anonto

Guest

Hello everyone,

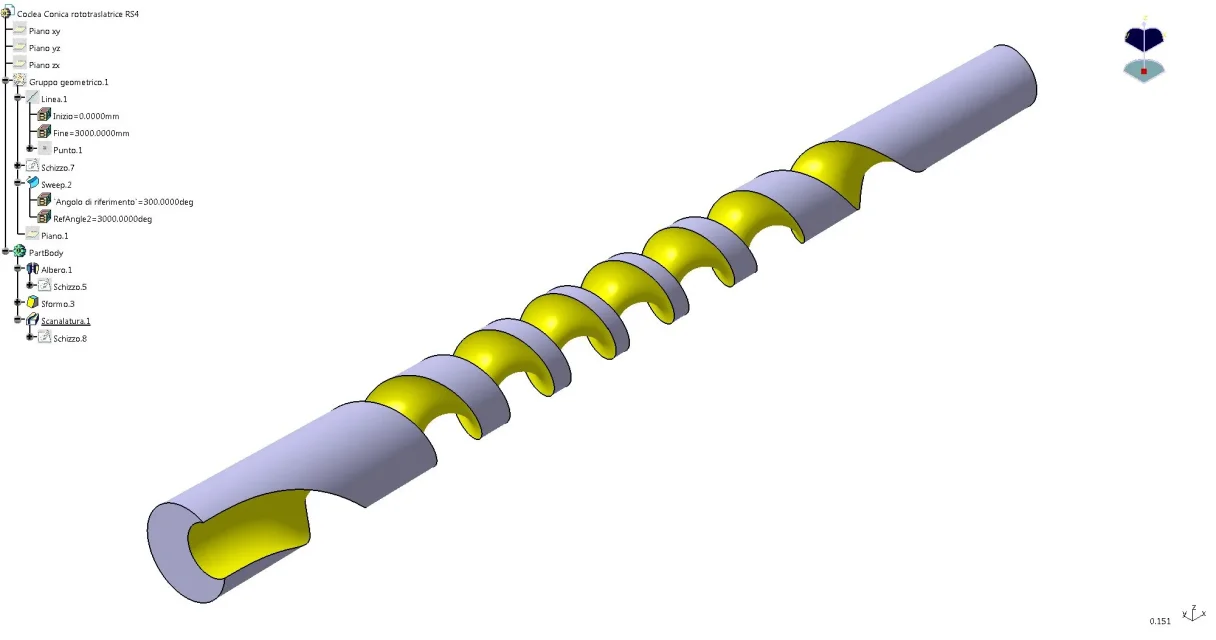

I'm a mechanical engineering student and I'm going to revert a coclee until I get a model I can use for simulations in my graduation.View attachment 378the coclea in question (photo), coupled with his twin (specular), takes the product from a line (right), separates it from the line and rototrasla (also with the help of a lower tape) and finally translates it only (to the left).

the product is a rectangular prism, and enters between the two screws slightly inclined to favor separation

