TETRASTORE

Guest

I would not put either of them, being a worked plan; here however you should think what will be the initial state of the crude and how this piece will be worked.I wanted to ask you one last thing: according to you is necessary a tolerance of flatness (and/or a narrower roughness) on the right side of the plate on which the shouldering of the pin rests before the entrance to the conical hole?

I would also have great perplexity to maintain both the pin and the conical centering because as already mentioned in the case of the centering, it will be difficult to make them work at the same time.

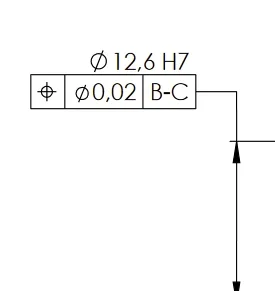

personally on this side I would prefer the bar and the cylindrical pin; In this way you can lock the screws by axially blocking and centering the pin by pressing it on the right conical part. However, the problem of the 12h7 centring remains with the pin of the counterpiece that touches in the head.

You could solve in this way: the ends of the pins and relative seats the cylindrical dots, I would shorten the right counterpiece so that you can apply a screw at the head of the pin (left) to prevent it from slipping while its position is maintained by the already present bar. in this way you can go to line with the centering 12 h7.- I think I understand what you mean in the third point, but I don't know how to solve the problem: the conical hole I need for connection between the left plate and the pin that supports the hammer holder, while the other hole is necessary to connect the left plate with the right plate of the hammer holder and therefore designed to ensure greater stability.