Andrea - Overcam

Guest

Yes, but you can write straight into the cartiglio and automatically create its property in the drawing file.I ask if it is possible in the field cartilages that are not the standard ones in the properties: I explain... for each sheet file, I must indicate the treatment in the cartilage under the material. I don't find the right property and if I do one, then it just stays in that file.

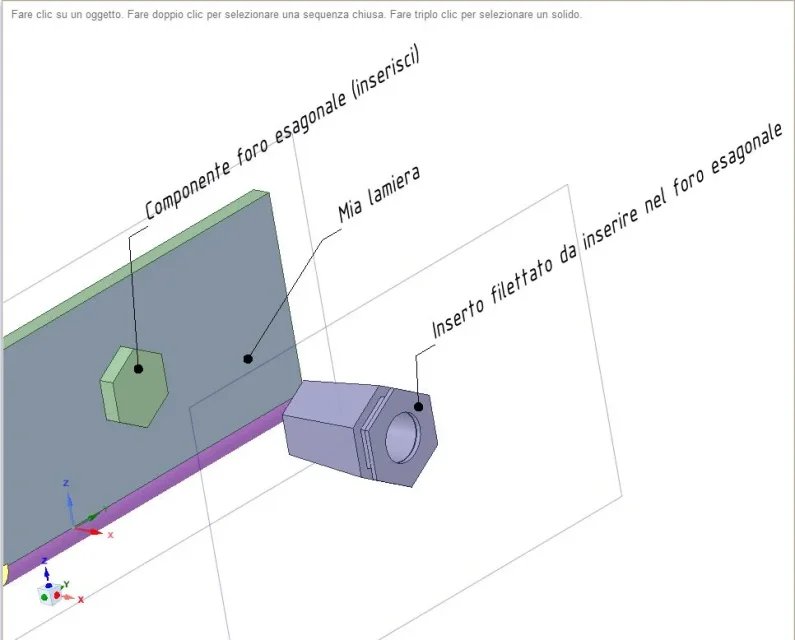

I'm not sure I understand. Do you want to create hexagonal holes? Did you try sheet metal with "forms"? There should be customized shapes, a click on the hole center and get the desired shape.if I have to insert hexagonal thread inserts to pull, it takes a hexagonal hole for ognun insert: I made myself a hexagon-shaped component that they posiziono and then with comb, cut off the hexagon; inside the hexagon hole then, I put the insert. Is there any other way?

no, I'm afraid not, the paper is editable only if you open it, not in the drawing sheet itself in real time... I don't think of any solution right now. I'll tell you!once made a custom table format, then when I make a table, can you no longer change? For example if the code field is too short because in the current case I have a longer code, how do I get it back into its space that I can't marry anymore?