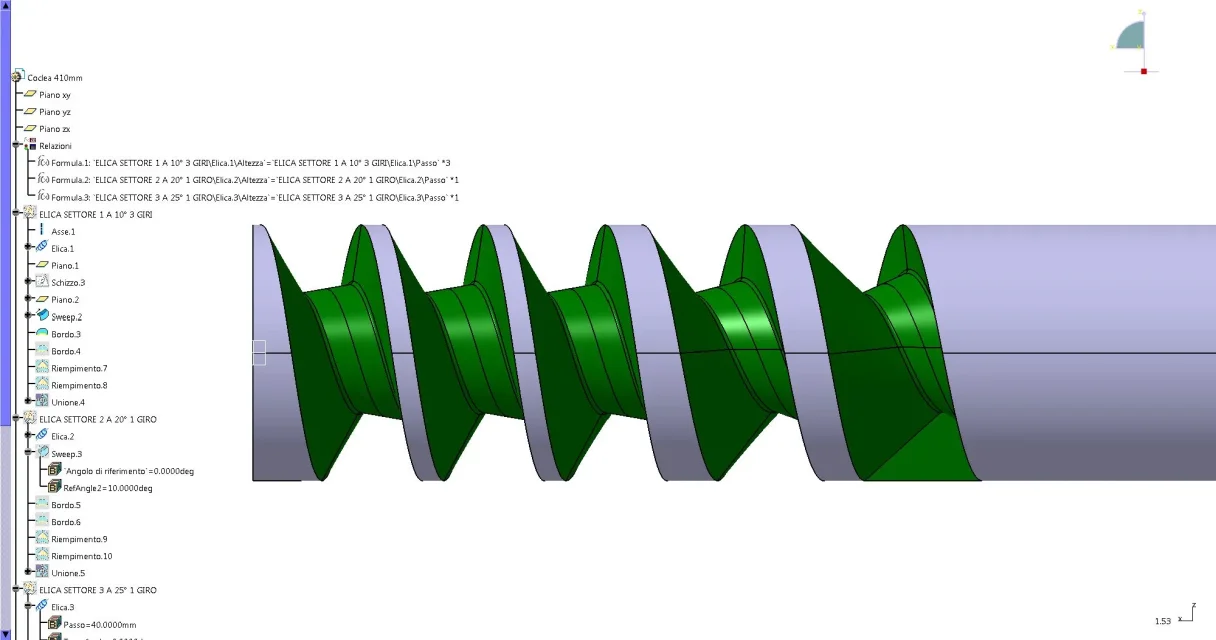

To replicate the piece, I thought I'd split the piece into three parts, the first and the last one more or less managed to do it, not without big doubt and perplexity:

the central part of the auger to rotate the piece I have absolutely no ideas on how to reproduce it.

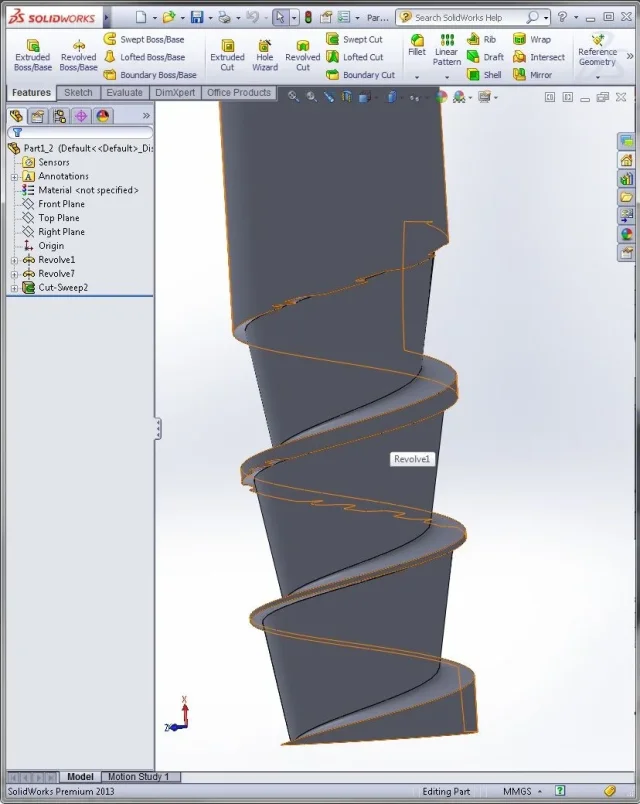

exists a way to tell the tool (solid) that must follow a trajectory along a spiral, but which must also rotate in the meantime?

other questions, but not so serious and/or important, all about the first part of the cochlea:

the cut sweep seems not to go on if after 360 degrees the tool touches the track of the turn before, blocking the cut some degree before (not finishing the revolution then). Is there a way to bypass this limit? the actual coclea has the diameter cut for this reason.

solving the question before, is it possible to give the spiral a growing step without having to give it "discreetly"?

Finally, it is possible to indicate to swx a second direction for the spiral in order to have an extrusion also on the other side to "complete" the coclee?

thanks for any answers

Good day

I'm a mechanical engineering student and I'm going to revert a coclee until I get a model I can use for simulations in my graduation.View attachment 378the coclea in question (photo), coupled with his twin (specular), takes the product from a line (right), separates it from the line and rototrasla (also with the help of a lower tape) and finally translates it only (to the left).

the product is a rectangular prism, and enters between the two screws slightly inclined to favor separation

To replicate the piece, I thought I'd split the piece into three parts, the first and the last one more or less managed to do it, not without big doubt and perplexity:

