jno

Guest

Hello to all of the forum.

:smile: I ask if there is a possibility of exchange favors on bares or around.

I leave from (under) zero....

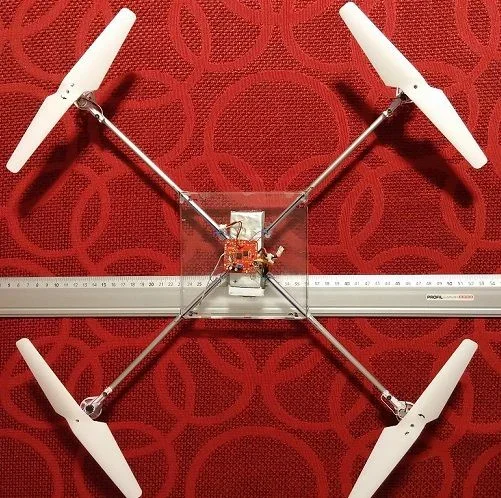

I can scan high resolution of objects up to 45x45x100 cm practically every day.

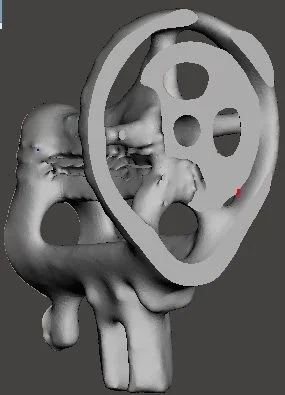

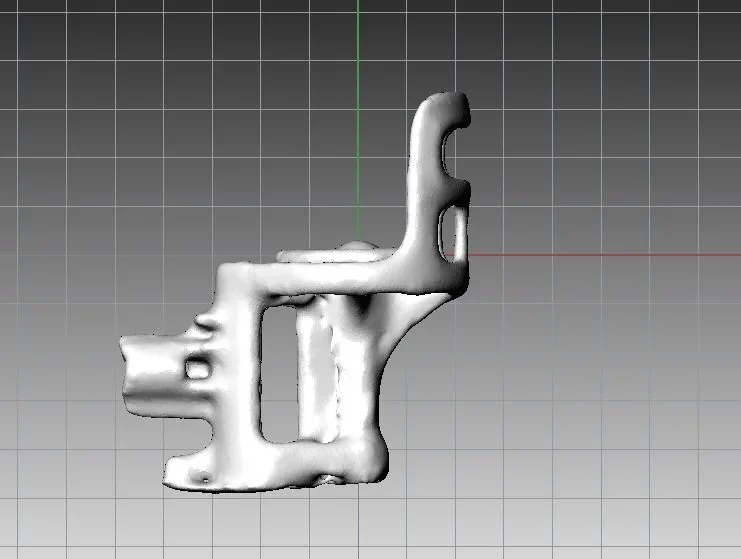

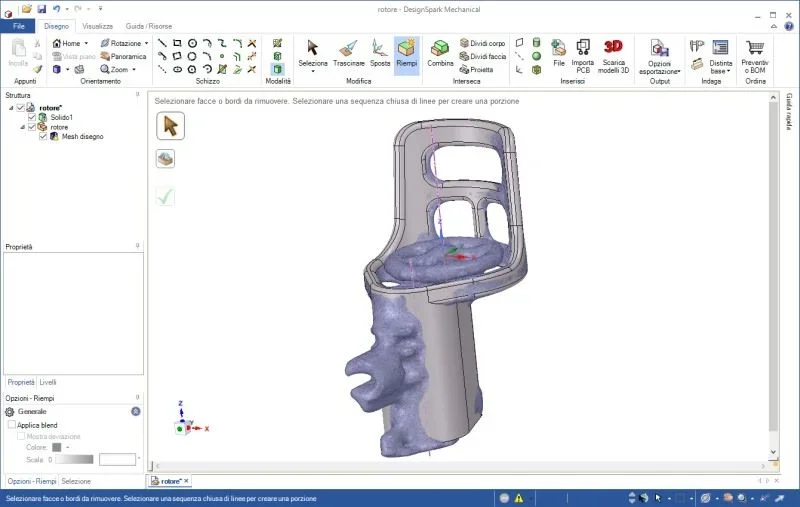

being at first I tried to make smart and convert a plastic object from dicom to stl

to be able to import it into a cad to vary its measurements, this is what I need.

