meccanicamg

Guest

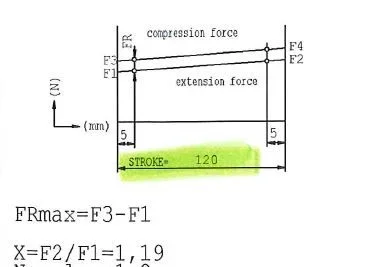

in the sense that the prevailing force is the one that makes the gas piston stretch. when the arms are disadvantageous to the piston, it fails to push enough and therefore contracts to win the forces at stake that are superior to its reaction. the push force is about constant of the piston. depending on the working geometry raises or lowers, pushes or pulls....but in the end he always pushes: so much or little in its range but physically it will never draw towards the center but yields.