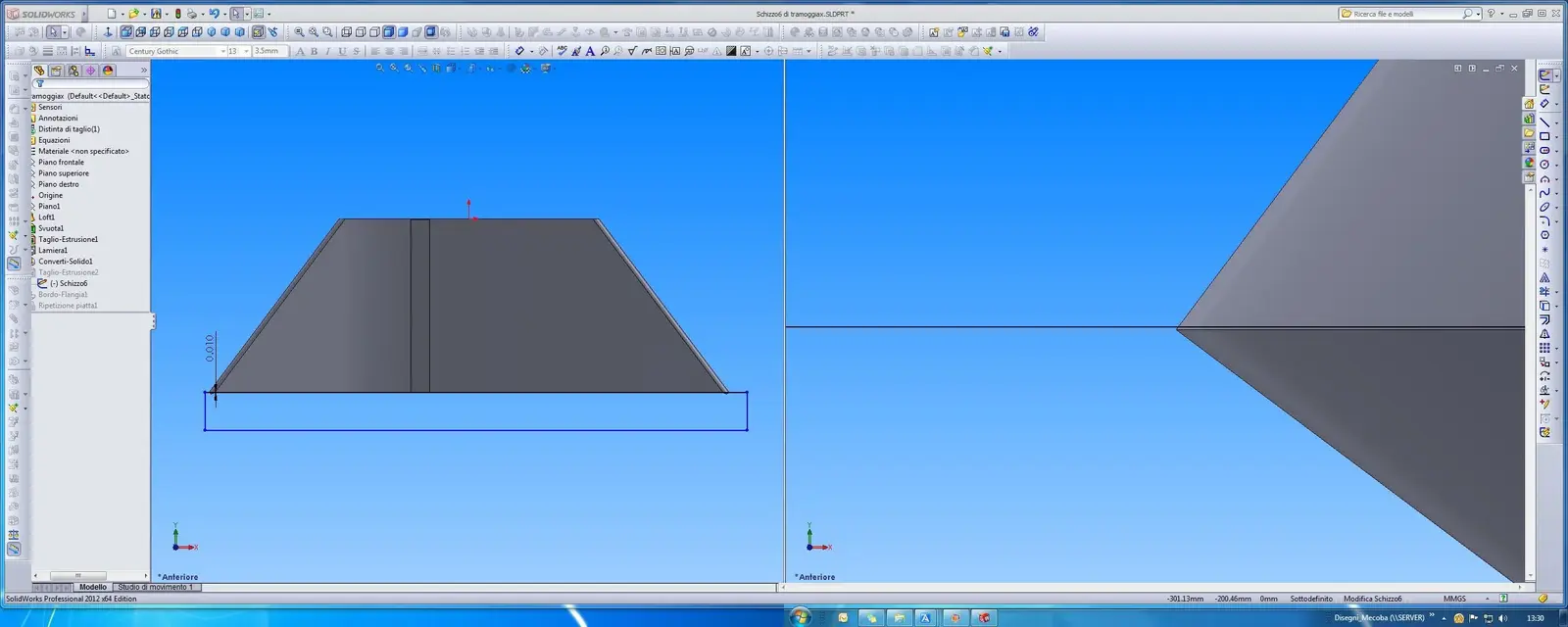

I usually, when it fails development, proceed in this way:

control1: I verify that all faces are actually flat (with solid lofts you have to be careful). to perform this check I click one face at a time and check that there is a chance to make us over a sketch

Control 2: I begin to perform macro cuts in edges at one by one until I find the problematic one. Once I find I delete all the other cuts and I go to shred as much as possible the cut remaining.

mike is right, the sheet is another way of conceiving the cad and also with much experience you often end up in a blind alley and you need to delete the features i restart with another method.

I use a little all the methods:

traditional sheet metal functions

solid functions with bending insert

conversion into solid body sheet

conversion into sheet metal

multibody sheeting

all seasoned by topdown modeling with skeletons.