(The object is disarming simplicity, but my ignorance of the newly downloaded programs is not just: )

x-ray scanning allows to have also the inner part scanned objects,

Usually you search this feature for mechanical objects.

monthly I can also perform unusual scans of 55x55x200 cm depending on weight.

in the first test I used an acquisition with these parameters:

80 kv, 30mas, 64 x 0.625 mm per slice, 5x5 cm of fov, in pure axial

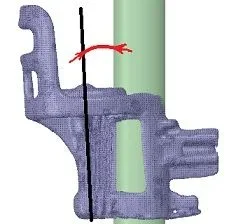

with noise reduction metal parts (the object has a metal shaft)

and reduction of noise during reconstruction of dicom images

owner of the equipment I assist.

the resulting dicom file travels on the 185 mb and the stl file on the 150 mb, but it is precisely on the conversion that I have problems,

I have to generate a decent file to send to any press center.

the exchange I propose would be to perform scans for those who need it

and receive appropriate instructions on the use of 3dslicer for the correct conversion to stl.

(I also downloaded meshlab, meshmixer and designpark)

Moreover, finding the correct parameters and steps also serves to those who then ask me for scans.

(you will find yourself with the same problem )

I can always monthly increase scanning quality to 0.3 mm slice in pure axial

or down to 0.1mm in volumetric acquisition.

:smile: Hopefully I guessed the right section I expect some constructive response

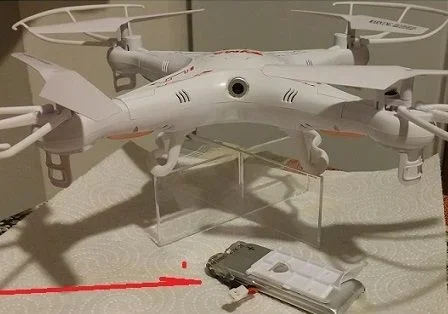

Of course I can attach photos of the object, what it takes etc.

p.s. to the fans: have mercy on my ignorance, I would like to learn.

:smile: I ask if there is a possibility of exchange favors on bares or around.

I leave from (under) zero....

I can scan high resolution of objects up to 45x45x100 cm practically every day.

being at first I tried to make smart and convert a plastic object from dicom to stl

to be able to import it into a cad to vary its measurements, this is what I need.

(The object is disarming simplicity, but my ignorance of the newly downloaded programs is not just: )

x-ray scanning allows to have also the inner part scanned objects,

Usually you search this feature for mechanical objects.

monthly I can also perform unusual scans of 55x55x200 cm depending on weight.

in the first test I used an acquisition with these parameters:

80 kv, 30mas, 64 x 0.625 mm per slice, 5x5 cm of fov, in pure axial

with noise reduction metal parts (the object has a metal shaft)

and reduction of noise during reconstruction of dicom images

owner of the equipment I assist.

the resulting dicom file travels on the 185 mb and the stl file on the 150 mb, but it is precisely on the conversion that I have problems,

I have to generate a decent file to send to any press center.

the exchange I propose would be to perform scans for those who need it

and receive appropriate instructions on the use of 3dslicer for the correct conversion to stl.

(I also downloaded meshlab, meshmixer and designpark)

Moreover, finding the correct parameters and steps also serves to those who then ask me for scans.

(you will find yourself with the same problem )

I can always monthly increase scanning quality to 0.3 mm slice in pure axial

or down to 0.1mm in volumetric acquisition.

:smile: Hopefully I guessed the right section I expect some constructive response

Of course I can attach photos of the object, what it takes etc.

p.s. to the fans: have mercy on my ignorance, I would like to learn.