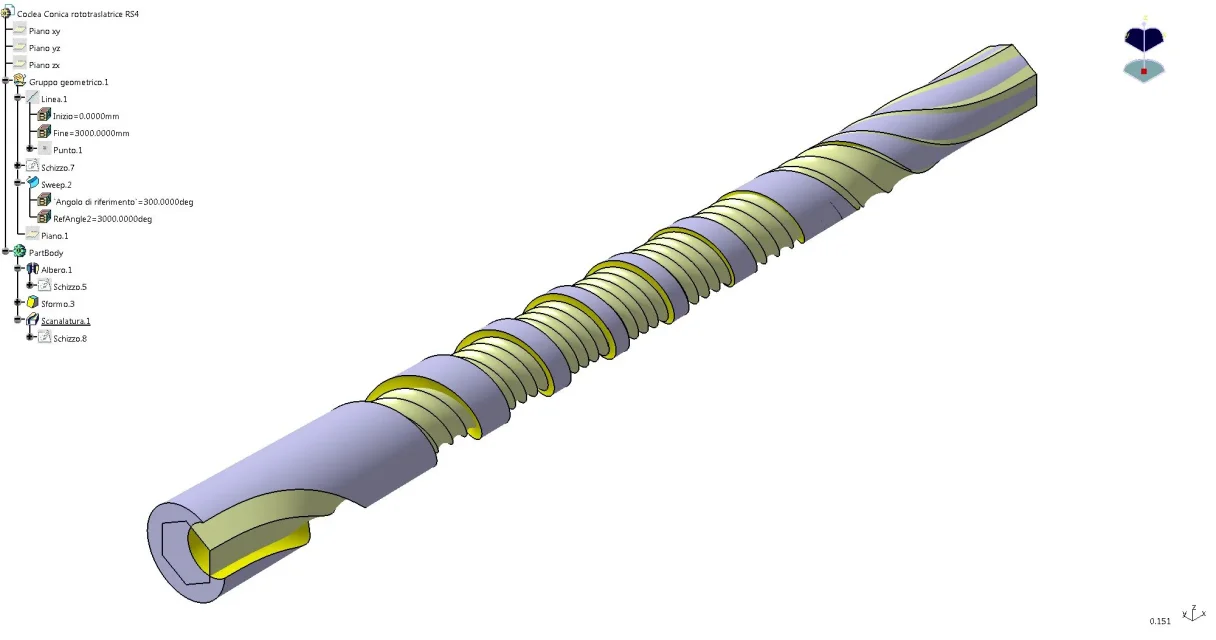

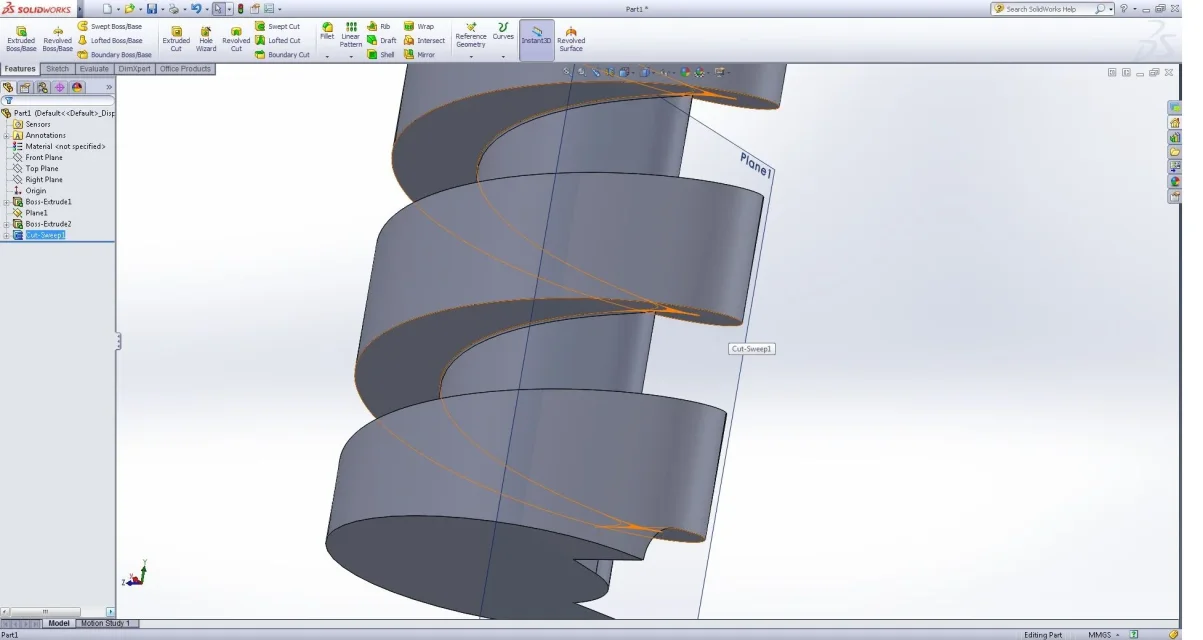

- As for the first part (separation from the line) I drew a spiral with 3 different steps for 3 revolutions on the surface of the cylinder and carried out a sweep of the solid (not rotated, then with the long side almost parallel to the axis of the axle).