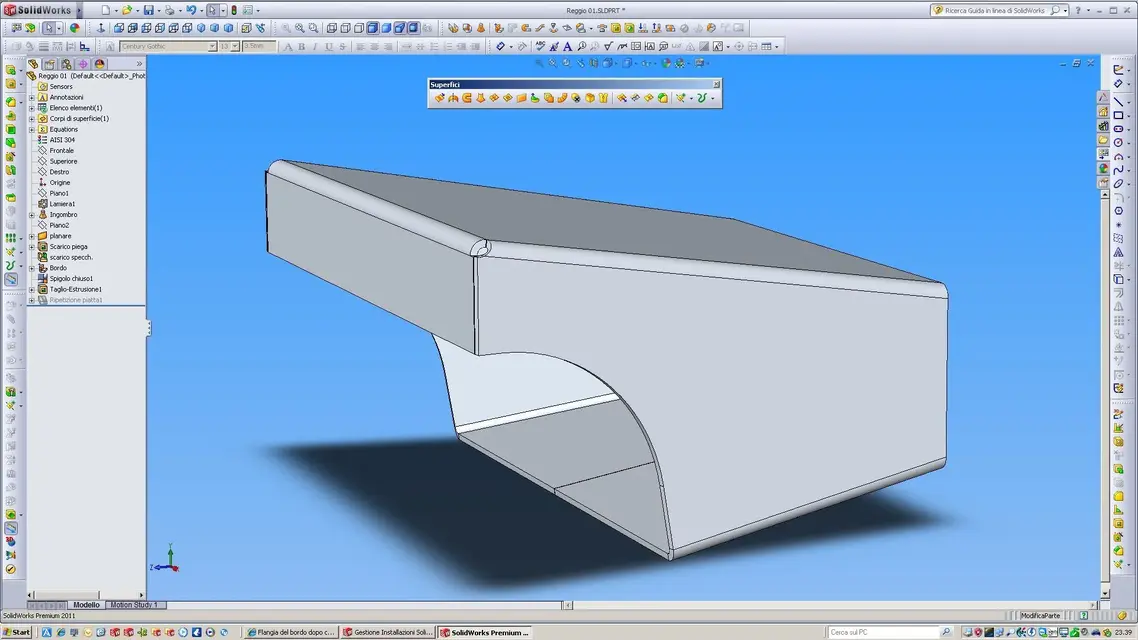

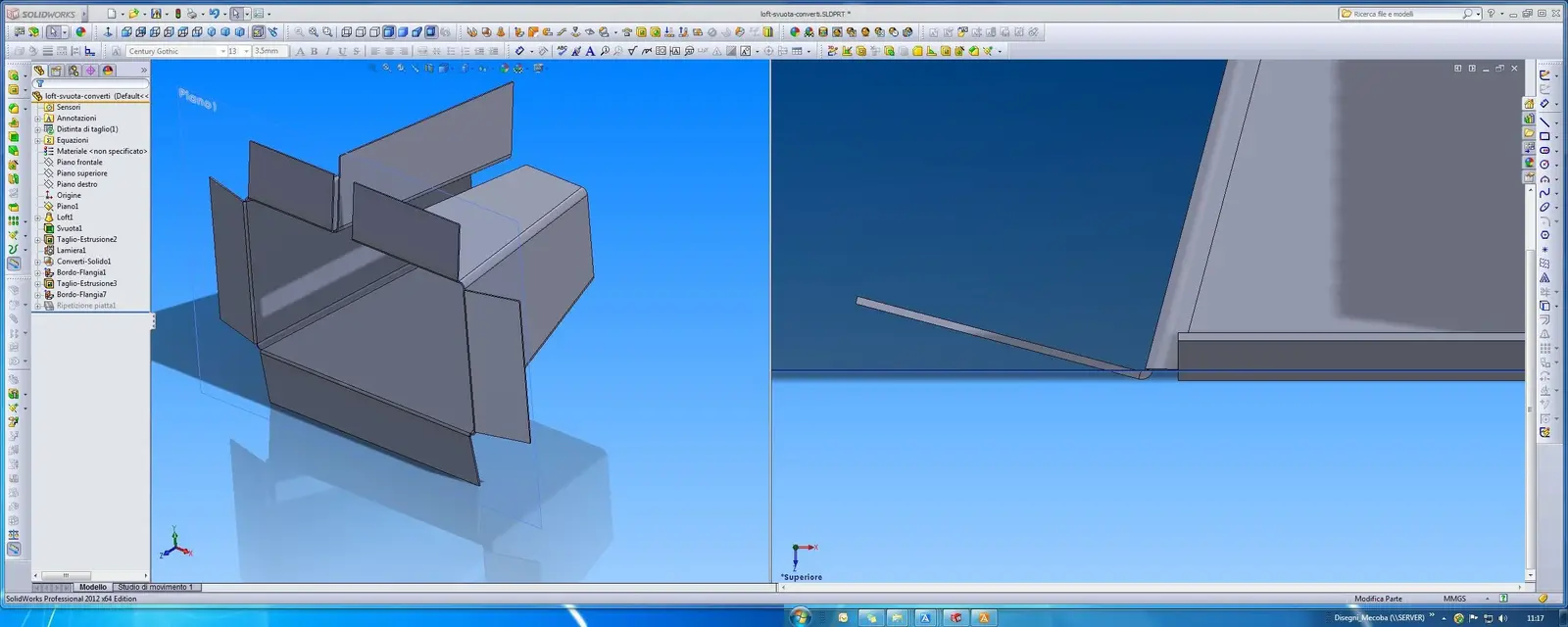

However I attach another solution of the reggio sheet. I point out that in the loft plate solution it takes 1.73 seconds for reconstruction, with the solution I posted 0.50 seconds. my solution also gives the possibility to create a lightened configuration without the functions of sheet metal, in case the reconstruction goes to 0.03 seconds.

If you have to mount it in a complex set I would make a little thought.

good job!!!:finger:

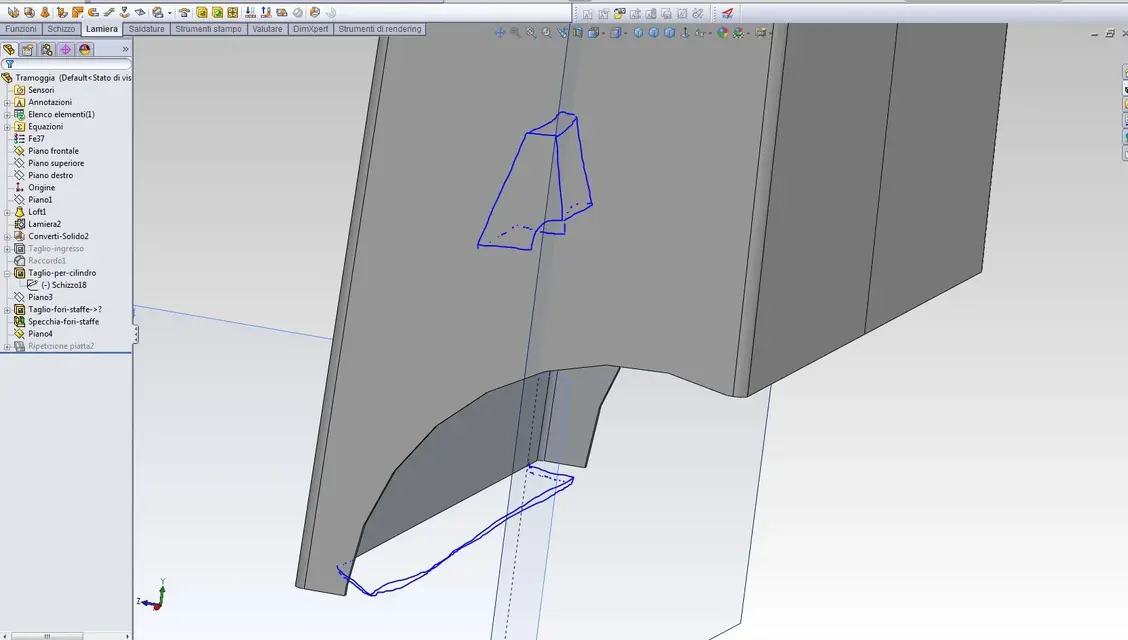

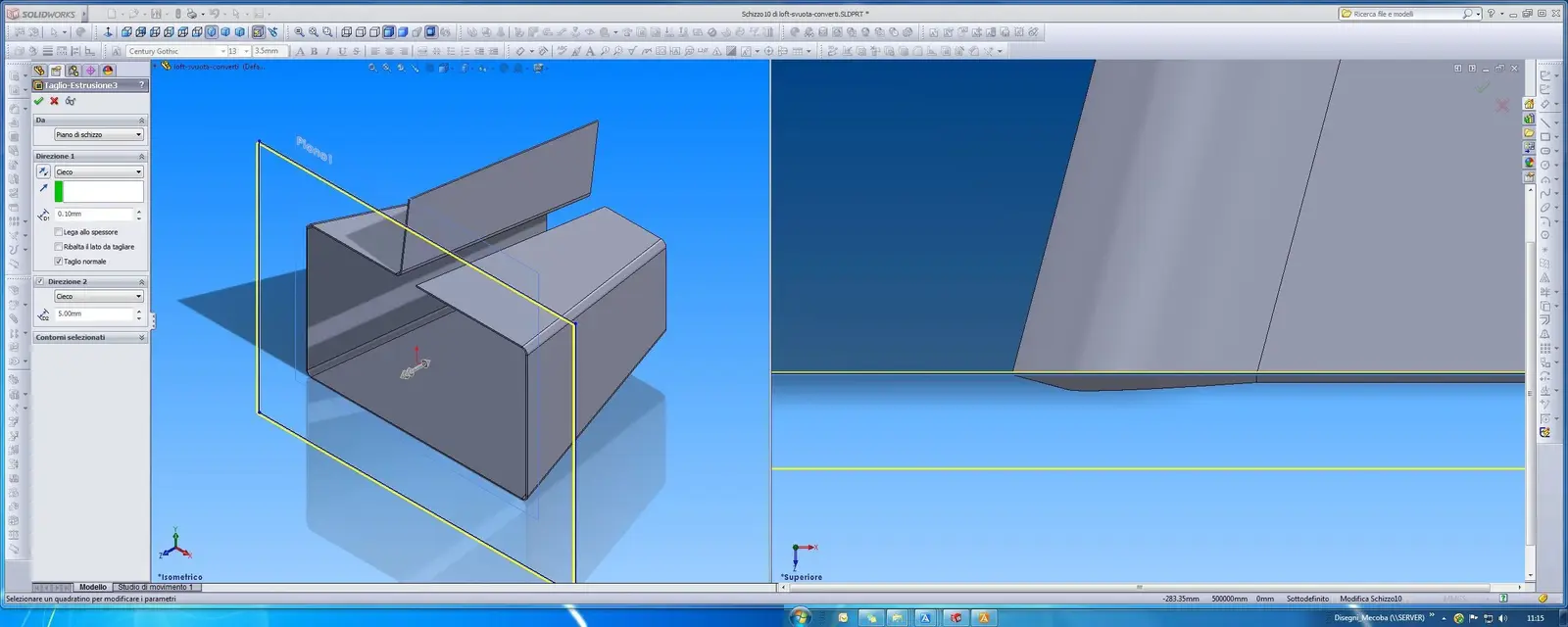

hi, I made a log trapeze that I then converted into sheet metal,

hi, I made a log trapeze that I then converted into sheet metal,