I discovered later (after several imprecations) that if the spiral is not centered on the tool outside those malice artifacts, moving the spiral on the center of the tool (no longer on the surface of the cochlea) I get a more realistic geometry:

I discovered later (after several imprecations) that if the spiral is not centered on the tool outside those malice artifacts, moving the spiral on the center of the tool (no longer on the surface of the cochlea) I get a more realistic geometry:

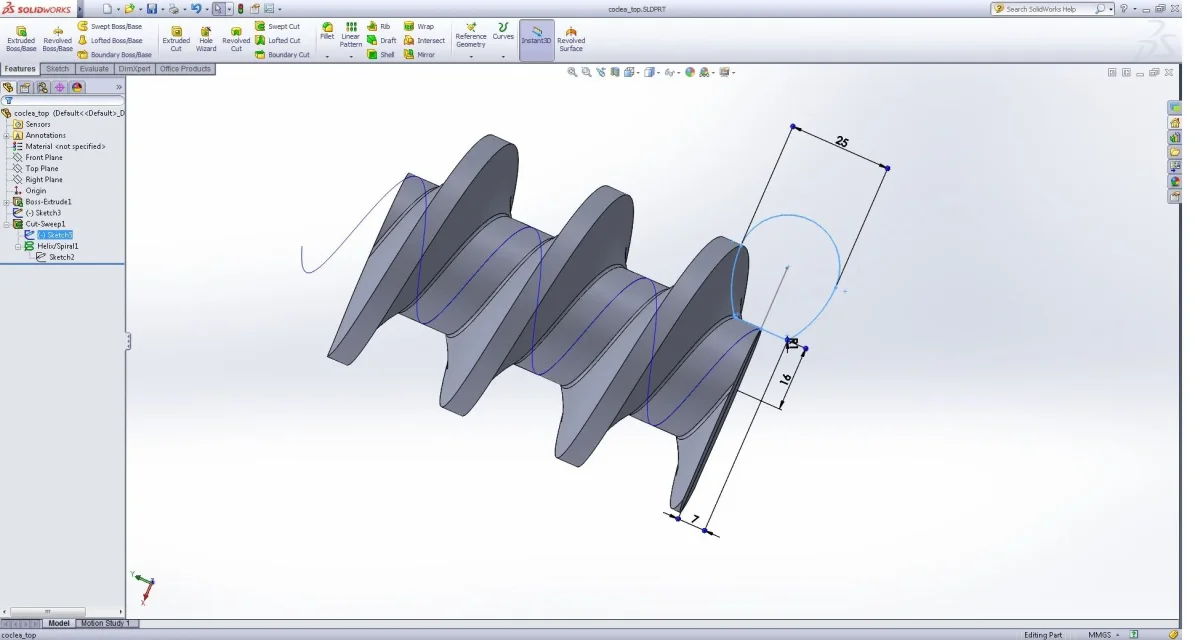

View attachment 2899 - for the final part (only translation) I always made a solid cut-sweep

I initially tried with a cut-sweep of the solid in question rotated of 90 degrees (then the step is inferior), but the result does not represent the reality' (though it follows the indications that there are in the mega-thread on the extrusion of the

are then passed to a cut-sweep following a fairly invented profile:

are then passed to a cut-sweep following a fairly invented profile:

It's not very accurate, but you should do your job.

It's not very accurate, but you should do your job.

the central part of the auger to rotate the piece I have absolutely no ideas on how to reproduce it.

exists a way to tell the tool (solid) that must follow a trajectory along a spiral, but which must also rotate in the meantime?

other questions, but not so serious and/or important, all about the first part of the cochlea:

the cut sweep seems not to go on if after 360 degrees the tool touches the track of the turn before, blocking the cut some degree before (not finishing the revolution then). Is there a way to bypass this limit? the actual coclea has the diameter cut for this reason.

solving the question before, is it possible to give the spiral a growing step without having to give it "discreetly"?

Finally, it is possible to indicate to swx a second direction for the spiral in order to have an extrusion also on the other side to "complete" the coclee?

thanks for any answers

Good day